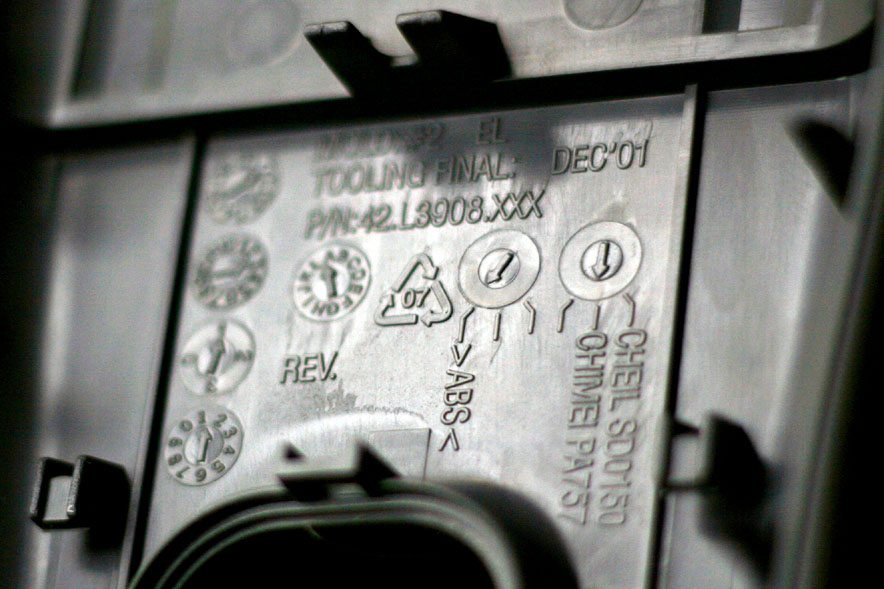

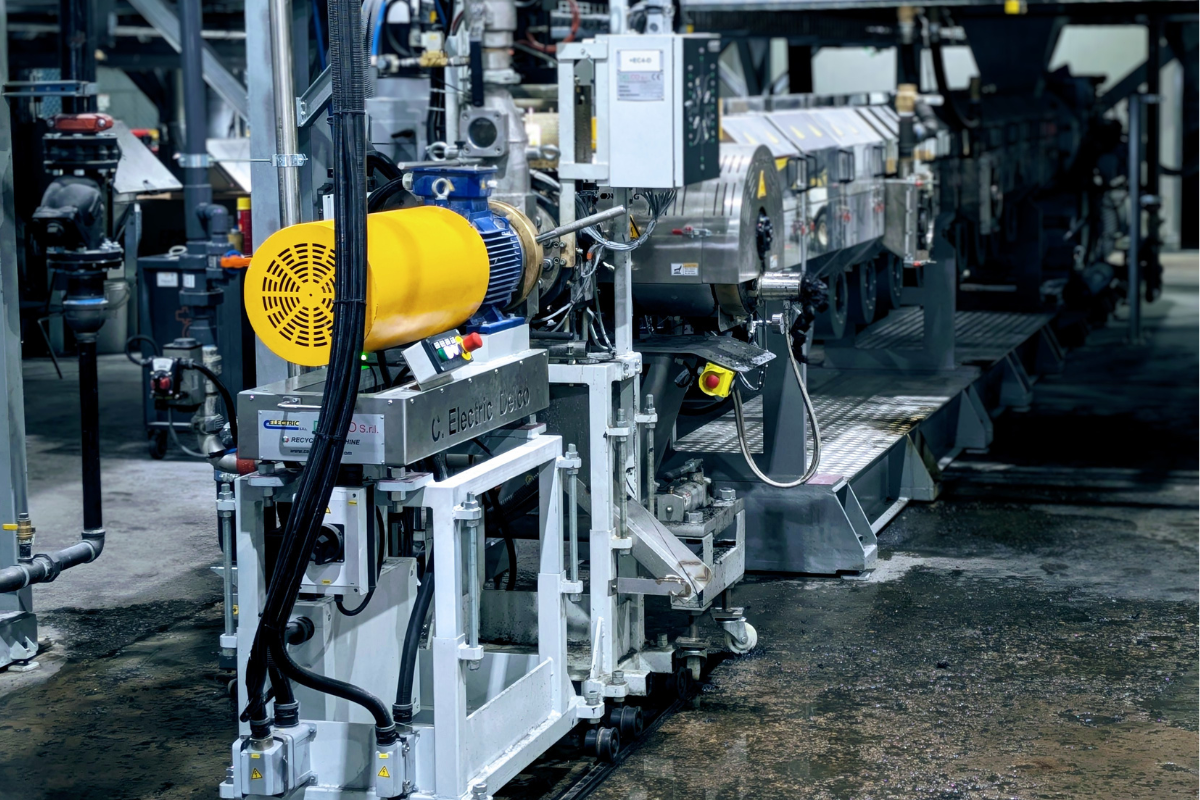

Dissolution recycling processes can provide effective separation of flame retardants, metals and more from e-plastics. | Damrong Rattanapong/Shutterstock

Industry association Plastics Recyclers Europe is looking to raise the profile of dissolution recycling, an often-overlooked process that doesn’t quite fit into common recycling categories and is capable of processing a wide variety of hard-to-recycle materials including e-plastics.