One of the world’s largest packaging producers boosted its purchases of post-consumer resin by about 30% last year.

Switzerland-headquartered Amcor purchased 104,523 metric tons of post-consumer resin (PCR) during its 2021 fiscal year, up 86% from the 2019 fiscal year and 30% from the 2020 fiscal year, according to the company’s recently released sustainability report.

In other Amcor news, the company announced it is redesigning small plastic bottles so they can be more effectively sorted into the correct bales at materials recovery facilities (MRFs).

PCR details

The 104,523 metric tons of PCR used last year was 4.2% of the total resin purchased by Amcor, the report notes. It accounted for 3.2% of total feedstock purchased by the company. Much of the plastic packaging produced by the company is PET bottles, although it produces other containers and a significant amount of flexible packaging.

The company, which has signed on to the Ellen MacArthur Foundation’s Global Commitment, has a target of using 10% recycled resin across its portfolio by 2025. The foundation recently released its third progress report for the Global Commitment, including details on PCR use by Amcor and other signatories.

“We continue to work with our current suppliers to source more recycled materials, and to seek out new suppliers who can help support our ambition to use more,” according to the sustainability report.

Bottles that crush predictably

Amcor has developed a small bottle that can be better sorted at MRFs, according to a company press release.

Early on in the sorting process, MRFs use screens to remove small items from the stream, often for disposal. The problem is small PET bottles – 50 milliliter liquor bottles known as “nips,” “shooters” or “airplane bottles” – will fall through the screens alongside broken glass and other small items, and they’ll never make it into a PET bale.

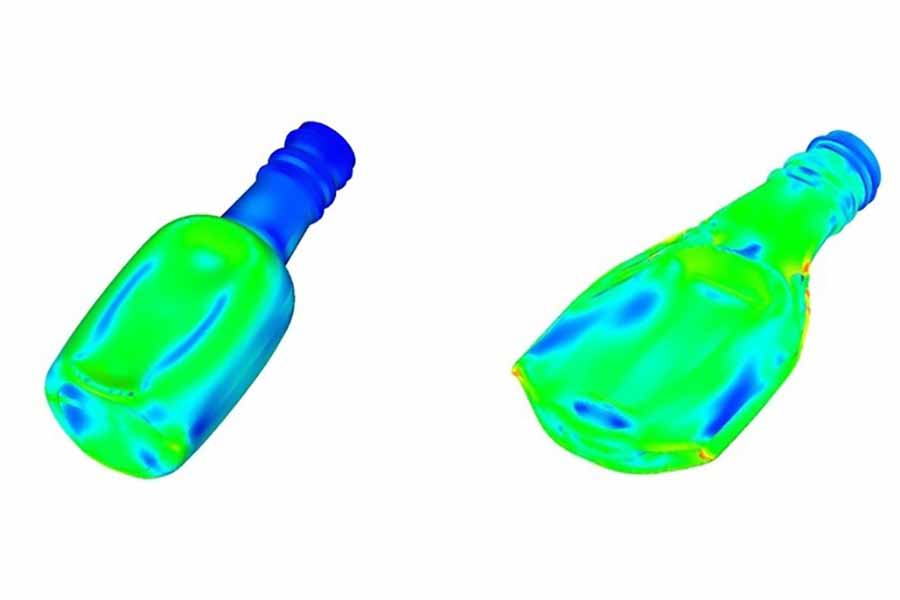

Amcor redesigned the small bottles with predictable failure points so that when they’re compacted in a recycling collection truck, they’ll collapse to larger than five centimeters wide. That will help them pass over the gaps in most MRF screens, giving later sorting equipment the opportunity to separate them into a PET bunker.

“Our simulations demonstrated that when these tiny spirits bottles are designed to collapse in a specific way, fewer bottles actually fall through the cracks,” Terry Patcheak, vice president of Research & Development and Advanced Engineering at Amcor Rigid Plastics, stated in the release. “The potential here is higher recyclability rates and more recycled content for multiple segments and materials.”

Amcor plans to conduct further testing on how the bottles perform under real-world MRF conditions.

“At a time when the recycling industry is constrained by material supply, every additional pound diverted from waste makes a big difference,” Curt Cozart of the Association of Plastic Recyclers (APR) stated in the release. (APR owns Resource Recycling, Inc., publisher of Plastics Recycling Update.)