Trucks outside ERI’s Fresno, Calif. recycling facility.

ERI is using machinery with artificial intelligence to sort materials coming out of a shredder. It’s the first publicly known case of an AI robotic system sorting e-scrap.

Trucks outside ERI’s Fresno, Calif. recycling facility.

ERI is using machinery with artificial intelligence to sort materials coming out of a shredder. It’s the first publicly known case of an AI robotic system sorting e-scrap.

The U.S. Department of Energy will award $5.5 million to companies advancing lithium-ion battery recycling technology, and it will dedicate $15 million to developing a research center focused on the material.

The U.S. Department of Energy will award $5.5 million to companies advancing lithium-ion battery recycling technology, and it will dedicate $15 million to developing a research center focused on the material.

In Uganda, end-of-life cell phones are collected before being shipped for recycling.

Tech companies are seeing boosted demand for environmental leadership, and e-scrap management concerns continue to mark developing countries. An enterprise in Europe is working to help out on both fronts.

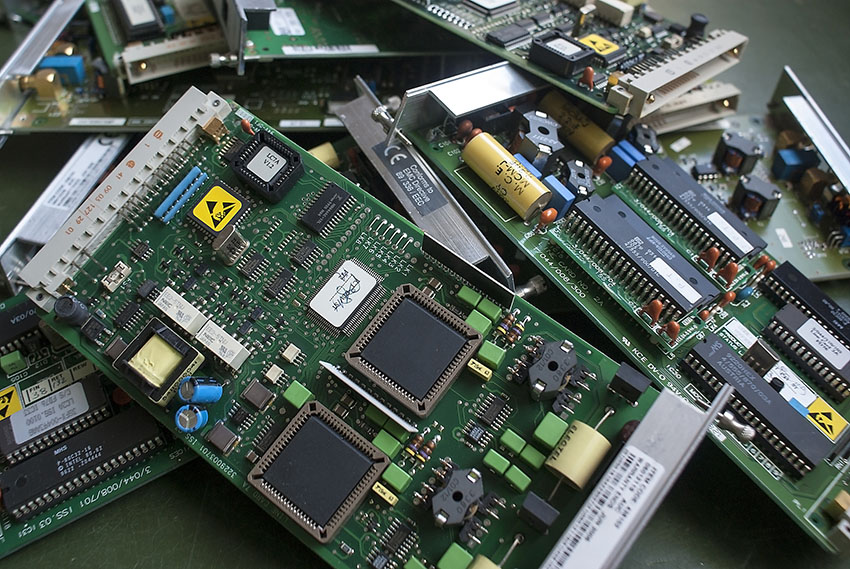

A metals company will expand capacity at a Swedish copper smelter that consumes substantial volumes of printed circuit boards.

A metals company will expand capacity at a Swedish copper smelter that consumes substantial volumes of printed circuit boards.

A Canadian e-scrap technology company has received over $700,000 after pitching its hydrometallurgical process on a reality TV show.

A Canadian e-scrap technology company has received over $700,000 after pitching its hydrometallurgical process on a reality TV show.

Global e-scrap flows have helped China dominate lithium-ion battery recycling but have hampered similar efforts in North America, according to a recently published report.

This story has been updated.

This story has been updated.

Bathroom doors, a water cooler handle, a refrigerator – their surfaces carried lead, cadmium and other hazardous metals, according to studies at two e-scrap facilities.

Startup EnviroLeach has raised its precious metals yield capabilities and has moved forward on developing new e-scrap processing plants.

Startup EnviroLeach has raised its precious metals yield capabilities and has moved forward on developing new e-scrap processing plants.

Several minerals used in electronics were recently deemed critical to the economic and national security of the U.S.

Several minerals used in electronics were recently deemed critical to the economic and national security of the U.S.

Sellers of scrap circuit boards have seen lower price quotes in recent weeks.

Sellers of scrap circuit boards have seen lower price quotes in recent weeks.