As the latest generation of laptops reaches the desks of students and professionals, a closer look beneath the surface reveals a tension between sustainability aspirations and end‑of‑life reality.

A new study from my firm, Compliance Standards, entitled “Sustainability, Serviceability and Scrap: A Technical Review of 2025 Back‑to‑School Laptops” provides detailed appraisals of circular design performance in current models. The analysis covers flagship releases from major original equipment manufacturers (OEMs) including Dell, HP, Lenovo, ASUS, Acer and Apple, which together represent the majority of global shipments in the portable PC sector.

Performance over practicality

The report finds that while manufacturers have expanded their use of recycled content, low‑carbon aluminum and sustainable packaging, progress toward disassemblable, component‑friendly designs remains limited. Adhesive‑bonded batteries, laminated screens and closed chassis construction are still widely used across most brands.

Roughly one‑third of the laptops reviewed are projected to maintain meaningful refurbishment value by the time they enter IT asset disposition (ITAD) streams later this decade.

Enterprise‑grade systems generally scored higher, retaining limited modularity through accessible storage or wireless components. By contrast, consumer ultrathin models – while energy efficient and marketed as “eco‑conscious” – often produce scrap‑heavy outcomes once they reach recyclers.

Regulatory and market shifts

From a regulatory standpoint, policy changes are accelerating the accountability trend. Within the European Union, updates to Ecodesign and waste electrical and electronic equipment frameworks are expanding circularity requirements, setting measurable criteria for recyclability and critical‑material recovery. At the same time, US states are enacting right‑to‑repair laws aimed at service accessibility and design transparency.

While these regulatory pressures are encouraging incremental improvements, the design reality remains mixed. Many 2025 devices incorporate recycled metals and bio‑based finishes, but internal construction decisions – soldered memory, layered adhesives and fully sealed enclosures – still limit recoverability. Circularity progress, in short, tends to appear more convincing in sustainability reports than in teardown results.

The report notes that extended producer responsibility (EPR) programs emerging in Latin America and Asia will further shift downstream economics by compelling OEMs to finance end‑of‑life processing. For independent recyclers and ITAD firms, this environment rewards those who can act as EPR‑aligned solution partners, offering compliance data, traceability, and transparent recovery reporting to manufacturer clients.

Implications for ITAD and recycling operations

Compliance Standards classifies the 2025 cohort into three circularity groups: refurbishment‑heavy, mixed‑value and scrap‑heavy. Most consumer and education‑oriented systems fall into the latter category, signaling higher material throughput but weaker resale potential.

For ITAD and electronics recycling operators, the operational impact could be significant. Adhesive‑sealed lithium‑ion batteries elevate both insurance and safety costs, while laminated organic light-emitting diode (OLED) displays require either specialized tooling or robotic handling to prevent breakage. The report notes that battery‑safe automation and containment systems will soon represent standard operational requirements rather than optional investments.

From a business perspective, ITAD profitability will increasingly rely on bifurcated workflows – targeted refurbishment for enterprise‑grade equipment maintaining resale value and cost‑optimized material recovery for compact consumer hardware.

This shift redefines where competitive advantage lies. High‑value remarketing alone will not sustain margins. ITAD firms will need to expand vertically – investing in pre‑processing automation, fire‑safe robotics and sustainability‑compliant certification frameworks that align with tightening customer audit standards.

The study also highlights implications for recyclers and material recovery operators. Between 2029 and 2030, incoming ITAD and e‑waste streams from these devices are expected to tilt toward plastic‑heavy, low‑value units and adhesive‑rich premium aluminum systems.

For recyclers, that means increasing cost per ton processed, unless automation offsets labor intensity. Plastic housings from education‑class systems, often containing brominated additives, will depress yield, while OLED and laminated displays will generate fragile waste streams unsuitable for standard shredding. The report recommends that recyclers develop OLED‑safe dismantling systems to minimize loss from screen breakage, upgrade battery recovery infrastructure with temperature‑controlled pre‑processing zones and increase collaboration with ITAD partners to standardize data wipes and component grading before material extraction.

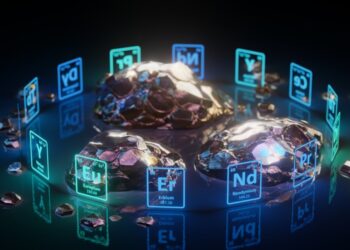

For urban mining enterprises, these shifts signal a parallel opportunity. Scrap‑heavy devices still contain recoverable critical elements, including aluminum alloys, high‑density interconnect boards, copper wiring and trace rare‑earth materials. By deploying low‑temperature separation and hydrometallurgical recovery, urban miners can reclaim value that would otherwise remain locked in bonded assemblies. Strategic alignment between ITAD firms and recovery facilities through shared logistics or joint processing ventures will convert non‑refurbishable inventory into traceable, high‑purity feedstock streams, supporting both revenue and corporate circularity reporting.

Outlook

For e‑scrap professionals, recyclability should not be viewed merely as an environmental metric, it is now a central cost and risk driver. Labor time, safety controls and part accessibility are determining factors for profitability across ITAD and recycling operations.

The 2025 laptop generation shows technical progress, but structural inertia. Enterprise‑segment vendors have proven that modularity and performance can coexist, yet consumer‑grade architectures remain difficult to process and value at scale.

As AI‑optimized and hybrid devices define the next refresh cycle, recognizing these physical design realities in advance will be critical for market positioning. The report concludes that ITAD, recycling and urban mining firms able to merge automation, compliance assurance and downstream recoverability into unified service models will be best positioned to compete in the circular economy’s next phase where value is measured by verifiable recovery performance and material yields.