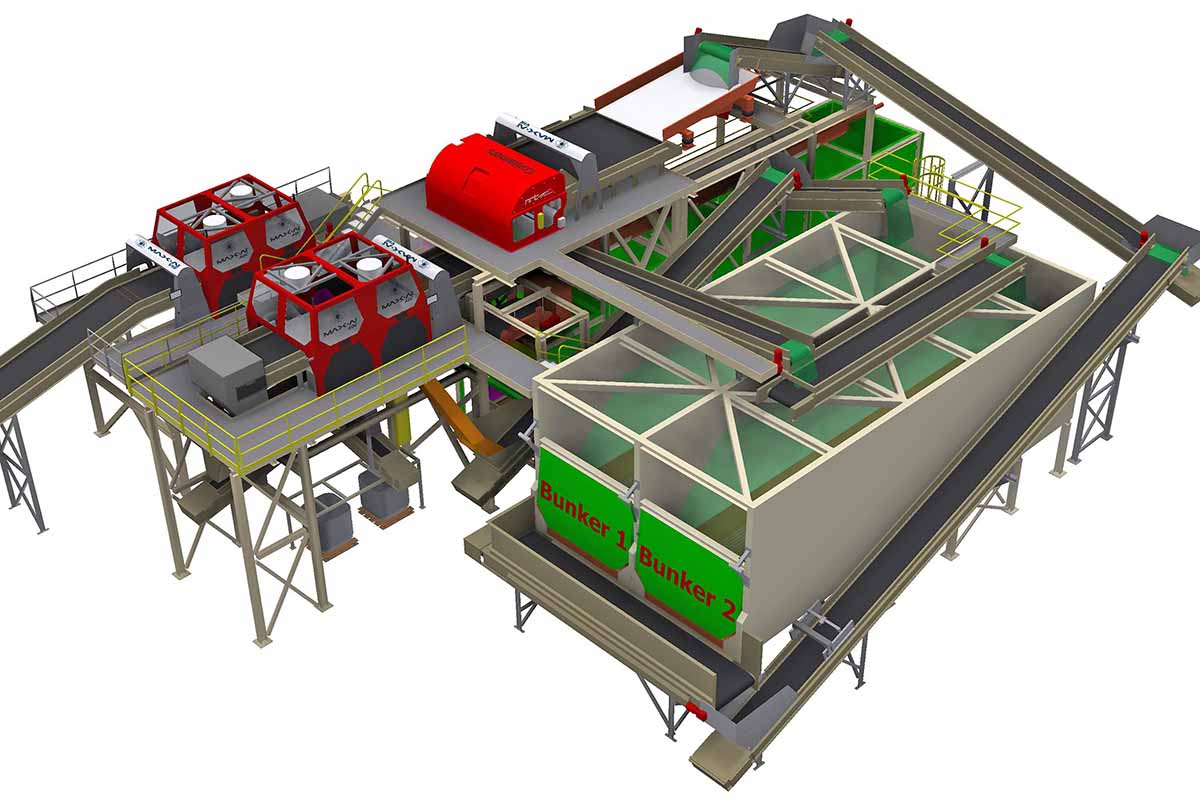

A $6 million MRF upgrade brought in equipment for improved fiber sortation at the Cal-Waste Recovery Systems MRF in Galt, Calif. | Courtesy of CP Group/MSS

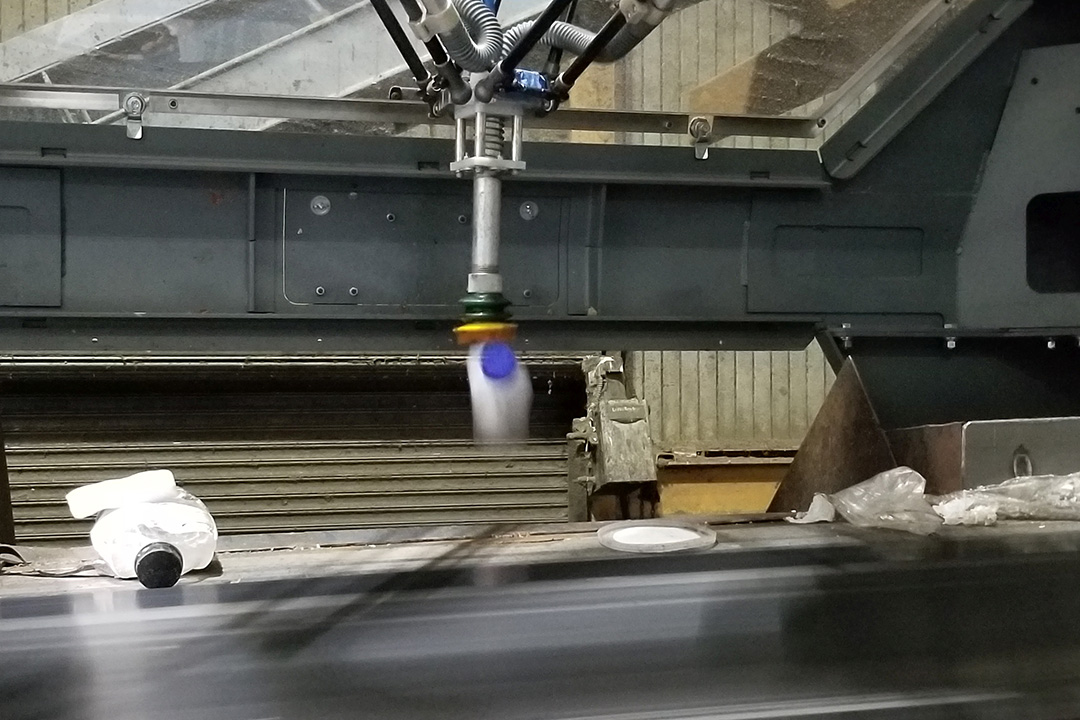

The installation of three dual-eject optical sorters has allowed a Northern California MRF to increase its paper capture rate with a lower headcount, the director of operations said.