Apple recycled more than 100 million pounds of its devices last year, and it used 10% recycled or renewable materials across its product line. The company released the details in its annual sustainability report.

Recycled-content figures

The Cupertino, Calif.-headquartered electronics manufacturer reported its overall recycled content for 2019. “Based on supplier reports, 10% of the total material we shipped in products in 2019 came from either recycled or renewable sources, one-third of which has been confirmed through third-party certifications,” Apple wrote.

Some products contain substantially more than that figure. For example, the MacBook Air with Retina display, introduced a year ago, contains over 40% recycled content.

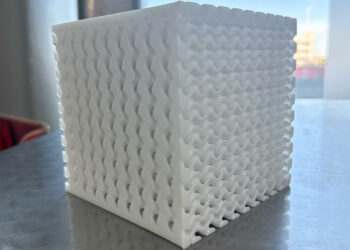

Apple introduced “more than 100 components with an average of 46% recycled plastic across products released in 2019,” according to the report. As one example, the company pointed to its work developing a plastic with more than 35% recycled content that “offers the advanced acoustic properties needed for speakers.”

“We’ve also introduced plastics with the strength and resilience needed for protective cases – made with about 40% recycled content,” the report states.

Rare earth recycling project

The Taptic Engine, which is used in the iPhone 11, iPhone 11 Pro and iPhone 11 Pro Max, is now built from 100% recycled rare earth elements.

That process began with a team from Apple visiting a supplier in China and examining opportunities for greater materials recovery and reuse. A pilot project that targeted rare earth magnets resulted in a scaled-up system of recovering these metals. The company introduced its latest disassembly robot, named “Dave,” which takes apart the Taptic Engine and other components to recover rare earth elements, steel and tungsten.

“While our disassembly robot, Daisy, can take apart iPhone devices into distinct components, our newest disassembly robot, Dave, takes the next step – disassembling the Taptic Engine to recover the rare earth magnets inside,” according to the report.

Apple said it has begun deploying Dave robots so that the company’s “specialty recyclers can recover recycled rare earth elements” and other key materials.

Apple first announced Dave and the Taptic Engine’s recycled content last week.

On a separate rare earth recovery front, Apple said it is working with policymakers to “address restrictions on the movement of electronic waste,” according to the report. The company is interested in enabling movement of end-of-life materials without compromising safeguards that ensure responsible disposal, the report states.

Other takeaways from the report include:

- Lithium-ion batteries recovered by the Daisy robot are providing substantial metals feedstock for the company. For example, this stream has helped Apple secure “a new supply of recycled cobalt for use in future products.” These disassembled iPhones are also generating a significant supply of gold for use in new products.

- The company began using 100% recycled copper in one of the foils of its printed circuit boards, which is being used in the iPhone 11.

- Apple sent more than 11 million devices to be refurbished and sold to new users in 2019. That was a 42% increase over the prior year.

- Apple’s takeback and recycling collection programs, which it participates in or offers in almost all the countries it sells products into, sent 103.6 million pounds of Apple devices to recycling globally in 2019.

- Apple referenced a number of recycling goals in the report. The company described “ambitions” including using only recycled and renewable materials in its products and packaging, as well as eliminating plastics from its packaging by 2025.

- The company is interested in “what the future of recycling could be,” describing technology that “allows recyclers to process high volumes of diverse and increasingly complex electronic waste.” Apple is working with Carnegie Mellon University to apply machine learning to improve recycling technologies. “Researchers are developing methods to train automated systems to sort waste in real-time and learn as they go – so the technology can evolve as waste streams do,” the company wrote. “Any software created from this joint initiative will be open-sourced to help better support e-waste recycling around the world.”