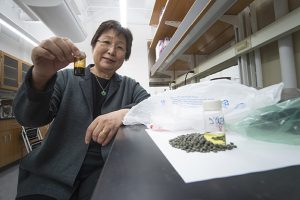

Purdue University professor Linda Wang shows the oil product from a new polyolefin-to-oil conversion process.

A team at Purdue University has developed a unique method for converting scrap polyolefins into oil, fuels or monomers for use in new plastics.

Mixed plastics and recovered carpet aren’t usually the preferred feedstock for product manufacturers. But a Texas company making wood alternatives for the construction sector is building its business around those very materials.

Mixed plastics and recovered carpet aren’t usually the preferred feedstock for product manufacturers. But a Texas company making wood alternatives for the construction sector is building its business around those very materials. With an eye toward the highest level of recycled plastic purity, Ettlinger has introduced a new model of its ECO melt filter, this time targeting contaminants as small as 60 microns.

With an eye toward the highest level of recycled plastic purity, Ettlinger has introduced a new model of its ECO melt filter, this time targeting contaminants as small as 60 microns. A number of companies have announced developments in technologies for breaking down plastics for use in other products. Here are a few of the notable news items.

A number of companies have announced developments in technologies for breaking down plastics for use in other products. Here are a few of the notable news items. In Europe, scientists say they’ve developed a fast and accurate way for near-infrared sorters to classify different plastics containing flame retardants.

In Europe, scientists say they’ve developed a fast and accurate way for near-infrared sorters to classify different plastics containing flame retardants. Forty finalists have been announced for the second Plastics Recycling Awards Europe, and many are using cutting-edge technologies.

Forty finalists have been announced for the second Plastics Recycling Awards Europe, and many are using cutting-edge technologies. Researchers in Spain are exploring the use of enzymes to deodorize recycled plastics from food packaging.

Researchers in Spain are exploring the use of enzymes to deodorize recycled plastics from food packaging. Flexible packaging isn’t going away anytime soon, and an upcoming pilot project seeks to ensure it doesn’t go to landfill.

Flexible packaging isn’t going away anytime soon, and an upcoming pilot project seeks to ensure it doesn’t go to landfill.