The newly announced additives can improve various qualities of recycled plastics. | Mr_Mrs_Marcha/Shutterstock

Ampacet, ExxonMobil and other producers of additives that boost the quality of recycled plastics have made a number of announcements lately.

Associate Editor Jared Paben has worked for Resource Recycling since December 2014. Most of his earlier career was spent as a reporter for the daily newspaper in Bellingham, Wash., but he also has experience working for the Oregon volunteerism commission and for Oregon nonprofits serving low-income populations. He can be contacted at

Associate Editor Jared Paben has worked for Resource Recycling since December 2014. Most of his earlier career was spent as a reporter for the daily newspaper in Bellingham, Wash., but he also has experience working for the Oregon volunteerism commission and for Oregon nonprofits serving low-income populations. He can be contacted at

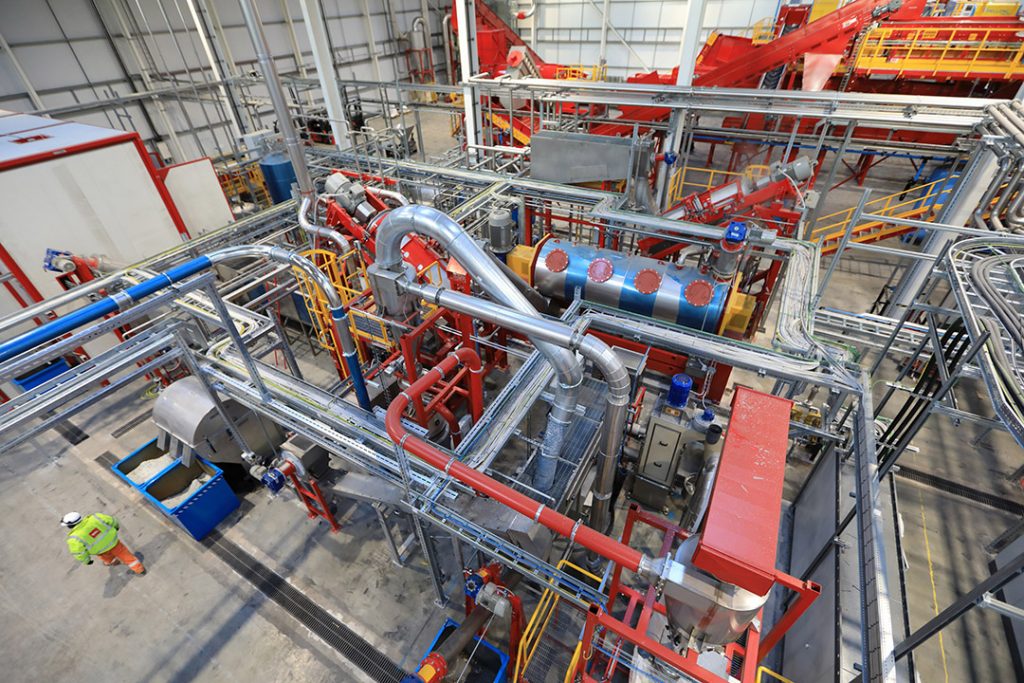

Unilever thinks the key to tackling multi-material flexible packaging waste may be to dissolve, separate and precipitate its PE content so it can be recycled. The giant brand owner plans to test the approach at a facility in East Java, Indonesia.

Unilever thinks the key to tackling multi-material flexible packaging waste may be to dissolve, separate and precipitate its PE content so it can be recycled. The giant brand owner plans to test the approach at a facility in East Java, Indonesia. When added to recycled plastic melt streams, a specially designed particle can break up and scatter contaminants, boost throughputs and help disperse other additives, according to the product’s developer.

When added to recycled plastic melt streams, a specially designed particle can break up and scatter contaminants, boost throughputs and help disperse other additives, according to the product’s developer. As Loop Industries pushes forward its depolymerization method on multi-layer packaging, the startup is also highlighting the potential of recycling opaque PET containers and textiles.

As Loop Industries pushes forward its depolymerization method on multi-layer packaging, the startup is also highlighting the potential of recycling opaque PET containers and textiles.