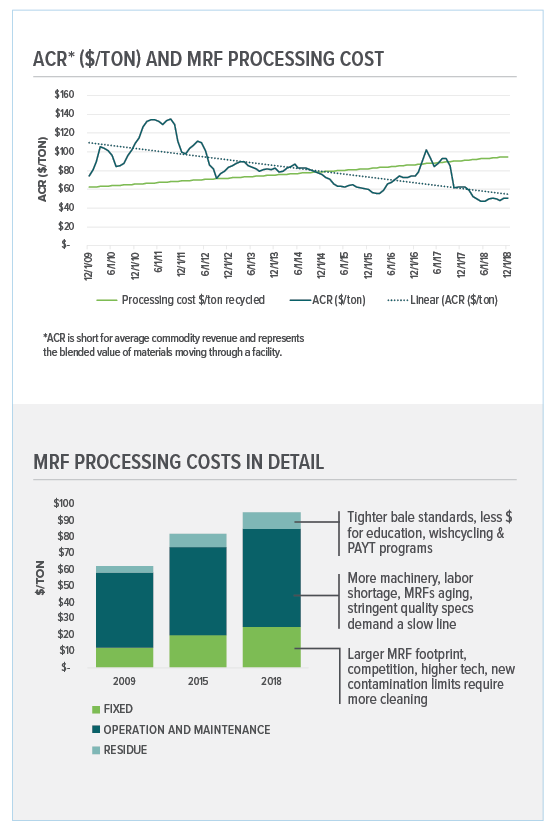

RRS analyzed the various pieces that contribute to processing costs for materials recovery facilities: fixed costs, variable operating and maintenance costs, and the cost of disposing residue. A variety of factors are leading to increases in all of those areas.

MRFs’ fixed costs have more than doubled from 2009 to 2018. This is due to MRFs investing in new technology to stay competitive, adapt to a changing materials stream and meet increasingly stringent bale-quality standards.

Some of the same underlying trends are simultaneously driving up the variable costs that are tied to operation and maintenance. Aging machinery requires more maintenance, and many MRFs have faced labor shortages. Also, MRFs more often run lines at lower speeds and decrease throughput in an attempt to meet difficult quality standards. Meanwhile, more lightweight packaging means more items per ton and more processing per ton, driving up the cost per ton. The increased prevalence of plastics can also lead to fiber bale contamination, causing further obstacles to meeting market specifications.

There are also several concurrent factors encouraging increased residue. As some communities work to increase waste diversion from landfill, implementing pay as you throw (PAYT) and other policies, they may experience an uptick in “wishcycling” and other unintended consequences that increase contamination. Perversely, reduced recycled commodity revenue has impacted recycling program budgets, often undermining the funding for the resident education that is necessary to ensure the quality of inbound materials. On the outbound side, tighter specs mean that marginal-quality material that might once have been baled and sold is now removed and disposed.

When these rising processing costs are stacked up next to the declining average commodity revenue for recyclables coming out of single-stream MRFs, we see a widening gap. Given all the interconnected factors driving costs and markets, this trend may continue before markets improve or policy changes and other interventions show significant effects.

The increase in processing costs as a result of investments and operational changes demonstrates that MRFs are doing their best to adjust to current conditions. And it could all carry a silver lining, with MRF improvements strengthening recycling systems over the long term.

This month’s edition of Data Corner provided by recycling consultancy RRS.

This article appeared in the December 2019 issue of Resource Recycling. Subscribe today for access to all print content.