This article originally appeared in the Winter 2019 issue of Plastics Recycling Update. Subscribe today for access to all print content.

China’s recent import policy changes have disrupted business-as-usual for the recycling industry.

Threatened by additional restrictions and tariffs, what is a state recycling program to do with a limited budget and no control over international policies?

The North Carolina Recycling Program is putting its modest funding to use to support the growth of local recycling markets. Through its annual grant program, North Carolina in 2018 encouraged private sector recyclers to respond to China’s import restrictions.

And the industry answered. Nearly a dozen companies are investing in projects to increase North Carolina’s capacity to process and consume materials, such as scrap plastics, that are no longer welcome in China’s ports. The result is a stronger local marketplace, creation of new jobs, and a statewide system of materials diversion that is less reliant on foreign buyers.

Past meets present

The North Carolina Recycling Program is housed in the North Carolina Department of Environmental Quality’s non-regulatory Division of Environmental Assistance and Customer Service (DEACS). This division provides no-cost technical, compliance, permit and financial assistance to businesses, government agencies and residents. Within DEACS, the Recycling Business Assistance Center (RBAC) supports North Carolina recycling businesses through funding opportunities and general assistance.

RBAC began issuing grants in 1990 through its Recycling Business Development Grant Program. Over the years, the grant program has steadily evolved into a major component of North Carolina’s recycling market development success. Each year, RBAC awards as much as $40,000 per company to North Carolina recycling businesses that are pursuing projects to expand their processing and manufacturing capacities.

North Carolina’s Recycling Business Development Grant Program provided a total of $60,000 this year to two ag plastic recycling companies to help them collect and process more nursery pots, mulch films and other items.

Between 2013 and 2017, RBAC awarded approximately $3.3 million to support 135 Recycling Business Development Grant projects. These projects catalyzed more than $27.9 million of private investment from the grantees, created 256 new jobs and increased processing capacity to recycle an additional 860,000 tons of material per year.

Following the implementation of China’s trade policy to ban imports of certain recycled materials, many communities and businesses are now seeking domestic markets for recycled materials that were previously exported. While the Southeast U.S. is faring better than other parts of the country, impacts are still being felt, with recyclers experiencing abundant supply and decreased market values.

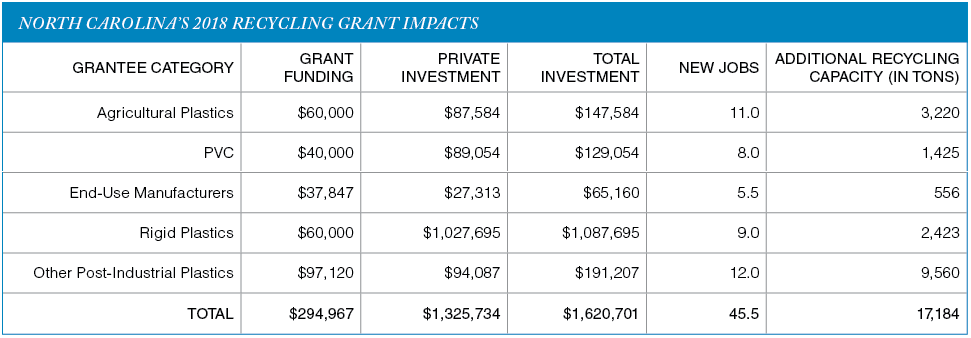

In 2018, RBAC directed $294,000 in grant funding to 11 businesses to increase the region’s capacity to recycle materials impacted by the new policies. Details on those grant projects are laid out below, illustrating how North Carolina stakeholders are addressing the Asian markets issue in tangible ways.

Helping to advance ag plastics

AEIPLUS and Verity Recycling are two companies in the Tarheel State that collect and recycle items like nursery pots, mulch films, irrigation tubing and other waste plastics generated by the agricultural industry.

RBAC awarded AEIPLUS a grant for $30,000 to help purchase machinery specifically designed to remove dirt, sand and other contaminants from mulch film and drip tape. The costly and time-consuming process of removing contaminants is an obstacle for many domestic recycling businesses that seek sustainable alternatives to landfilling this plastic waste. With the new machinery, AEIPLUS is able to quickly and efficiently remove contaminants from agricultural plastics, thereby increasing the marketability and profitability of recycling these materials.

