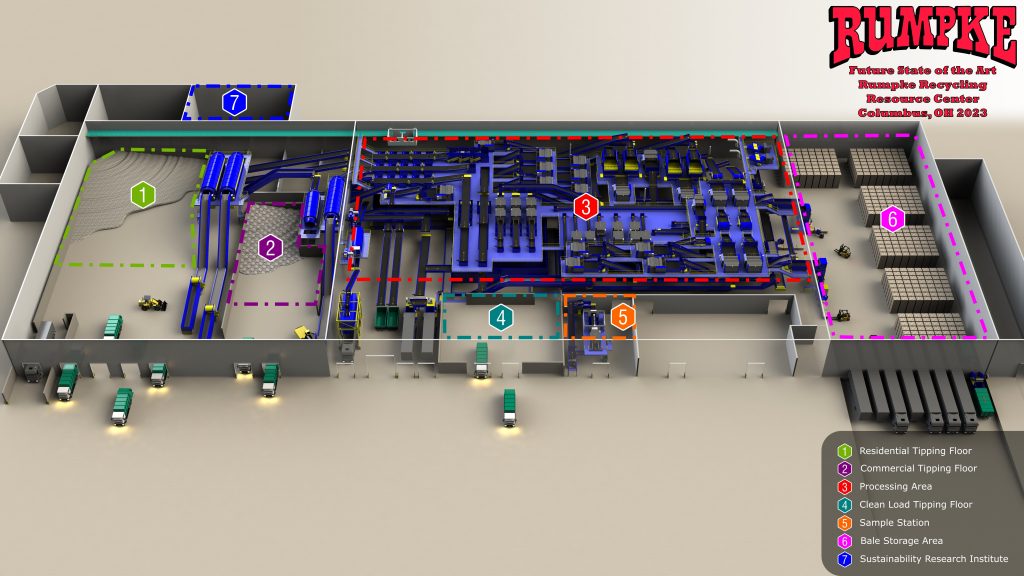

Set to open in 2024, Rumpke’s 200,000-square-foot MRF will be built on 25 acres the company purchased almost a decade ago. | Courtesy of Rumpke

Rumpke Waste and Recycling’s new $50 million materials recovery facility is designed to adapt, with plans for the Columbus, Ohio site putting a specific focus on PET.

“We’re not designing for two years from now, we’re not designing for three years from now, but for 20 years from now,” Jeffrey Snyder, Rumpke’s director of recycling, said in an interview with Plastics Recycling Update.

That includes changing how PET is baled, pre-sorting it by color for different end users.

The 200,000-square-foot facility will be built on 25 acres the company purchased almost a decade ago on Joyce Avenue with growth in mind. About a mile and a half away from a current Rumpke facility on Fifth Avenue, the Rumpke Recycling Resource Center will open in 2024, according to Snyder.

Snyder said the current facility is located downtown and not only houses a materials recovery facility (MRF) that processes 13,000 tons per month, but over 200 residential collection trucks, a transfer facility and the maintenance garage.

“If you come to our facility at 7 a.m., it’s organized chaos. With all trucks getting on the road, all the employees coming in, there’s just a lot going on,” Snyder said. “So what a great opportunity to be able to take advantage of what we did nine years ago and use the 25 acres on Joyce Avenue.”

The new facility will allow Rumpke to process 50 tons per hour instead of the current 30-45 tons, Snyder said. It will also allow the company to adapt more readily to the changing recycling stream and “start to recover more of the recyclables that we think we can do in the future.”

“Recycling is changing in a positive way to be able to accept more products,” Snyder said, pointing to PP, pizza boxes and other materials that years ago were not considered recyclable.

While the new MRF will let Rumpke expand what it can handle, Snyder said the company isn’t waiting around for construction to start. In January 2021, Rumpke started accepting plastic tubs, and this February also took on plastic, paper and aluminum cups.

The intent was always to include cups, but Snyder said Rumpke wanted to do a slow rollout.

Rumpke is also improving sorting technology at a MRF it owns in Cincinnati. A $1.6 million project in June to add three SamurAI robots from Machinex to the Cincinnati facility’s last-chance line, hitting on PP, helped the expansion of the accepted materials list. A $775,000 grant from The Recycling Partnership helped offset the cost, Snyder said. Since then, two more robots have been added to the Cincinnati facility.

Meanwhile, at the downtown Columbus facility, an optical sorter was reprogrammed to handle the tubs and now the cups. Rumpke hasn’t seen a huge change in the volume of material entering the MRFs with the additions, Snyder said.

Sorting PET by color

Rumpke is looking to go even “deeper into the stream” in the future. Snyder said plans include segregating PET by color prior to putting them in bales “to be able to provide the marketplace with a higher-value stream of recycling.”

“If you’re selling to a bottle manufacturer that’s making a PET bottle back into a PET bottle, they want the clear. If you’re selling to someone who is going to make the green translucent PET strapping, they want the green. So you start to think about as you go to end users, what are they really after and how can we design MRFs to provide more of what they’re after?” Snyder said. “That’s really the future of recycling.”

Once the MRF opens, the older facility on Fifth Avenue will close and the space will be used for more truck parking, Snyder said. The old equipment will be scrapped and recycled.

The key to all of the growth Rumpke wants to see is technology, Snyder said, and it’s already out there.

“We want to continue to be on that cutting edge. We want to be on the forefront and be the first to the table in the Midwest when it comes to recycling,” he said. “We feel we are the experts at it. We feel that we have the infrastructure to be able to handle all that. The future is having the technology to be able to do the things we need to do inside the MRFs.”

A version of this story appeared in Resource Recycling on March 1.

More stories about processors

- Major plastic initiative sets sights on system change

- California will fund mixed plastics facility, other projects

- E-plastics processor expands line of recycled board