A project to develop depolymerization catalysts advances with support from a worldwide plastics company, and a bottled water company installs a PET recycling line.

A project to develop depolymerization catalysts advances with support from a worldwide plastics company, and a bottled water company installs a PET recycling line.

A project to develop depolymerization catalysts advances with support from a worldwide plastics company, and a bottled water company installs a PET recycling line.

A project to develop depolymerization catalysts advances with support from a worldwide plastics company, and a bottled water company installs a PET recycling line.

A compounder moves further into the recycled-content space, a recycling machine is literally taken into space and a magazine piece explores black plastic recycling challenges.

A compounder moves further into the recycled-content space, a recycling machine is literally taken into space and a magazine piece explores black plastic recycling challenges.

Recently announced finalists in the FlexPack Recovery Challenge use a variety of recycling technologies – both mechanical and chemical – to recover an often-landfilled material.

Recently announced finalists in the FlexPack Recovery Challenge use a variety of recycling technologies – both mechanical and chemical – to recover an often-landfilled material.

A solvent-based process will be used to recover polymers from multi-layer flexible packaging and fiber-reinforced plastics, and sorting technologies have been installed in New Zealand’s first PET recycling plant.

Starlinger’s post-consumer PET processing lines are coming to a Pennsylvania facility, and an acrylic glass depolymerization project is launched.

Starlinger’s post-consumer PET processing lines are coming to a Pennsylvania facility, and an acrylic glass depolymerization project is launched.

Green Machine has released an optical sorter that incorporates newly patented technology.

Green Machine has released an optical sorter that incorporates newly patented technology.

An Italian company that recycles post-consumer nylon will spend over $40 million to acquire a North Carolina fiber manufacturer.

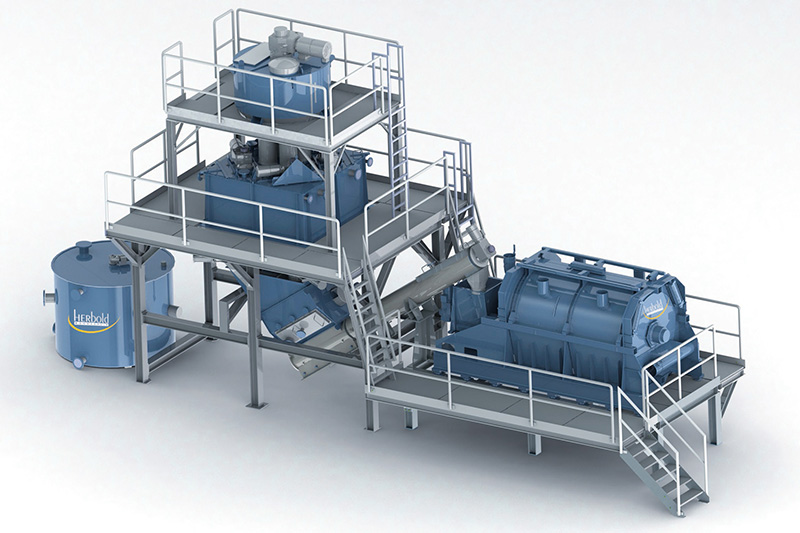

A wash line from equipment supplier Herbold Meckesheim USA cleans a variety of inbound recycled plastic streams as they enter the recycling process.

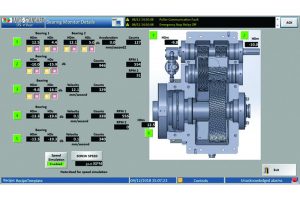

A sample of the Activ-Check screen.

Installing the right equipment is half the battle, but optimizing it for smooth performance is also crucial to success.

Although the recoSTAR line of plastics processing equipment was already available in six sizes, Starlinger added a seventh to meet yet another application last year.

Although the recoSTAR line of plastics processing equipment was already available in six sizes, Starlinger added a seventh to meet yet another application last year.