This story has been updated.

This story has been updated.

A consumer of recovered PE film will spend about $200 million in the next couple of years to boost its production capacities.

Associate Editor Jared Paben has worked for Resource Recycling since December 2014. Most of his earlier career was spent as a reporter for the daily newspaper in Bellingham, Wash., but he also has experience working for the Oregon volunteerism commission and for Oregon nonprofits serving low-income populations. He can be contacted at [email protected].

Associate Editor Jared Paben has worked for Resource Recycling since December 2014. Most of his earlier career was spent as a reporter for the daily newspaper in Bellingham, Wash., but he also has experience working for the Oregon volunteerism commission and for Oregon nonprofits serving low-income populations. He can be contacted at [email protected]. This story has been updated.

This story has been updated.

A consumer of recovered PE film will spend about $200 million in the next couple of years to boost its production capacities.

An Italian company that recycles post-consumer nylon will spend over $40 million to acquire a North Carolina fiber manufacturer.

Colgate-Palmolive has developed a toothpaste tube that passed tests for sortability by materials recovery facilities and processability by plastics reclaimers.

Colgate-Palmolive has developed a toothpaste tube that passed tests for sortability by materials recovery facilities and processability by plastics reclaimers.

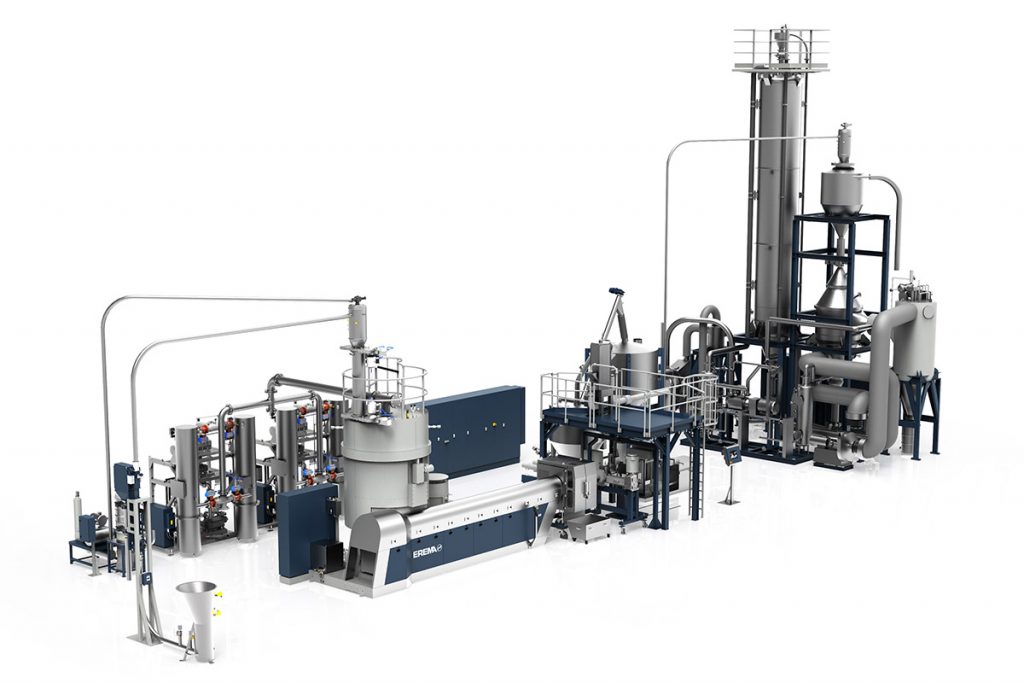

A new PET recycling system combines decontamination approaches from two different European equipment providers.

A new PET recycling system combines decontamination approaches from two different European equipment providers.

Researchers have developed an improved version of a desktop extruder that produces filament for 3D printers, and they’ve made assembly instructions available online for free.

Researchers have developed an improved version of a desktop extruder that produces filament for 3D printers, and they’ve made assembly instructions available online for free.

If PET is PET is PET to a standard optical sorter, Tomra’s new Sharp Eye technology isn’t standard.

For more than two decades, Erema’s Laserfilter has been used to remove contaminants from polyolefin melt streams. A year ago, the company released a PET version, and the market interest has been strong, according to the Austria-headquartered company.

Flake-washing equipment from Italian equipment company Amut removes contaminants from flake via centrifugal force.

Flake-washing equipment from Italian equipment company Amut removes contaminants from flake via centrifugal force.

A new melt filter from Ettlinger is designed for handling heavily contaminated plastic loads and achieving high throughputs.

A new melt filter from Ettlinger is designed for handling heavily contaminated plastic loads and achieving high throughputs.

A crystallization dryer from EREMA allows PET reclaimers to retrofit their existing lines to sell into the higher-value food and drink packaging sectors.

A crystallization dryer from EREMA allows PET reclaimers to retrofit their existing lines to sell into the higher-value food and drink packaging sectors.