Recycled-content laws are a tool for driving post-consumer resin demand. But what if producers are given too many outs, feedstock is in short supply, or the mandates actually result in greater environmental harm?

Those were concerns raised by three recycling industry experts during a Jan. 6 webinar focused on recycled-content mandates, which are laws and regulations requiring packaging makers and others to use a minimum amount of recycled material in their products.

Recycled-contents requirements were the central topic of bills signed into law in California and Washington state. Now, New Jersey’s governor has signed aggressive minimum-recycled-content legislation into law. They’ve been proposed at the federal level, as well.

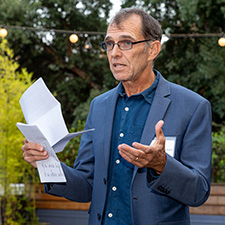

Mark Murray of Californians Against Waste, Steve Alexander of the Association of Plastic Recyclers (APR) and David Allaway of the Oregon Department of Environmental Quality presented during the webinar, which was hosted by the Northeast Recycling Council (NERC), the Northeast Waste Management Officials’ Association (NEWMOA) and the West Coast Climate and Materials Management Forum.

The webinar drew 622 viewers, according to NERC.

Past experience in California

Mark Murray, the executive director of the advocacy group Californians Against Waste (CAW), explained how failed past policies can help inform the new legislative push for recycled-content mandates.

He pointed to the Golden State’s three-decades-old rigid plastic packaging container law, which exempts some key categories, including containers for food, drugs, cosmetics, baby formula and medical devices. The policy gives manufacturers too many options for compliance, he said, and “at this point contributes zero to recycling market development, recycling funding and producer responsibility.”

For example, under the specifics of the policy, instead of incorporating 25% recycled content in containers, manufacturers can reduce the container weight by 10%, concentrate the product by 10%, or show that the container is 10% lighter than comparable competitors’ products.

“Mostly folks talk about their source reduction and we’re done with it,” he said.

Adding to the issue, Murray said, is the fact that sufficient funding for enforcement hasn’t been provided.

California’s other recycled-content laws requiring recycled plastic be used in trash bags and recycled glass be used in glass bottles and fiberglass insulation also fail to drive increases in the value of recycled materials, he said. The minimums were set at what was reasonable to achieve, but the levels haven’t moved the marketplace or increased the value of the recycled material, Murray pointed out.

In the case of glass products, state law requires bottles to have at least 35% recycled content and insulation to use at least 30% recycled content. According to the California Department of Resources Recycling and Recovery (CalRecycle) 2020 glass report, bottle producers averaged 42.6% and insulation producers averaged 47.7%.

Year after year, the reports show producers are meeting the requirements, Murray said, but the amount of recycled glass being used is less than what’s collected, and the program isn’t driving cullet prices higher. The curbside recycling programs continue to have to pay to send glass from materials recovery facilities to an intermediate processor that will sort and clean up the material, he said.

“Other than the nice-looking reports that we get every year, [the requirements are] not doing anything to enhance the market for recycled glass,” he said.

All that being said, he’s optimistic about the latest recycled-content requirements passed in California. Assembly Bill 793 makes brands solely responsible for achieving 50% post-consumer resin (PCR) in beverage containers by 2030. Producers will pay a penalty of 20 cents for each pound they fall short of the target.

“The idea behind this is more than just creating markets for recycled material,” he said. “It is ultimately making manufacturers partners in ensuring that they have sufficient material to meet this requirement.”

Murray added that increasing public and policymaker support for product bans is putting beverage brands in the hot seat: “My message to the beverage industry is, ‘I think you’re in a recycle-or-die moment.'”

Mandates can drive negative environmental outcomes

David Allaway, senior policy analyst at the Oregon Department of Environmental Quality (DEQ), offered a different take on recycled-content mandates, arguing that they aren’t always the right tool for the job.

They don’t necessarily support local supply of recycled material, he said. For example, if Vermont imposed a recycled-content requirement on glass wine bottles, then it may boost glass recycling efforts on the West Coast, where bottles are made and filled, but not locally.

Another concern is the mandates simply “cannibalize” existing markets using the recycled materials. DEQ studied multiple management pathways for recycled glass cullet: landfilling, bottles, fiberglass, aggregate and pozzolan, which is a fine material used in concrete. The recycling industry has a strong bias toward closed-loop recycling, he noted, or recycling the cullet back into bottles.

But in terms of global warming contribution, grinding glass into a fine powder as using it as pozzolan had, by far, the least impact, according to his presentation. Using cullet in bottles and fiberglass displaces silica, but pozzolan reduces cement production, which produces substantial greenhouse gas emissions, he said. Additionally, no heating is required to melt the cullet when it’s used in pozzolan.

Yet if policymakers mandate recycled-content in glass bottles, it could hamper growth in the nascent pozzolan industry.

“Mandating [post-consumer] content in glass bottles could actually have a perverse outcome,” Allaway said.

The same could be true in plastics, he said. For example, recycling HDPE packaging into packaging or pipes offsets the need for virgin HDPE in both cases. But more costs and environmental impacts are incurred when processing scrap for use in packaging, according to his presentation.

He cited a 2015 Journal of Industrial Ecology study, “Common Misconceptions about Recycling,” that argued the preference for “closed-loop” recycling over “open-loop” recycling should be discarded in favor of choosing whichever end use has the highest virgin resources displacement potential.

Allaway also noted that using PCR doesn’t always mean offsetting an equivalent amount of virgin resin. Because of differences in engineering qualities, some products may require more plastic be used if its PRC rather than virgin plastic. In those cases, the greater materials erodes the environmental benefits of recycled resin usage.

Shifting focus to supply is crucial

Steve Alexander, president and CEO of APR, noted that his group was the first industry association to support recycled-content legislation, back in 2006. Starting this year, however, he sees APR putting greater focus on supply.

“We need to ensure that we’re collecting enough material to meet these mandates,” he said. (APR owns Resource Recycling, Inc., publisher of Plastics Recycling Update.)

To enable circularity, the first thing that must happen is a product or container must be designed to be recycled, he said, noting that APR’s Design Guide is the most referenced authority globally for companies looking to develop recyclable products.

Additionally, more material needs to be captured. Alexander cited data showing that, in robust recycling programs, households average 77 pounds of PET annually, but less than one-third of that makes it into the recycling stream. Contributing to that gap is consumer confusion, driven by poor product labeling and inconsistent “accepted recyclables” lists.

“We do a wonderful job – all of us – in confusing the consumer,” he said.

APR has been working with the Federal Trade Commission to help inform its update to the Green Guides, which cover environmental sustainability-related marketing claims on products, including recyclability, and were last updated in 2012. The guides could be updated to eliminate confusion in the marketplace, Alexander said, but APR is concerned they may end up lacking specificity.

In terms of demand, APR launched a PCR Certification program to provide certainty to brand owners that the PCR they’re buying is, in fact, post-consumer material, not post-industrial, he said. APR has also worked hard to support expanded uses for PCR beyond the original products. For example, Waste Management began buying curbside carts made with 10% recycled content, creating a huge market demand for recycled polyethylene.

Crates, slip sheets and pallets are other products that are made of recycled plastic, he noted. One manufacturing facility, alone, created demand for 2.5 million pounds of recycled plastic per year when it transitioned from wooden pallets to plastic ones, he said.

A version of this story appeared in Plastics Recycling Update on January 12.