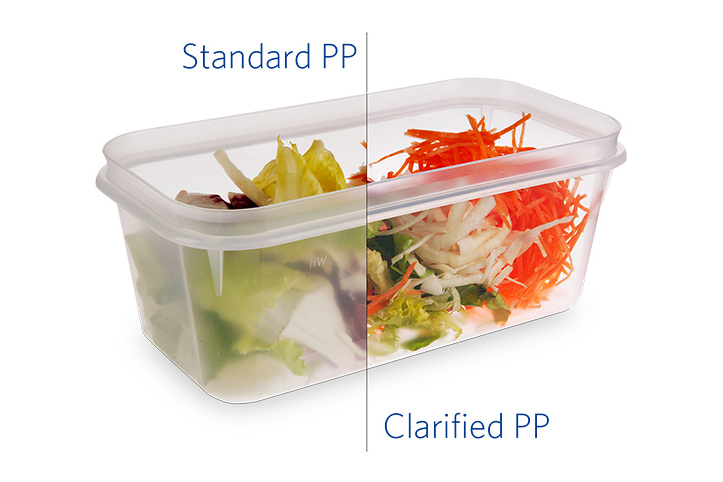

Photo provided by Milliken shows the results of the use of Millad NX 8000 clarifier.

A market-dominating polypropylene clarifier has undergone testing to prove that it neither complicates the plastics recycling process nor harms the finished product.

An integrated plastics reclaimer counters claims about the non-recyclability of black plastics, and a UK company develops a more-efficient plastics-to-oil process using water.

An integrated plastics reclaimer counters claims about the non-recyclability of black plastics, and a UK company develops a more-efficient plastics-to-oil process using water.  After paper recycling companies extract fiber from cartons, they’re often left with a plastic-aluminum mix that’s sent to disposal. An Italian company has begun recycling that mix into pellets.

After paper recycling companies extract fiber from cartons, they’re often left with a plastic-aluminum mix that’s sent to disposal. An Italian company has begun recycling that mix into pellets.