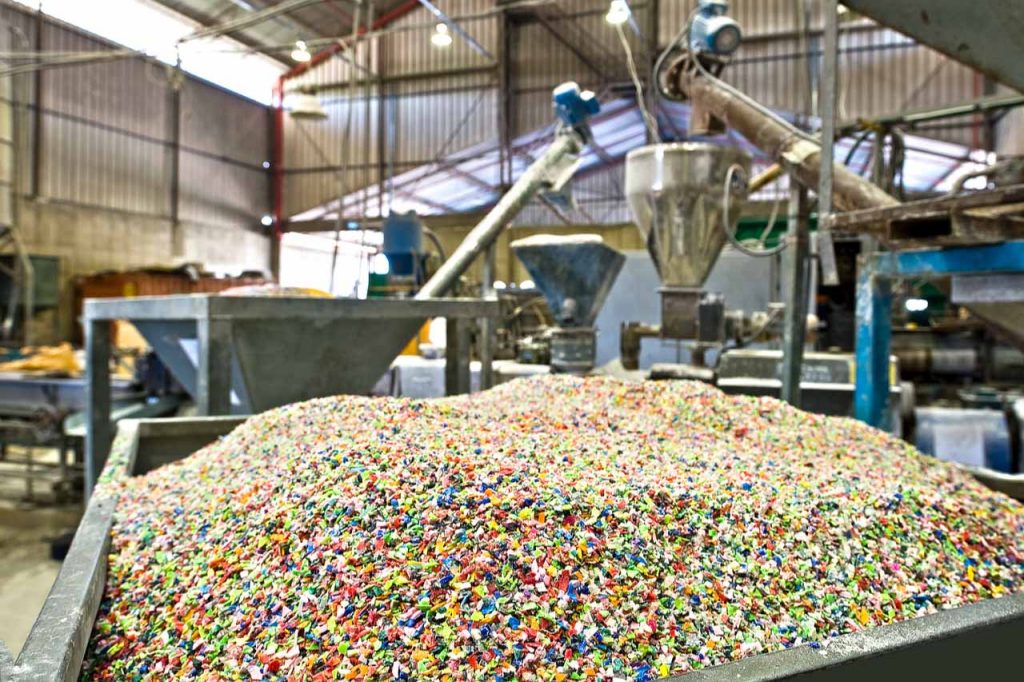

Authorities allege Plastic World Recycling violated several environmental regulations by dumping chemical and cleaning products into a storm drain. | AVN Photo Lab/Shutterstock

A Pennsylvania plastics recycling company has been accused of dumping pollutants into a waterway near its facility.