Federal funding will target e-scrap separation for metals and plastics recovery. | Jer123 / Shutterstock

A government-backed institute that has funded e-scrap recycling research in recent years is accepting applications for another round of grants.

Federal funding will target e-scrap separation for metals and plastics recovery. | Jer123 / Shutterstock

A government-backed institute that has funded e-scrap recycling research in recent years is accepting applications for another round of grants.

Researchers discovered employees working near an e-scrap shredder had elevated levels of lead in their blood. | Jarun Ontakrai/Shutterstock

This story has been updated.

Testing at a New England e-scrap facility showed that two employees working near a granulator were being overexposed to airborne silver particles.

Discarded electronics are estimated to reach 122 million short tons per year around the globe by 2050. | Petra Nowack/Shutterstock

A United Nations-backed study predicts massive growth in global tonnages of end-of-life electronics, and it examines how the recycling sector can best prepare.

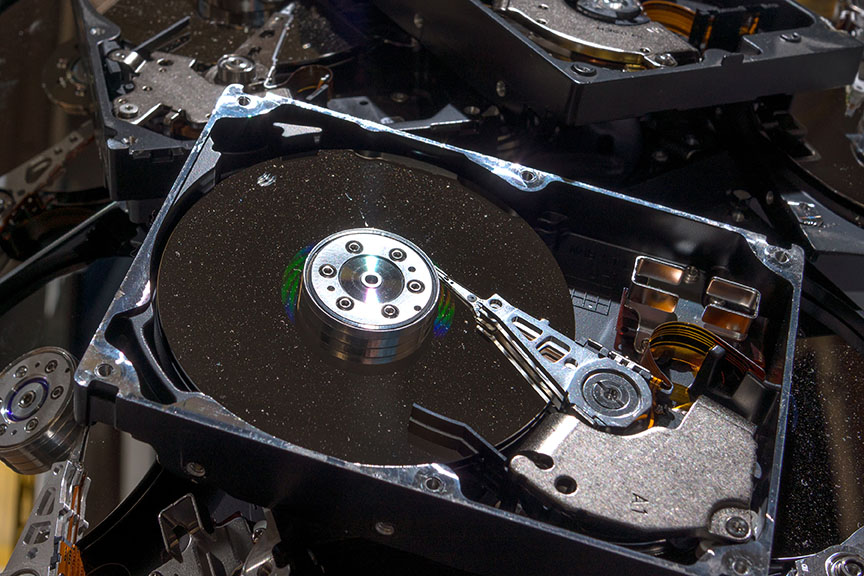

Recycling of rare earth metals has drawn greater attention in the e-scrap industry in recent years. | stuphipps/Shutterstock

European Union grant money will fund a rare earth metals recycling project in the U.K. The planned pilot facility will target magnets found in hard drives and other devices.

