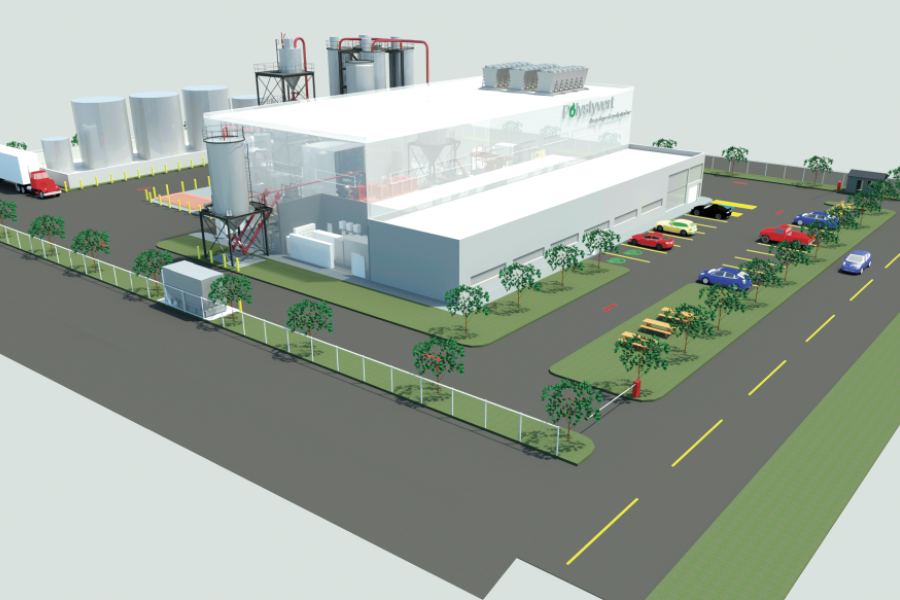

In addition to scaling up its polystyrene recycling capabilities, Polystyvert will collaborate with several partners to adapt its technology to handle ABS. | Courtesy of Polystyvert

Montreal-based Polystyvert plans to build its first full-scale commercial PS recycling plant, as well as a pilot-scale plant for ABS.

The PS plant will have a capacity of 9,000 metric tons of post-consumer and post-industrial PS annually, which amounts to 15% of the PS landfilled in Quebec each year. Polystyvert’s process is able to handle a high degree of contamination, a press release noted.

Polystyvert also has several unnamed partners in the polystyrene industry that will help finance the plant (which has an estimated $30 million price tag USD, converted from CAD on June 21) and ensure both a feedstock supply and offtake of the recycled product.

Nathalie Morin, Polystyvert president, said in the press release that this is a “crucial moment in Polystyvert’s history.”

“After several successful development phases, our technology has reached maturity,” Morin added. “We can now recycle contaminated waste with no other outlet than landfill sites. This plant is the first of many that can be built worldwide by replicating what will be done in Greater Montreal, thereby multiplying the economic and environmental benefits of the project.”

The company’s business model is centered on selling licenses for its proprietary technology, so the commercial-scale plant will act as a showcase for the method. Morin added that she expects “significant interest from key industry players eager to acquire licenses, paving the way for rapid company growth through the cloning of our first full-scale plant.”

Both the commercial-scale and pilot-scale plants will be built in Montreal. The ABS pilot plant will be located at the company’s existing research and development center and will be financially supported by a “renowned global partner,” the press release noted.

The $2.3 million pilot plant is the next step in adapting Polystyvert’s PS recycling technology to handle other plastics, the press release noted.

“Our research and development team has made considerable progress in adapting the technology to a type of plastic that is widely used in numerous applications in our daily lives,” Morin added.