The first full-scale rare earth magnet recycling facility in the U.K. will be based in Birmingham, England, following work by University of Birmingham researchers.

According to a press release, rare earth magnet recycling company HyProMag, formed by researchers from the University of Birmingham’s School of Metallurgy and Materials, is developing the first full-scale remanufacturing facility for rare earth magnets in the U.K.

The push forward comes after the company was acquired by Maginito, a green technology development and investment company. The acquisition allows for a commercial-scale operation, the press release noted.

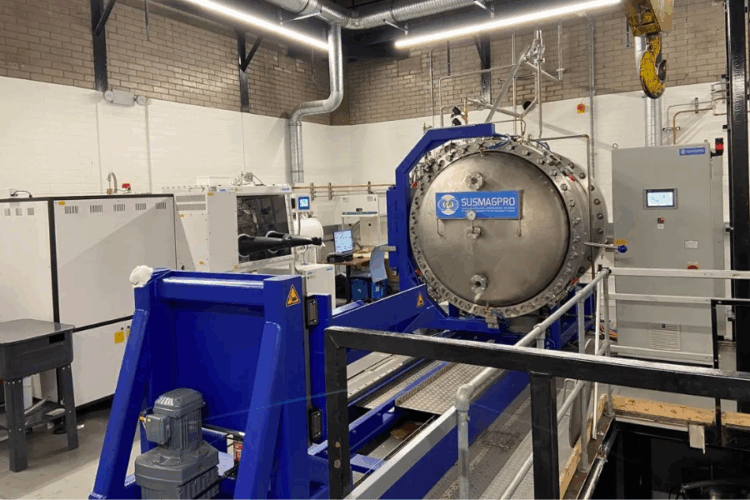

Technology at the facility will employ a patented process called hydrogen processing of magnet scrap (HPMS) to extract rare earth magnets from scrap material and redundant equipment, processing them into a demagnetized powder and then remanufacturing it. A pilot plant for this technology has been running at the University of Birmingham since last year.

The upcoming $5.3 million facility is being developed alongside the University of Birmingham and funded by Driving the Electric Revolution, a U.K. Research and Innovation fund.

The commercial-scale facility is expected to have a minimum production capacity of 100 metric tons per year. First production is slated for later this year.

A Maginito press release noted plans to also build facilities in Germany in 2024 and the U.S. at some point in the near future.

Allan Walton, head of the Magnetic Materials Group at the university and co-founder of HyProMag, said in the press release that Maginito has been a strategic partner for the university and HyProMag since the company started in 2018.

“The companies have a shared vision to create a large-scale, international business focused on downstream rare earth technologies, with major competitive advantages in the rare earth recycling sector, including the patented energy-efficient technology for recycling magnet scrap,” the press release noted.