Editor’s Note: The MRF Best Practices Guide will be featured in a session at the 2026 Resource Recycling Conference, Feb. 23-25 in San Diego, California. Register now for the best rates.

As a linchpin of the recycling system, MRFs in the US are heavily impacted by macro shifts in the economic and policy landscapes.

Changes in consumer purchasing, commodity pricing and state and federal policies ultimately impact the types and volumes of materials that flow into recycling facilities, and the demand for the recycled commodities produced.

Now with the accelerating implementation of extended producer responsibility (EPR) policies and evolving recycled content commitments by consumer packaged goods companies, the landscape is shifting at a more rapid pace.

To support MRF operators in this dynamic environment, transparency, performance-based metrics, and targeted education and funds are more important than ever to maintain optimal operations and material recovery.

While some recycling facilities already have best-in-class operating standards, there has not been an industry-wide standard for MRF best practices, until now.

Closed Loop Partners’ Center for the Circular Economy, in collaboration with American Beverage and with support from Resource Recycling Systems (RRS), published a first-of-its-kind MRF Best Practices Guide.

The new guide equips MRFs with actionable tactics to optimize recovery rates, increase material quality, maximize throughput, extend equipment life and foster resilient, high-performing teams.

What US MRFs face today

MRFs today are navigating multiple dynamics, including rising contamination from residents’ confusion on what materials are and aren’t recyclable, as well as volatile end markets and pricing resulting from global commodity trends and shifting demand.

Municipal customers pay the price for these challenges, since many municipal contracts incorporate processing fees that are designed to cover the costs of addressing these challenges and include a revenue share agreement that places most of the commodity risk on the community.

To improve the recycling system for all stakeholders across the value chain, we must begin with an increased focus on supporting MRFs.

The need for guidance

EPR laws for packaging and paper products (EPR for PPP) are now enacted in seven US states, with many other states already conducting needs assessments. EPR for PPP requires that producers (i.e. brands) that sell packaging and products take responsibility for recycling them at the end of their life.

That responsibility is sometimes operational, sometimes financial and often a combination of both. Some states require producers to cover the full cost of recycling programs, while others require partial producer funding.

EPR funds are expected to provide a significant boost to the US recycling system. Coupling this with guidance on operating standards and best practices for MRFs can drive increased material recovery and better system performance.

In states where MRF operating standards are established by EPR laws, the MRF Best Practices Guide can help these operators stay on top of regulatory requirements. In states without EPR, operators and their municipal customers can use the Guide to ensure that MRFs are operating at top form.

How best practices were developed

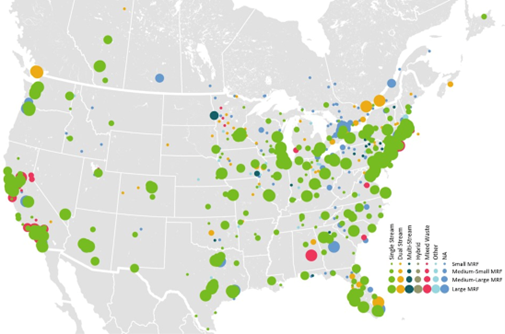

There are more than 350 MRFs in the US, varying substantially in size, sophistication, ownership and operating models. Most MRFs are privately owned and operated, while others are owned by, or operated in partnership with, public entities such as cities, counties or authorities. MRFs also vary in age and technology level.

The ability to upgrade or retrofit a facility to handle today’s material stream may be hampered by contractual structures that limit access to capital. Those that do upgrade may not fully consider the long-term maintenance, labor and operational requirements to keep the facilities running in top form.

To capture the operational realities of different MRFs, RRS identified and interviewed a range of MRF operators and equipment providers to collect input on key issues such as maintenance practices, operational procedures and staff management and leadership strategies. The learnings from those interviews informed best practices on:

1) Metrics and performance optimization, including key metrics to track (e.g. downtime, throughput) and their relation to MRF processing capabilities.

2) Equipment maintenance and spare parts management, including processes for tracking and management and the impact of implementation.

