Jared Paben outside of ORPET, a PET bottle recycling plant in St. Helens, Ore., in May 2023.

After nine years at Resource Recycling, I have decided to leave to seize life’s next adventure. Continue Reading

Associate Editor Jared Paben has worked for Resource Recycling since December 2014. Most of his earlier career was spent as a reporter for the daily newspaper in Bellingham, Wash., but he also has experience working for the Oregon volunteerism commission and for Oregon nonprofits serving low-income populations. He can be contacted at [email protected].

Associate Editor Jared Paben has worked for Resource Recycling since December 2014. Most of his earlier career was spent as a reporter for the daily newspaper in Bellingham, Wash., but he also has experience working for the Oregon volunteerism commission and for Oregon nonprofits serving low-income populations. He can be contacted at [email protected].

Jared Paben outside of ORPET, a PET bottle recycling plant in St. Helens, Ore., in May 2023.

After nine years at Resource Recycling, I have decided to leave to seize life’s next adventure. Continue Reading

A robot funded by the aluminum industry successfully picked an average of 1,565 UBCs per day, an analysis found. | EWY Media/Shutterstock

A recycling robot installed at a California MRF has recovered an average of 1,565 UBCs per day since it was installed this summer, according to a metal can industry group.

The Can Manufacturers Institute (CMI), which helped finance the installation of the EverestLabs robot at Caglia Environmental’s MRF, is now looking to deploy another unit at another MRF.

“CMI plans to use the learnings from this successful initiative to support additional UBC capture equipment at MRFs, further enhancing the recycling industry’s efficiency,” according to a case study that was published today (Dec. 12). “CMI and EverestLabs are now looking to expand their partnership and are exploring placing a robotic system in another MRF.”

The robot installed at Caglia’s MRF in Fresno, Calif. received financing assistance from CMI members Ardagh Metal Packaging and Crown Holdings. Those companies, which manufacture aluminum beverage cans, financed a two-year equipment lease for Caglia, which has agreed to share 50% of the revenue generated from the UBCs collected by the leased robot.

The system was deployed on the MRF’s last chance line, where its picking priority is UBCs, followed by other containers.

A robot funded by the aluminum industry successfully picked an average of 1,565 UBCs per day, an analysis found. | EWY Media/Shutterstock

A recycling robot installed at a California MRF has recovered an average of 1,565 UBCs per day since it was installed this summer, according to a metal can industry group.

The Can Manufacturers Institute (CMI), which helped finance the installation of the EverestLabs robot at Caglia Environmental’s MRF, is now looking to deploy another unit at another MRF.

“CMI plans to use the learnings from this successful initiative to support additional UBC capture equipment at MRFs, further enhancing the recycling industry’s efficiency,” according to a case study that was published today (Dec. 12). “CMI and EverestLabs are now looking to expand their partnership and are exploring placing a robotic system in another MRF.”

The robot installed at Caglia’s MRF in Fresno, Calif. received financing assistance from CMI members Ardagh Metal Packaging and Crown Holdings. Those companies, which manufacture aluminum beverage cans, financed a two-year equipment lease for Caglia, which has agreed to share 50% of the revenue generated from the UBCs collected by the leased robot.

The system was deployed on the MRF’s last chance line, where its picking priority is UBCs, followed by other containers.

Jared Paben outside of ORPET, a PET bottle recycling plant in St. Helens, Ore., in May 2023.

After nine years at Resource Recycling, I have decided to leave to seize life’s next adventure. Continue Reading

Export figures are following a yearslong trend of decline due to market changes, trade policy and China’s National Sword. | Chenxueting/Shutterstock

The U.S. continued to export less scrap fiber and plastic during the first nine months of this year, with notable drops in paper shipped to India and plastic shipped to Mexico. Continue Reading

Recently published figures from the Northeast Recycling Council unpacked the proportions of materials in curbside recycling bales. | Philip R/Shutterstock

For all the global, national and state-level arguments and policymaking surrounding plastics, paper continues to increase its already-large share of the curbside bin, new data shows. Continue Reading

A grinder at rPlanet Earth in the Los Angeles area. The PET reclaimer recently received a grant from the PET Recycling Coalition. | Courtesy of rPlanet Earth

The PET Recycling Coalition has given grants to three MRFs and a PET reclaimer to help them better recover and recycle post-consumer PET. Continue Reading

