Republic Services’ recycling business brought in $68.6 million in revenue during the third quarter, down 10% year over year. | Resource Recycling file photo

Some of the largest publicly traded garbage and recycling companies got pinched by recycling markets during the third quarter. Others got flat-out hammered.

A partisan City Council dispute in San Diego threatens a contract with the city’s MRF operator, and Montgomery, Ala.’s mixed-waste MRF is on the way to reopening.

A partisan City Council dispute in San Diego threatens a contract with the city’s MRF operator, and Montgomery, Ala.’s mixed-waste MRF is on the way to reopening.  Injuries at MRFs increased by more than 60 percent in 2017, according to new data from the federal government.

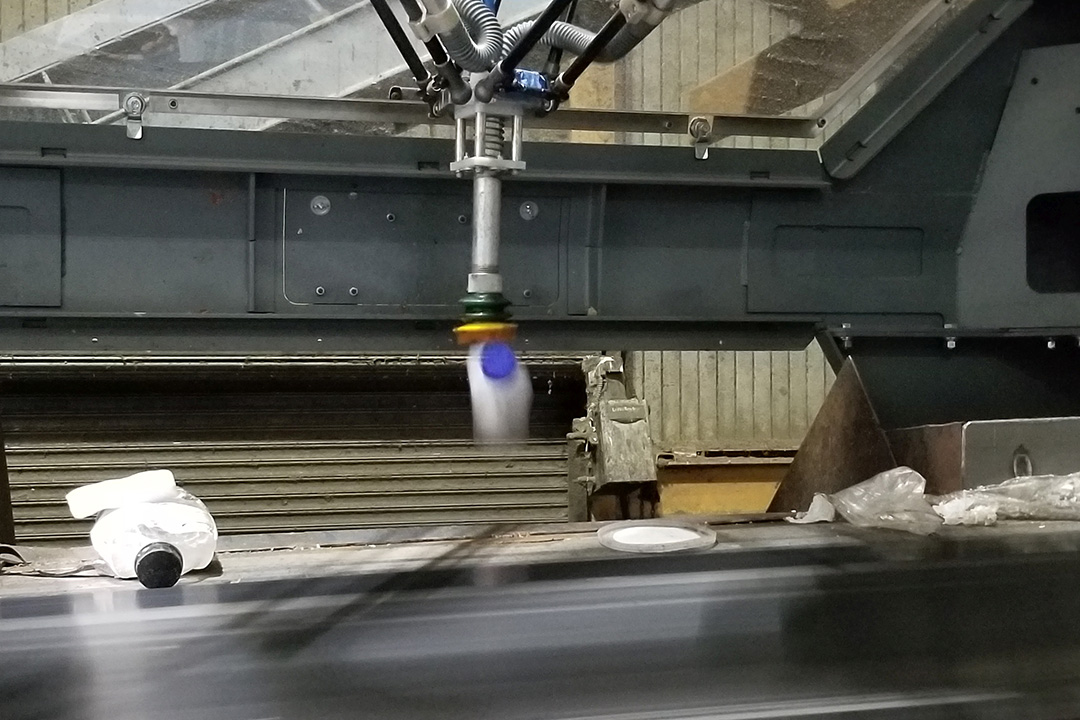

Injuries at MRFs increased by more than 60 percent in 2017, according to new data from the federal government. When it first opened more than a decade ago, the Durham Region Material Recovery Facility (MRF) in Ontario was Canada’s first dual-stream facility to use an optical sorter.

When it first opened more than a decade ago, the Durham Region Material Recovery Facility (MRF) in Ontario was Canada’s first dual-stream facility to use an optical sorter.