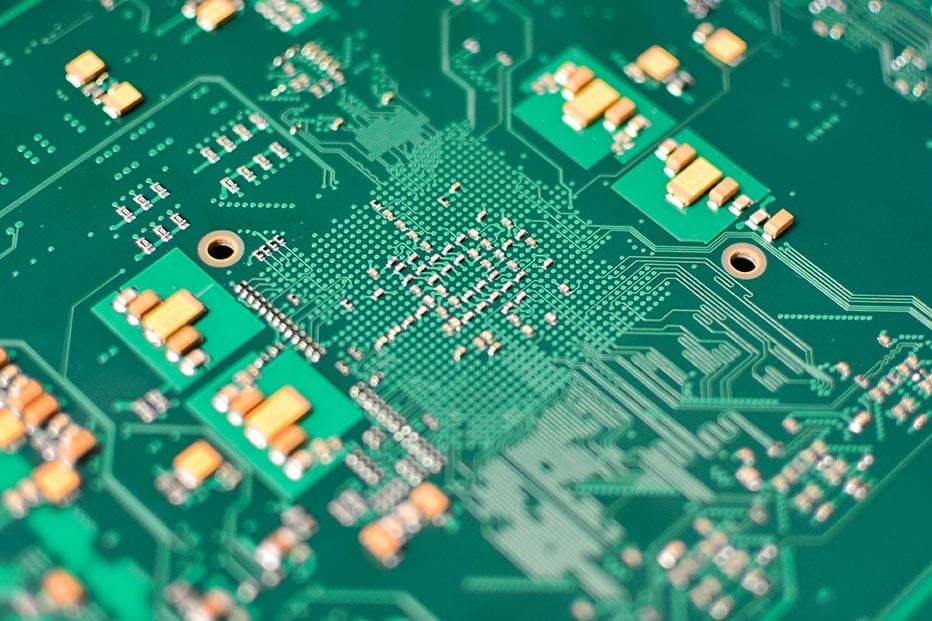

A number of research projects looking into metal recovery from circuit boards received funding recently. | Borhax/Shutterstock

Research focused on recovering precious metals from printed circuit boards received funding from the REMADE Institute. Meanwhile, the organization will provide up to $35 million for its next round of grants.

Based at the Rochester Institute of Technology (RIT) in New York, the REMADE (Reducing Embodied-Energy and Decreasing Emissions) Institute is a public-private initiative that funds research into remanufacturing and recycling technologies.

Third funding round awards

Launched in early 2017 and supported by federal funds, the institute has now awarded funding in three rounds. The first round of funding was announced in July 2018, and the second round recipients were unveiled in May 2019.

The third round, announced Aug. 17, touches on designing equipment for recovery, reuse, remanufacturing and recycling (referred to in the release as “Re-X”); developing improved technologies for recovering metals from scrap electronics; improving scrap plastic sorters; boosting recycled fiber quality; and training the workforce in paper recycling.

The e-scrap-related projects that were “selected for negotiations” for funding involve methods of recovering valuable metals from printed circuit boards (PCBs), according to the release.

One project, titled “Low-Concentration Metal Recovery from Complex Streams Using Gas-Assisted Microflow Solvent Extraction (GAME),” is led by Virginia Tech and Phinix LLC. The effort focuses on developing an efficient and cost-effective method of extracting and purifying precious metals PCBs.

Separately, Penn State University and CHZ Technologies are researching a project titled “Development and Validation of Metal Separation Technology for Complex Metal Systems,” which similarly focuses on developing an efficient, low-cost and environmentally harmless leaching method for extracting metals from PCBs.

$35M available for awards

In a separate Aug. 17 press release, the REMADE Institute announced it has issued its fourth request for proposals to invest up to $35 million in R&D projects focused on metals, polymers, fiber and e-scrap. The funding must be matched dollar-for-dollar by project participants.

For its fourth round of funding, REMADE has prioritized domestic recycling of plastics, according to the release.

Letters of intent and project abstracts are due at 5 p.m. Eastern time on Sept. 14, with full proposals due by 5 p.m. Eastern time on Oct. 19.

“With the challenges facing industry today, it is increasingly important to improve U.S. manufacturing competitiveness,” stated Nabil Nasr, CEO of REMADE, in the release. “Our partnership of 100 industry, national laboratory and academic innovators are working together to reduce the energy and environmental burden of domestic manufacturing while delivering value to industry, the economy and the environment.”

A version of this story appeared in Plastics Recycling Update on August 26.

More stories about research

- Project brings rare earth recovery into e-scrap facility

- Texas A&M researches rare earth extraction

- Report: Battery ‘retirement tide’ nears