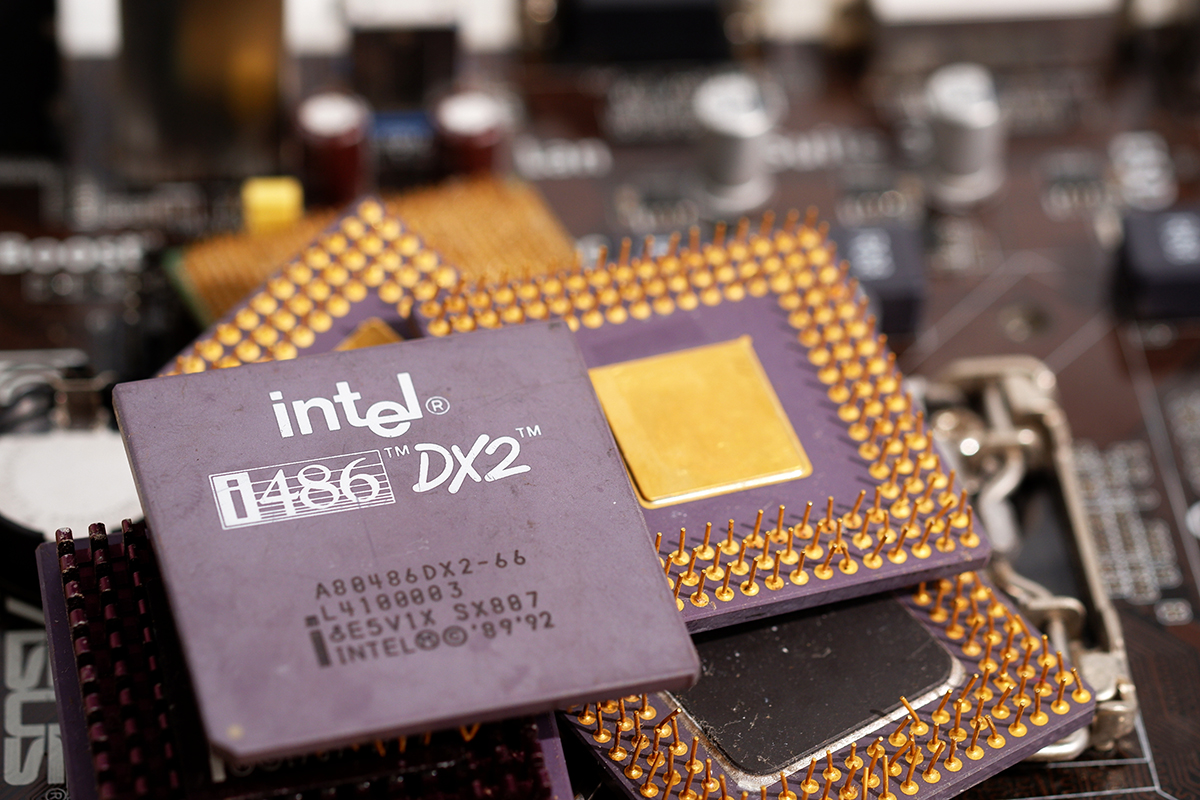

REACT, DOE E-SCRAP finalist from Intel-E-Waste, Sunnking, Penn State and NREL, uses heat- and chemical-free separation to produce high-value e-scrap streams, piloting in 2026. | Damrong Rattanapong / Shutterstock

A project spearheaded by Intel-E-Waste is aiming to reshape US e-scrap recycling by delivering cleaner, higher-value diverse product streams and reducing dependence on overseas smelters.

REACT (Recycling E-Scrap with Adaptive Capacity Technology) is a collaboration between Intel-E-Waste, Sunnking Sustainable Solutions, Pennsylvania State University and the National Renewable Energy Laboratory (NREL). The project was a finalist in the 2025 US Department of Energy E-SCRAP Prize, which earned the State College-based operation $50,000 in funding.

Mohammad Rezaee, associate professor of energy and mineral engineering at Penn State University, said REACT is low-cost, doesn’t use heat or chemicals, and is designed to match specific feedstock characteristics, throughput and product quality requirements of electronics recycling.

