The acquisition of Retronix will help global electronics manufacturer Jabil enable reuse of electronic components that may otherwise face the shredder.

Jabil, a manufacturing giant based in St. Petersburg, Fla., acquired re-balling specialist Retronix in March. Financial terms were not disclosed for the acquisition, which was announced in a November press release.

“Like Jabil, Retronix works with leading brands across industries such as telecommunications, defense, automotive, and healthcare,” Jed Pecchioli, vice president of supply chain at Jabil, stated in the release. “Now, these services will be available to Jabil customers, and together, we will strengthen the circular economy.”

Pecchioli, who is now overseeing Retronix, told E-Scrap News in an interview that the acquisition represents an early and significant step into reuse and recycling for Jabil.

“There’s so much opportunity for everybody: customers, suppliers, the environment,” he said.

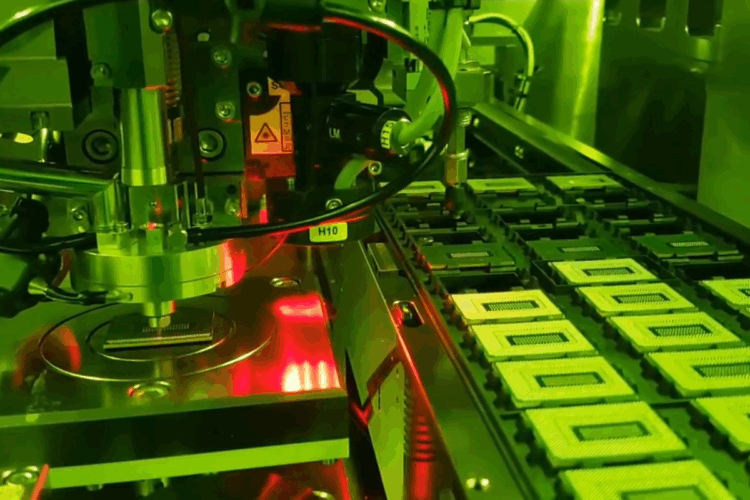

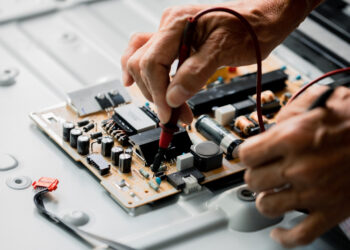

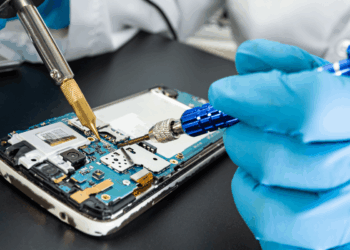

Founded 30 years ago, Retronix specializes in re-balling and re-tinning services, which is essentially removing and replacing solder that holds surface-mounted components on a printed circuit board (PCB). With facilities near Austin, Texas and Glasgow, Scotland, the company’s services include removing tin balls and replacing them with lead balls in instances where lead is required because of the environment the circuit boards operate in. That’s particularly the case in medical, military and aerospace applications, Pecchioli said.

The intricate work also allows used components – including those no longer in regular production – to be removed from obsolete or faulty boards and reused or resold.

Retronix also provides component authenticity testing services, Pecchioli noted; in fact, Jabil first started working with Retronix on authenticity testing. Now, the emphasis is on the circular economy, he said.

“I think the part reclamation and the thing we can do with that in multiple avenues is a pretty cool and exciting thing we’re facing,” he said.

Demand for Retronix’s service was ramped up by the pandemic. Jabil’s customers struggled to get the newly manufactured parts they needed for production, repair or other services, he noted. Meanwhile, those same customers had “boneyards” where reusable parts on top of bad PCBs were languishing in storage. Retronix recovers those parts for the customers.

Additionally, Retronix recovers parts for resale, getting value back for the customer and enabling reuse.

Jabil is currently putting best practices in place at Retronix, with a focus on Retronix’s core businesses, Pecchioli said. Going forward, Jabil will look to scale up its Retronix operations.