North America’s five biggest waste and recycling haulers recently reported their financial numbers. | Philip Lange/Shutterstock

Recovered fiber prices have steadily increased throughout 2023, but for North America’s top five haulers, the recycling business still isn’t what it used to be. Continue Reading

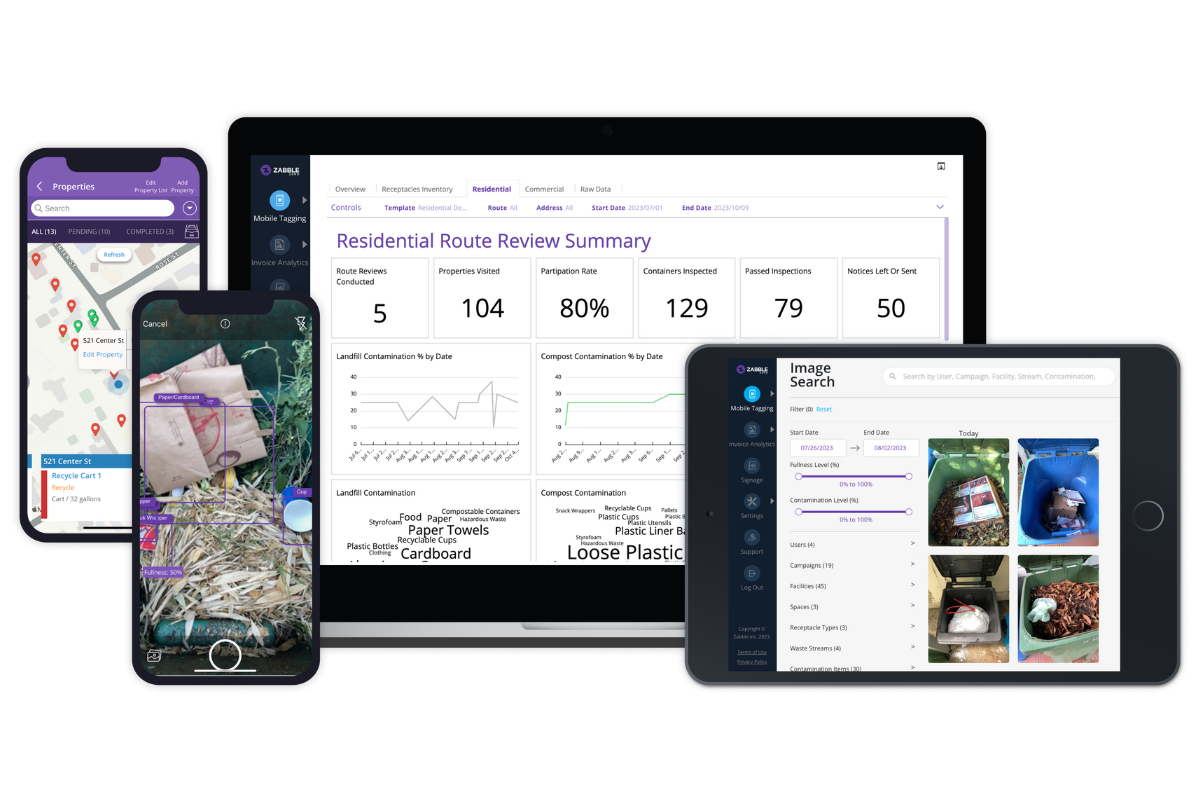

Now that California has mandated organics collection by local governments, Zabble hopes to see growing demand for its contamination monitoring tools. | Courtesy of Zabble

When Zabble interviewed dozens of municipal recycling stakeholders in California, one of the issues the company heard about was the inability to use contamination monitoring mobile device software in the field when there’s no network signal. Continue Reading

The pulper at Total Fiber Recovery in Chesapeake, Va. | Courtesy of Bulk Handling Systems

A mixed paper and OCC pulping operation is nearing completion on the Eastern Seaboard and plans to start producing unbleached recycled pulp in early January, a company owner said. Continue Reading

Virginia Tech is the recipient of a REMADE Institute grant that will support a contamination removal technology for paper recycling. | Andriy Blokhin/Shutterstock

A federally backed research institute has awarded nearly $10 million to projects supporting remanufacturing and recycling, with particularly heavy sums focused on plastics. Continue Reading