A Texas company that started out in oil and gas drill bit reclamation has now diversified into recovering e–scrap and other industrial material streams, and it’s adding facilities to house the growth.

Ryan McAdams, CEO of Austin, Texas-headquartered Amermin, said everything started a decade ago in his garage as he experimented with separating different alloys and metals from each other using electric currents.

“We were in oil and gas drill bit reclamation, and we started to slowly figure out what’s recyclable of these other materials,” he said. As he kept tinkering with different metals and separation methods, “that started the snowball, and the black hole of my interest kept growing.”

McAdams decided to start a new company focused on recycling and sending zero materials to landfill, and kept building from there. Aerospace material, largely production scrap, is now the fastest growing material sector, he said, and the company is also recovering construction and demolition debris. Batteries are also in the equation.

“It started really growing in the last two years, and diversifying,” McAdams said. “We’d love to get more into battery recycling. It seems like it’s getting pretty competitive right now, but there’s so much out there it will never stop coming in.”

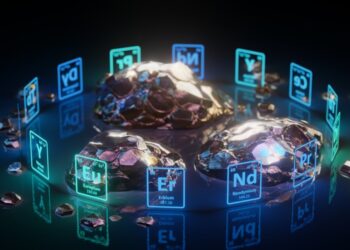

The company largely targets materials with tungsten in them, but will also recover cobalt, nickel, and copper from all kinds of electronics, and graphite from batteries.

Those diversified streams help the company maintain its zero waste to landfill policy, McAdams said, because “even if it’s extraordinarily difficult or we don’t even profit from doing anything with it, we’ll still find a home for it or find someone who can specialize in that specific waste stream.”

To date, Amermin has recycled 45 million pounds of material, which produced 15 million pounds of tungsten. About 1.5 million pounds of that tungsten was recycled in 2023 alone, and the company is projecting it will recycle an additional 3 million pounds of tungsten in 2024.

To keep up with that growth, Amermin is looking to add to its three current facilities. There’s a staging and sorting facility in Fort Worth, Texas, a main processing facility in Lampasas, Texas, and another intake facility in Del Valle, near the Austin airport.

In addition to those, the company owns 75 acres of land in Briggs, Texas, that McAdams plans to turn into a main recycling compound. He hopes to have the first two 22,000-square-foot buildings up by next year, then add up to eight more buildings of a similar size over the next decade, depending on what materials Amermin starts taking in and what is needed.

“Seventy-five acres is a lot of land, and the 10 buildings will not take up all of that, but in terms of material storage and everything coming in, it’s got to have a place to sit,” McAdams said.

He’s confident about the growth of the aerospace portion of the business in particular, he said, because “when people really start to notice how much money can be saved you really start to change people’s mentality.”

McAdam’s favorite part of the job is doing a site visit and pointing out to a company’s operations team and procurement team just how many things that are going to landfill could be diverted, saving money and resources.

“I’d love to come treasure hunting at your facility,” he said.