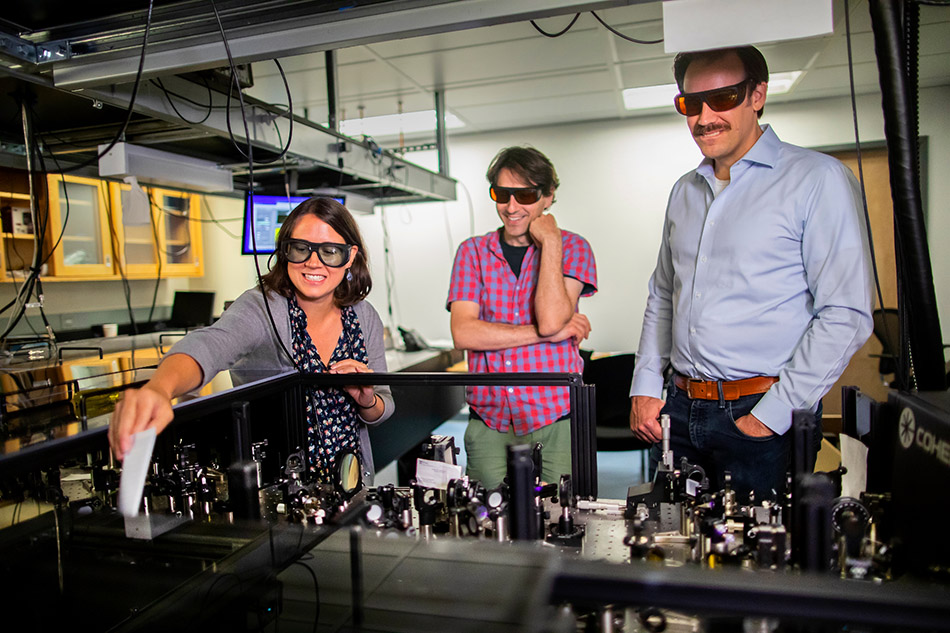

Using a state-of-the-art laser facility, University of Pennsylvania chemists will research how they can use kinetics in e-scrap metal separation strategies. | Photo courtesy University of Pennsylvania.

A $1.8 million grant from the National Science Foundation will support research into better separation of metals in consumer electronics.

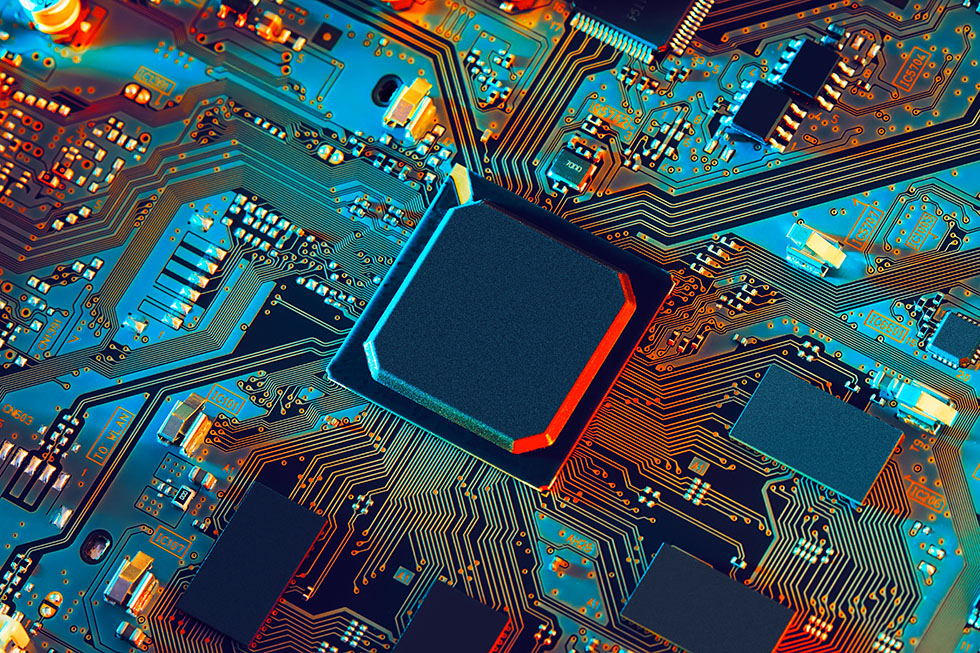

The company’s process uses microorganisms to scavenge precious metals from circuit boards. | raigvi/Shutterstock

An e-scrap firm using microbes to recover metals from electronic scrap has launched a processing facility to demonstrate its technology.

Several of the most popular older Apple iPhone models may be losing favor among consumers, an analysis suggests.

Several of the most popular older Apple iPhone models may be losing favor among consumers, an analysis suggests.

Pulsed electricity has proven a powerful tool in separating e-scrap into clean material streams, according to recent findings from a Japanese university.

Pulsed electricity has proven a powerful tool in separating e-scrap into clean material streams, according to recent findings from a Japanese university.

An e-scrap processor is installing a robotic sorting cell to take apart hard drives and recover each component of the device.

An e-scrap processor is installing a robotic sorting cell to take apart hard drives and recover each component of the device.

An industry group has identified six advanced recycling projects that target plastics from electronics. One of the tech developers is a prominent North American e-scrap processor.

An industry group has identified six advanced recycling projects that target plastics from electronics. One of the tech developers is a prominent North American e-scrap processor.