Since the implementation of Chinese scrap import restrictions a number of Chinese companies have set up shop or established partnerships in the U.S. to process material and bypass restrictions. Continue Reading

Since the implementation of Chinese scrap import restrictions a number of Chinese companies have set up shop or established partnerships in the U.S. to process material and bypass restrictions. Continue Reading

Another major importer of recyclables in Asia is drafting policy to reshape its relationship to materials recovery. But this time, the move could actually be a boon to exporters.

Another major importer of recyclables in Asia is drafting policy to reshape its relationship to materials recovery. But this time, the move could actually be a boon to exporters.

A reclaimer and end user will open a $35 million facility in North Carolina, taking in HDPE and mixed-plastic bales for its internal use and for sale as regrind on the market.

A reclaimer and end user will open a $35 million facility in North Carolina, taking in HDPE and mixed-plastic bales for its internal use and for sale as regrind on the market.

Toronto-based GFL Environmental has entered a merger agreement with Raleigh, N.C.-headquartered Waste Industries.

Toronto-based GFL Environmental has entered a merger agreement with Raleigh, N.C.-headquartered Waste Industries.

A major Chinese paper company will add recycled pulp production lines at two U.S. virgin fiber mills it purchased earlier this year, and both will consume mixed paper and OCC.

A major Chinese paper company will add recycled pulp production lines at two U.S. virgin fiber mills it purchased earlier this year, and both will consume mixed paper and OCC.

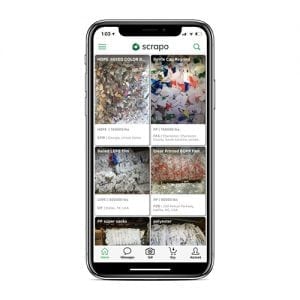

A year after an online scrap plastics trading marketplace launched, an executive at the startup offered insight into where material is moving in the aftermath of China’s ban.

A year after an online scrap plastics trading marketplace launched, an executive at the startup offered insight into where material is moving in the aftermath of China’s ban.

![]()

A major U.S. recycled paper end user will begin accepting fiber bales that contain foodservice packaging at its mills across the country.

An idled Washington newsprint mill will reopen to produce containerboard from recycled feedstock.

An idled Washington newsprint mill will reopen to produce containerboard from recycled feedstock.

OCC prices have remained stable for several months now, bringing some calm to what has been a wildly fluctuating market. But a supply glut may be preventing prices from climbing back up.

OCC prices have remained stable for several months now, bringing some calm to what has been a wildly fluctuating market. But a supply glut may be preventing prices from climbing back up.

Residential fiber values have flattened out, while post-consumer PET prices continue a steady recent climb.

Residential fiber values have flattened out, while post-consumer PET prices continue a steady recent climb.