3) Facility management and staff organization, including approaches and tactics for employee retention, key roles and responsibilities of staff and meeting agendas.

4) Industry relations, including opportunities for increased consumer engagement, knowledge sharing among other MRFs and areas of support from equipment suppliers.

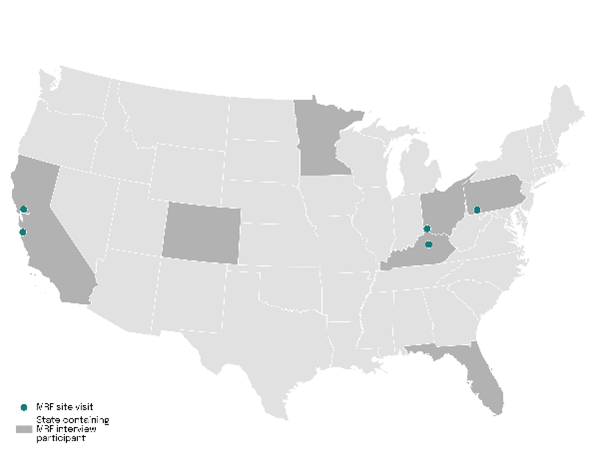

Once all key learnings were documented, the team visited five MRFs across the US to test best practices and ensure that the guide and its accompanying tools reflect operational realities on the ground. The visits focused on facilities managed by local governments or local or regional operators, based on the expectation that national or multinational recycling operators already have some documented best practices in place.

How best practices improve operations

While the MRFs visited all exhibited strong operations, the third-party assessment identified opportunities for improvement. The recommended improvements were often simple, but had not been previously recognized, since they were outside of a facility’s standard operating procedures. For example:

• Contracts: One MRF had strong operations and relationships with its customers, but lacked contractual measures to share the risk and cost of contamination with its municipal suppliers. The team identified the opportunity to incorporate provisions related to contamination, to help municipal customers understand the impact of improper recycling and justify investing in public education.

• Operations: One MRF was experiencing significant downtime related to loading materials in trailers for shipment to end markets. The team identified the opportunity to train staff to make shift changes more seamless and ensure efficient material movement.

• Equipment: Careful review of one MRF identified optical sorters that were not programmed to sort target material efficiently. The team identified the opportunity to dial in the sorters to improve recovery and reduce bale contamination and residue.

• Upgrade: One MRF had an outdated sorting system, lacking what is now considered standard sorting equipment (e.g. non-wrapping screens). The team created a pathway to modernize the facility through a retrofit. The facility recently completed an upgrade, supported by a loan from Closed Loop Capital Management and is now more efficiently sorting and preparing materials for sale, putting it on track to double its throughput.

These examples demonstrate the range of outcomes from applying best practices to different MRF operations. As EPR for PPP advances, and producers – organized through a producer responsibility organization (PRO) – are more directly engaged in recycling programs, the MRF Best Practices Guide offers a means to ensure consistent and strong MRF operations.

The guide, along with its accompanying implementation tools, helps ensure that all facilities, regardless of their ownership and operating structure, can work towards greater material recovery. Municipal customers can also rely on the Guide to improve the operations in the MRFs that handle their materials.

The guide can be used in the following ways:

• PROs or municipalities who contract with MRF operators can require that facilities use the guide and its tools to incorporate best practices and improve results.

• MRFs or local municipalities seeking to upgrade can look to the Guide for equipment best practices to determine investment priorities.

What’s next

The development of this guide is a major step toward documenting operational best practices for facilities that are at the heart of the US municipal recycling system. Its easy-to-use design and ready-made tools provide a clear path to improved efficiency and effectiveness at MRFs.

In addition to improving recycling outcomes, the tools also offer an opportunity for consistency in evaluating MRF operations, improving transparency and providing an opportunity for cross-training and information sharing.

As the MRF Best Practices Guide continues to be implemented across the country, the Closed Loop Center for the Circular Economy and American Beverage seek to document the impacts of these best practices, and share opportunities for improvement, advancing the foundation for a more circular economy in the US.