When Chad Hurley helped found YouTube in 2005, he likely had no idea the video-sharing website would later help his hometown tell the world about its new materials recovery facility.

When Chad Hurley helped found YouTube in 2005, he likely had no idea the video-sharing website would later help his hometown tell the world about its new materials recovery facility.

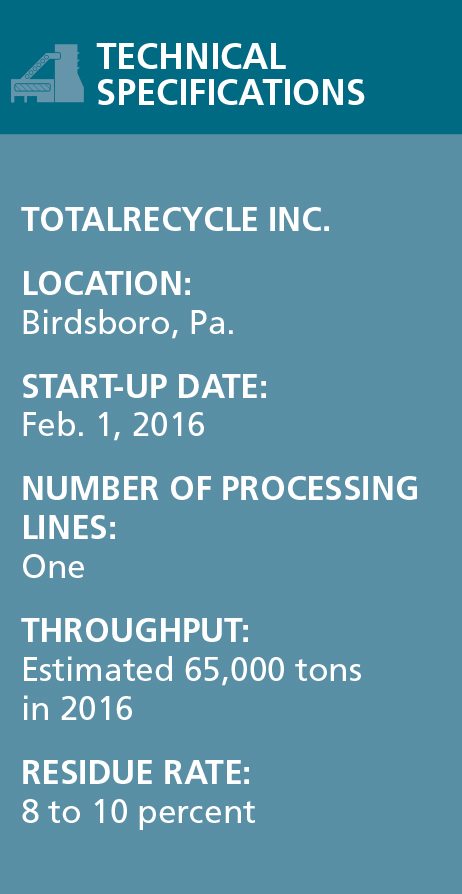

Birdsboro, Pa., where Hurley grew up, opened the TotalRecycle single-stream materials recovery facility (MRF) one year ago. A video from equipment company Van Dyk Recycling Solutions highlighting the facility and its technology has been watched about 2,600 times on YouTube.

The video is just part of the education and outreach efforts undertaken by J.P. Mascaro & Sons, the facility owner and operator. The MRF includes a 3,500-square-foot office with an on-site educational center.

“We strive to educate our society on the importance of recycling and feel that there is no better way to do this than to see the process firsthand,” said Joseph Paul (JP) Mascaro Sr., a third generation owner, plant manager and facility director. “Our educational studio allows the students and organizations who take a tour to recap their hard hat experience in an environment suited for learning.”

“We strive to educate our society on the importance of recycling and feel that there is no better way to do this than to see the process firsthand,” said Joseph Paul (JP) Mascaro Sr., a third generation owner, plant manager and facility director. “Our educational studio allows the students and organizations who take a tour to recap their hard hat experience in an environment suited for learning.”

The 75,000-square-foot MRF is engineered using stone block masonry instead of the typical aluminum siding. It sits on 14 acres near the Mascaro-owned Pioneer Crossing landfill and includes a public recycling drop-off building that accepts items not typically collected at the curb, including electronics, batteries and light bulbs.

The MRF is currently sorting 350 to 400 tons per day of fiber and containers. Residential material arrives in a single stream, although dual-stream material can be accepted as well. Commercial material arrives commingled and source separated, although contamination in the commercial mix is currently cited as the facility’s biggest challenge.

Van Dyk Recycling Solutions of Stamford, Conn. provided the sortation equipment for TotalRecycle. The company is the North American provider of Bollegraaf, Lubo and Tomra sorting equipment.

TotalRecycle’s single-stream line starts with a Bollegraaf drumfeeder, which ensures an even flow of material. After a pre-sort, material drops onto a Lubo triple deck OCC screen, which carries OCC across and drops smaller items onto a Lubo glass breaker screen. The screen removes glass and other two-inch-minus-sized material from the stream. Glass then goes to a Walair four-fraction glass cleanup system.

The rest of the stream heads to a manual pre-sort before it drops onto a Lubo anti-wrapping ONP screen, which is 12 feet wide and has 440 stars. Material then continues onto two additional screens with progressively smaller gaps to maximize fiber recovery.

Three-dimensional objects leaving the third screen are conveyed to a Tomra Autosort 4 optical sorter for final fiber removal. The sorter identifies both two-dimensional sheet paper and boxboard.

Remaining 3-D objects go to the container recovery line, made up of three additional Autosort 4 optical sorters targeting PET, HDPE and PP. A Bakker Inline Overbelt Magnet then removes ferrous metals before a Bakker eddy current separator removes aluminum.

The system is capped off by two balers – a Bollegraaf HBC-120S and a two-ram model from American Baler – capable of baling all commodities accepted at the facility.

The system is capped off by two balers – a Bollegraaf HBC-120S and a two-ram model from American Baler – capable of baling all commodities accepted at the facility.

TotalRecycle is the first single-stream facility for J.P. Mascaro & Sons, which serves eastern Pennsylvania and New Jersey. To see the video of the facility, visit vdrs.com/videos.

TotalRecycle Inc. employs 40 people on one shift Monday through Friday.

This article originally appeared in the February 2017 issue of Resource Recycling. Subscribe today for access to all print content.