Verity Recycling, meanwhile, received a $30,000 grant from RBAC to purchase a box truck to increase collection of plastic pots and film produced by small-scale nurseries. Previously, Verity had been unable to serve smaller nurseries that do not produce truckload quantities. With the new vehicle, Verity is able to efficiently collect plastic waste from multiple nurseries in one trip. This allows the company to expand its customer base and increase the volume of agricultural plastics recycled.

Possibilities in PVC

RBAC is also supporting the growth of domestic markets for hard-to-recycle plastics like polyvinyl chloride (PVC), which comes in a variety of rigid and flexible forms depending on what kinds of chemicals and additives were used in the manufacturing process. That fact makes it difficult for recyclers to determine a sample’s composition and how it should be recycled.

Commercial Plastics Recycling collects damaged PVC pipes from a number of different building and construction industries throughout North Carolina and surrounding states. It grinds the PVC into small flakes and sells them to piping manufacturers and other PVC end users.

In the past, the company only sourced materials from small-scale contracting and installation projects, but in 2018 RBAC awarded Commercial Plastics Recycling a $20,000 grant to help purchase an industrial grade pipe grinder. With the new equipment, the company can collect damaged PVC pipes from large-scale construction and demolition projects, increasing PVC recycling by more than 1,000 tons annually.

Another grantee, Brunson Recycling Corporation, recycles PVC and HDPE plastic film both in rollstock and loose film form from the medical manufacturing sector in North Carolina. RBAC awarded the company a $20,000 grant to help purchase an industrial-grade roll shear specifically designed for cutting large rollstock quantities of plastic. As a result, Brunson is able to process material more efficiently and increase quality control by identifying and removing contaminants. This purchase allows Brunson to process an additional 425 tons of hard-to-recycle medical plastic film each year and creates an opportunity for growth within the roll-cutting business.

Increased flexibility for rigid plastic firms

Many recyclers relied on China as a market for unprocessed rigid plastics. Following China’s ban on the import of all mixed plastics, there is an increased need for domestic sorting and processing of rigid plastics. RBAC awarded a total of $60,000 in grant funding to North Carolina recycling businesses that are increasing capacity to process these materials.

Envirovision Technologies, for instance, specializes in recycling large, bulky and dirty plastics that many other businesses either do not want or are unable to process. With a $40,000 grant from RBAC, Envirovision bought an industrial grade wash line that will enable it to capitalize on hard-to-recycle plastics, including intermediate bulk containers (IBCs), plastic drums and ethylene bales. With the new wash line, Envirovision is able to process and clean these plastics, resulting in an intermediate product that is more desirable for domestic markets and meets China’s new import standards.

Holmes Iron and Metal has a 60-year history recycling scrap metal. In 2012, the company began recycling rigid plastics, sourcing IBC totes and plastic barrels from manufacturing and packaging companies throughout North Carolina. Holmes shreds the plastics and sells it to other local businesses that further process the materials for manufacturing markets. With $20,000 in RBAC grant funding, Holmes plans to purchase a second shredder that will enable the company to perform more processing on-site and divert an additional 623 tons of plastic from landfills each year.

End-use encouragement

In 2018, RBAC also awarded nearly $38,000 to two businesses that manufacture new products with recycled content. By supporting North Carolina end users, RBAC is helping grow domestic demand for recycled materials, thereby reducing dependence on foreign buyers and protecting the industry from global market shifts.

Furniture maker HighCube recovers expanded polystyrene from a range of sources to make tables and other products.

Roll-Tech Molding Products specializes in using post-consumer and post-industrial waste materials to manufacture wheels, tires and bumpers, among other items. Roll-Tech received a $16,780 grant from RBAC to help purchase new injection molding and compression molding equipment. The machinery will enable the company to keep up with increased product demands and divert an additional 414 tons of scrap tires and 97 tons of plastic from landfills each year.

