Outerwall, the parent of electronics trade-in company ecoATM, is merging with a private equity firm and will no longer be a publicly traded company.

Outerwall, the parent of electronics trade-in company ecoATM, is merging with a private equity firm and will no longer be a publicly traded company.

Outerwall, the parent of electronics trade-in company ecoATM, is merging with a private equity firm and will no longer be a publicly traded company.

Outerwall, the parent of electronics trade-in company ecoATM, is merging with a private equity firm and will no longer be a publicly traded company.

In his apology, Sonos CEO Patrick Spence pledged the company would keep legacy products updated with bug fixes and security patches for as long as possible. | ClassyPictures/Shutterstock

The leader of electronics manufacturer Sonos apologized amid controversy over his company’s decision to end software updates for old smart speaker systems, assuring customers the devices won’t become obsolete.

Cascade’s annual report includes data the company collected on the 560,000 assets it processed in 2018 and 2019. | fizkes/Shutterstock

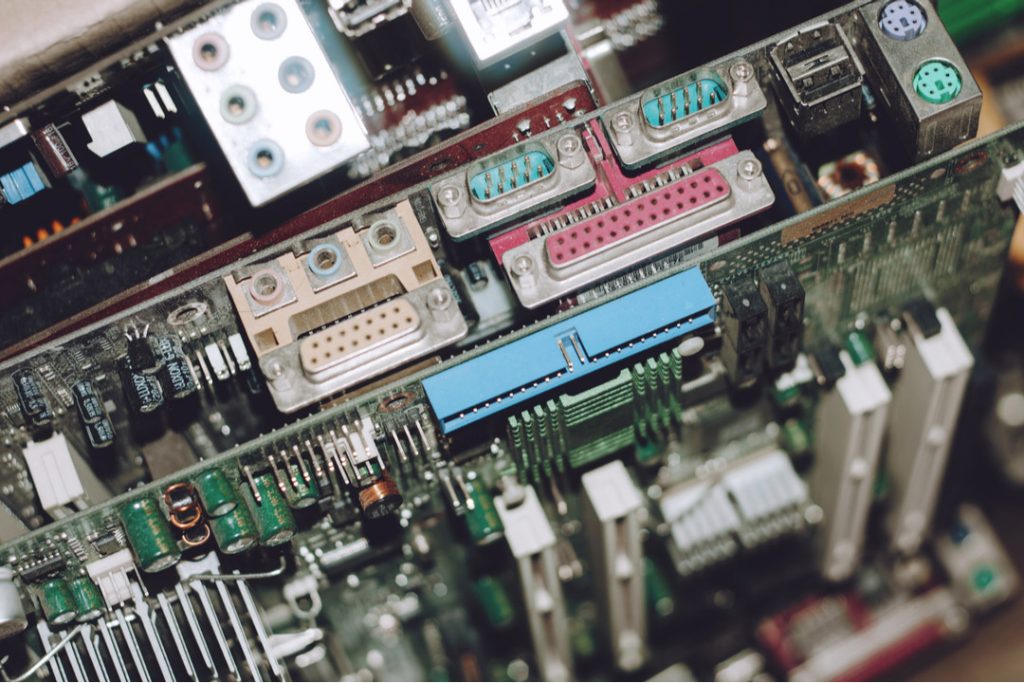

Resale values for used computers declined in 2019 after multiple years of increases, according to an ITAD firm. One possible culprit is generators opting for device destruction over data wiping.

NovoTec has already begun shipping glass to the new destinations. | HomeArt/Shutterstock

NovoTec Recycling finalized contracts to ship CRT glass to smelters in British Columbia and South Korea. The total glass capacity is greater than what NovoTec sent to Glencore’s now-closed smelter.

Lithium-ion batteries have caused numerous fires around the country, both in e-scrap facilities and in materials recovery facilities. | Mehaniq/Shutterstock

An e-scrap firm recently described the fire hazard lithium-ion batteries present and emphasized the importance of identifying and properly handling them.

4L Holdings, the parent company for Clover Wireless, voluntarily filed for Chapter 11 bankruptcy in December. | TheaDesign/Shutterstock

A major North American phone repair and remarketing company has received court approval to restructure its debt, allowing it to come out of bankruptcy in the coming days.

In Olympia, Wash., right-to-repair proponents and opponents testified during a Jan. 21 hearing in front of the Senate Environment, Energy & Technology Committee. | jfergusonphotos/Shutterstock

Electronics repair stakeholders clashed over right-to-repair legislation in Washington state this week, as a number of state legislatures begin taking up similar bills.

In April, the Chinese government will enact new requirements for pellet imports. | Piyathep/Shutterstock

Officials in Beijing are set to enact new requirements around the purity of recycled plastic pellets imported into China, which could disrupt international markets for U.S. e-plastics.

Continue Reading

Wisconsin is considering requiring most e-scrap processing facilities to obtain solid waste processing licenses. | Iryna Imago/Shutterstock

Wisconsin regulators are drafting rules that would require additional electronics recycling processors to set aside money for facility closure and cleanup costs.