A Dow executive discusses end-market potential for recovered flexible films, and an article explores the challenges of recovering plastics from toys.

A Dow executive discusses end-market potential for recovered flexible films, and an article explores the challenges of recovering plastics from toys.

A Dow executive discusses end-market potential for recovered flexible films, and an article explores the challenges of recovering plastics from toys.

A Dow executive discusses end-market potential for recovered flexible films, and an article explores the challenges of recovering plastics from toys.

A French chemical company has announced industrial-scale production of a recycled polyamide 6.6 resin made from airbag fabrics.

A French chemical company has announced industrial-scale production of a recycled polyamide 6.6 resin made from airbag fabrics.

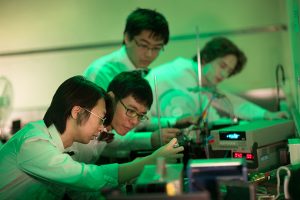

Copyright Imperial College London, Thomas Angus, 2017.

A team of college students in the U.K. is developing a low-cost instrument to allow manual sorters to quickly recognize different resins.

Idea-Tec is currently recycling about five tons of EPS per month, producing 25 tons of paint.

Two Chilean chemists are commercializing a technology they developed to recycle expanded polystyrene into paint.

Several technologies for processing post-consumer PET into food and drink packaging have been approved. | srisakorn wonglakorn/Shutterstock

A food-safety panel approved 17 applications to use Starlinger, SML and Protec technologies to recycle post-consumer PET into food and drink packaging. It rejected two other requests.

Extruded opaque sheet of thermoplastic from printed film scrap (left) and translucent sheet produced through a supercritical CO2 extrusion process. | Courtesy of AIMPLAS

A form of pressurized carbon dioxide can be used to remove contaminants from post-consumer plastic melt, improving the quality of the final pellets, according to a research organization.

As part of the pilot project, Magnomer’s magnetizable inks were printed on shrink labels in collaboration with American Fuji Seal. | Courtesy of Magnomer

A startup that supplies an ink allowing shrink sleeve labels to be separated from PET flakes with a magnet has successfully completed early testing of the innovation.

The Association of Plastic Recyclers recently issued several letters to packaging companies recognizing their innovations as compatible with plastics recycling processes. | Trong Nguyen/Shutterstock

A slew of packaging products – a plastic aerosol can, multi-layer HDPE bottle, bottle and film labels – recently received recognition for their compatibility with plastics recycling processes.

A solvent-based recycling process successfully de-inks LDPE film samples, and an equipment provider releases an updated line of melt filter products for compounding.

A solvent-based recycling process successfully de-inks LDPE film samples, and an equipment provider releases an updated line of melt filter products for compounding.

Two industry veterans recently spoke about scrap plastics supply conditions and typical practices at recycling facilities. | Maciej Bledowski/Shutterstock

A pair of longtime plastics recycling professionals discussed melt filtration advancements, deodorizing processes, bale supply issues and more during a recent webinar.