The other end user is HighCube, which collects expanded polystyrene (EPS) from local pharmaceutical, technology and distribution companies. HighCube shreds the EPS and uses the recycled material to manufacture eco-conscious furniture. RBAC awarded HighCube a grant for $21,066 to help purchase a new shredding machine. The equipment has enabled the company to collect more EPS from local businesses and divert a total of 45 tons of the hard-to-recycle material from landfills each year.

Other post-industrial recyclers

Following China’s adoption of stricter import standards, post-industrial recycling businesses with domestic markets or the capability to process plastics into flake or pellets have experienced an increased demand for their services. RBAC awarded three such businesses with a total of more than $57,000 to expand their recycling capacities.

Plastic Materials specializes in processing plastic films, foams, bubble wrap, rigids, and other rolled and baled forms. The company’s ability to process these hard-to-recycle materials has drawn interest from regional manufacturers that can no longer export their plastic waste to China. With $17,120 in grant funding from RBAC, Plastic Materials purchased two new forklifts to keep up with the increased volume of incoming shipments, allowing the company to boost diversion of plastic waste by 560 tons annually.

Meanwhile, Pelican Packaging Company has provided comprehensive plastic recycling to manufacturers for more than 20 years, steadily increasing its processing and production outputs. In 2017, the company reached its maximum processing capacity and needed to invest in new equipment to continue growing its customer base. With a $40,000 grant from RBAC, Pelican Packaging will purchase additional baling equipment to help the company process an additional 1,500 tons of plastic each year. With a higher capacity, the company can incorporate new waste streams from North Carolina into its business model, help clients divert additional plastic waste from landfills, and provide more raw materials to domestic plastic manufacturers.

Finally, Bromley Plastics Corporation has operated as a plastics recycler in North Carolina for more than 40 years. The company specializes in recycling plastics like polypropylene, polystyrene and nylon from post-industrial sources, including textile manufacturers and soda bottling companies. Bromley’s recycling process involves chopping and shredding materials for size reduction. The materials are then further processed and blended with additives to create plastic compounds that meet unique specifications of injection molding companies and other plastic manufacturers.

Using a $40,000 RBAC grant, Bromley purchased additional chopping/shredding equipment to increase its processing capacity. With the new equipment, Bromley anticipates recycling an additional 7,500 tons of plastic waste generated from regional manufacturing businesses.

Equipped to support ever-changing industry

While new policies in China and other import nations are causing short-term stress for the industry, the phenomenon also presents an opportunity for focused recycling-sector development in the United States. North Carolina is doing just that.

The state is home to more than 650 recycling businesses that employ almost 17,000 people locally. These companies depend on recyclables as raw materials in their processing and manufacturing operations. As the recycling industry adjusts to foreign import restrictions, North Carolina recyclers – and their counterparts in other areas of the U.S. – are facing rising processing costs, declining material values and the need to seek new markets.

With its long-standing commitment and almost 30-year history of recycling market development, North Carolina focused its 2018 business grants on projects that expand and develop in-state markets for materials affected by the foreign import ban. This private sector infrastructure growth results in higher value end products, stimulates local economic growth, spurs job creation, and helps to insulate both public programs and private businesses from global market changes.

As one of the few states offering this kind of funding and targeted support to develop private industry markets for recyclables, North Carolina is well-equipped to address the market challenges that arise in the ever-changing recycling industry. As shown in the chart above, RBAC grant projects will lead to an increased recycling capacity of more than 17,000 tons of material that will be sustained annually. This comes with an investment of $294,000 from the state that is matched with $1.3 million of private investment and creates more than 45 new full-time jobs in 2018 alone.

RBAC plans to build upon the success of the 2018 grant cycle by directing 2019 funding to stimulate even more statewide market development for materials impacted the foreign bans. The goal: resilient, effective, efficient statewide recycling systems that deliver economic and environmental benefits to North Carolinians.

Wendy Worley leads the recycling section within the Division of Environmental Assistance and Customer Service (DEACS) at the North Carolina Department of Environmental Quality. She can be contacted at [email protected]. Sandy Skolochenko serves as industrial development specialist and can be contacted at [email protected]. Timothy Shober served as a graduate student intern at DEACS and can be contacted at [email protected].