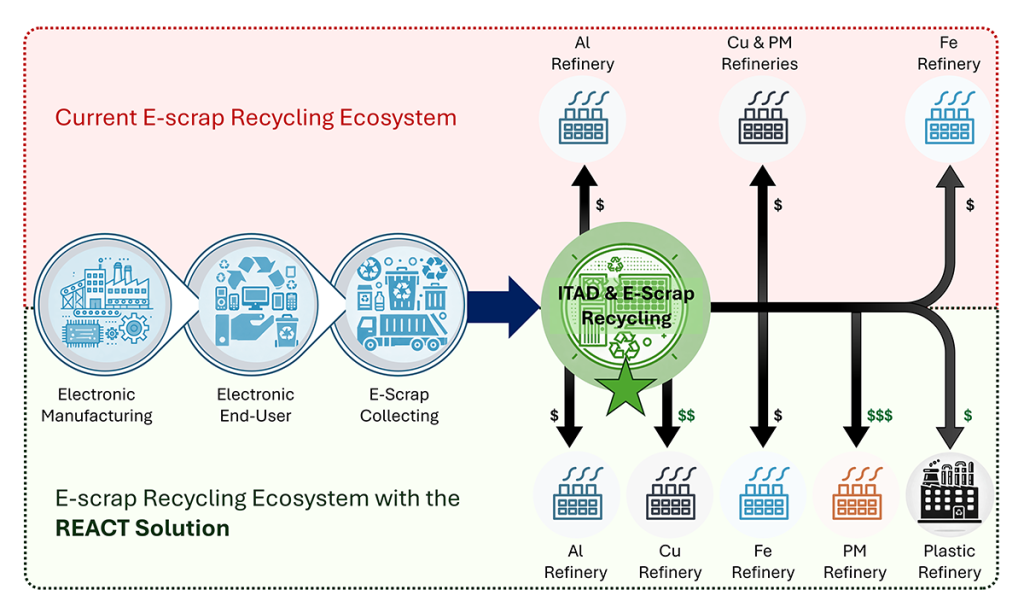

“By leveraging differences in mechanical and physical properties of materials, REACT selectively liberates and separates components into high-value product streams,” he told E-Scrap News. Unlike conventional e-scrap recycling, which primarily targets bulk ferrous and non-ferrous metals, REACT maximizes the recovery and grade of critical materials, including aluminum, copper and precious metals, while also recycling plastics, he added.

The technology also processes a wide range of particle sizes, including the often-overlooked under-10 mm precious metal–rich fraction, to help minimize material losses.

“This adaptive capacity makes REACT both a competitive and complementary solution to conventional methods,” Rezaee said. “It not only aligns with international regulations such as the Basel Convention but also diversifies and upgrades the value streams available to recyclers, strengthening revenue potential while reducing environmental impacts.”

Penn State drives the research and development of the REACT technology. Under Rezaee’s direction, the university provides expertise in mineral processing and recycling, supported by advanced laboratory and pilot facilities.

Sunnking Sustainable Solutions has been a major asset by supplying real-world feedstock, process data, operational expertise and continuous feedback on economics and logistics, Rezaee said.

Intel-E-Waste oversees process design, scale-up and commercialization planning. Engagement with NREL further strengthens the project by providing technoeconomic analysis and life-cycle assessment for data-driven optimization, economic viability and sustainability.

“Together, these roles bridge innovation with practical deployment, ensuring REACT is both scientifically sound and commercially viable,” Rezaee said.

Courtesy REACT

REACT was first developed for recovering critical materials from discarded printed circuit boards and was expanded and validated for broader e-scrap in collaboration with industry partners during Phase I of the E-SCRAP Prize.

One challenge for the project is the variability of e-scrap feedstocks, which requires consistent delivery of high recovery and grade across very different material streams. Penn State researchers are addressing this by refining adaptive process controls and validating performance with diverse feedstock provided by industry partners.

“Another challenge lies in logistics, since collection and transport of e-scrap remain fragmented across the US, making it essential to design REACT as a modular system that can integrate directly into existing facilities with minimal disruption,” Rezaee said. “On the regulatory side, landfill policies vary widely—nearly half of US states do not regulate the landfilling of end-of-life electronics. Our goal is to make REACT cost-competitive with landfill disposal so that recyclers have a viable economic alternative.”

“We have demonstrated consistent separation of metals, plastics, glass and critical materials at high recovery and grade levels,” Rezaee said. The project partners now are preparing for prototyping and pilot-scale demonstrations with industry partners to move toward commercial deployment.

“Our immediate goal is to build and demonstrate a prototype system through integration at Sunnking Sustainable Solutions and other partner facilities,” Rezaee said. “These demonstrations will allow us to refine process efficiency, validate recovery and grade of the product streams, confirm technoeconomic and life-cycle analysis and prove cost competitiveness at pilot scale.”

Following that phase, the team would scale up REACT into a turnkey recycling line that recyclers can adopt with minimal retrofit.

The team expects REACT to be ready for early integration by the end of 2026. In the near term, its prototypes will be demonstrated at partner facilities to validate efficiency, cost competitiveness and operational fit.

“Because REACT is heat- and chemical-free, it is designed to slot into existing recycling facilities with minimal permitting requirements,” Rezaee said. “This accelerates the path to adoption compared to conventional technologies. With support from industry partners and the DOE E-SCRAP Prize program, our goal is to make turnkey REACT modules commercially available in the next phase of development, positioning recyclers to respond quickly to the growing volumes of e-waste.”