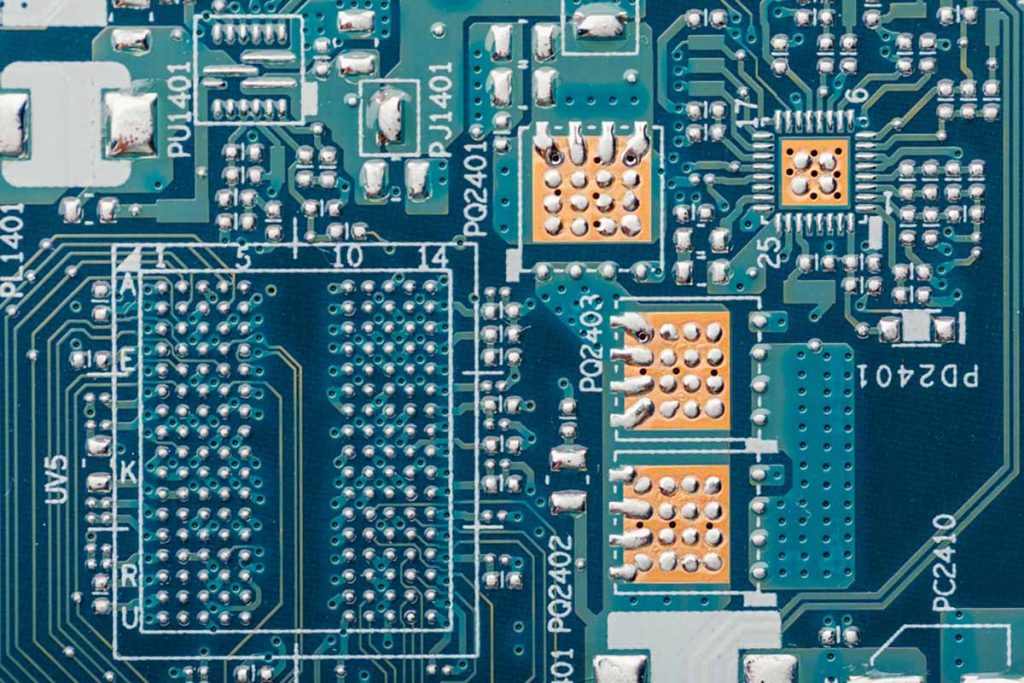

The intensive 12-day course will train professionals in microsoldering and board repair, to help extend device life and ease tariff-inflated electronics costs. | nikkytok/Shutterstock

Although the emphasis on device repairability has risen in recent years, many devices are discarded because of a circuit board failure when they are quite fixable, said Kyle Wiens, CEO of repair firm iFixit.