A company with a pilot plant for extracting precious metals from printed circuit boards has filed to become a publicly traded company.

British Columbia-based Modern Mining Technology Corporation, which has a pilot plant in North Carolina, filed a statement with the U.S. Securities and Exchange Commission (SEC) as it looks to scale up its hydrometallurgical recycling process.

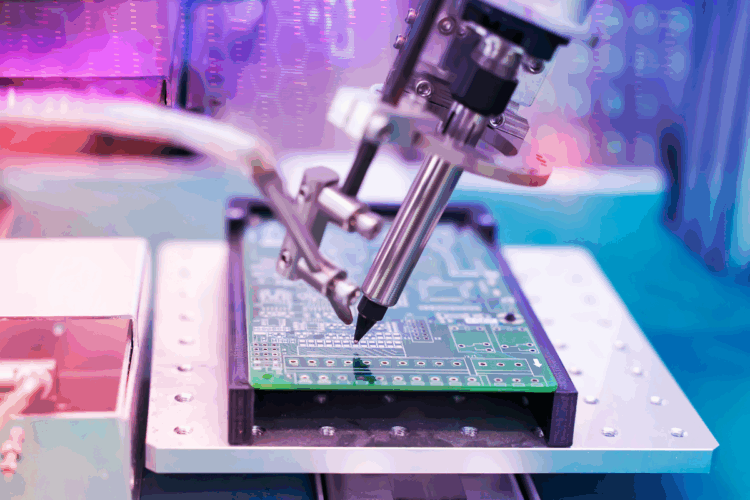

The company uses a pre-concentration plant to remove plastics from the printed circuit board (PCB) scrap to produce a metallic sand concentrate (MSC). The MSC is then sent to an aqueous purification plant, which produces separated gold, silver, copper, platinum and palladium.

“Modern Mining’s process, being aqueous-based, is largely carbon neutral, safer for both workers and for the environment, and allows for the recovery of a broader range of metals as separation and recovery is driven by physical methods and simple reagent addition, not complex pyrometallurgy,” according to the company’s prospectus.

Modern Mining was formerly known as Evotus but changed its name to Urban Mining International in October 2020. In December 2021, the name changed again to Modern Mining Technology Corp.

E-Scrap News wrote about Evotus and its technology in March 2019. Derek Ramsell, the founder and CEO of Evotus, recently told E-Scrap News he sold all of his 68% ownership stake in Evotus to the minority owners of the company in 2020. Ramsell is now CEO of Battery Metals Refining, LLC, a startup focused on extracting metals from lithium-ion batteries.

Efficiency of the recovery process

Headquartered in Vancouver, B.C., Modern Mining currently leases 10,000 square feet in Greenville, N.C. for its pilot and demonstration plant. Kuljit (Jeet) Basi, who has years of experience at several mining companies, serves as president and CEO of the company.

So far, the company has acquired about 12,000 pounds of PCB scrap for commissioning the pre-concentration plant, according to the company’s prospectus.

The pre-concentration plant includes shredding, milling and a water-based separation process to produce the MSC for refining. The separation process recirculates the water.

Since January, the company also installed an e-scrap dismantling station and a depopulation station to remove circuit boards and pre-process them to upgrade the feedstock before it goes to the shredder, the prospectus notes.

Last fall, the company processed about 50 pounds of milled feedstock in the pre-concentration plant’s separation unit, generating about 20 pounds of MSC. The company tested that MSC in December to quantify the metal it contained. Copper recovery ranged from 85% to 98%, and gold and silver testing indicated that recovery of over 90% was achievable.

Since then, Modern Mining has ramped up testing of the pre-concentration plant, sending about 3,300 pounds of milled PCB feedstock through the separation unit to date. The separation unit generated 1,100 pounds of MSC for potential sale.

Of that 1,100 pounds of MSC, the company sent a 650-pound sample to a potential third-party buyer for assaying, and the analysis found it contained 5 ounces of gold, 14 ounces of silver and 450 pounds of copper, according to the latest prospectus, dated July 25.

Looking to raise millions

Modern Mining’s press release notes the company intends to list its shares on the New York Stock Exchange (NYSE). If the NYSE doesn’t approve the listing, however, the company won’t proceed with the offering.

The company noted it intends to offer 2 million shares for sale, with an expected price of around $5.00 per share, generating around $8.57 million after deducting discounts, expenses and commissions associated with the initial public offering.

“Modern Mining intends to use the net proceeds from the offering for research and development expenses, marketing expenditures, capital expenditures, working capital, and general corporate purposes,” the release notes.

According to the prospectus, the company plans to build pre-concentration plants capable of processing about 8,000 metric tons of e-scrap per year. The aqueous purification plants would be sized to handle feedstock generated by four of the pre-concentration plants.

“In the long-term, we intend to secure a larger facility in the Raleigh or Greenville area of North Carolina to serve as our commercial-scale production facility although such future facility has yet to be identified as our current pilot plant facility still has significant capacity that we foresee being adequate in the short-term,” the prospectus notes.