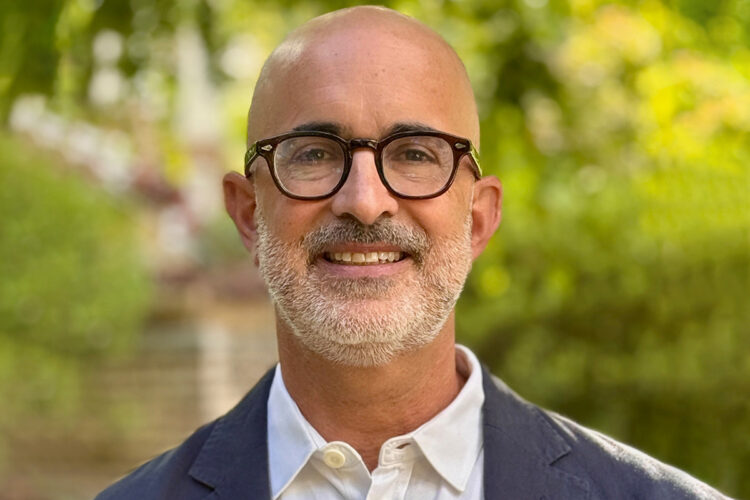

OnePlanet Solar Recycling, based in Jacksonville, Florida, has appointed Nathan Arbitman as its first chief commercial officer, as the company moves to scale solar panel recycling operations. The announcement follows OnePlanet’s $7 million seed round and plans for a $90 million industrial facility in Florida.

Arbitman said his remit centers on market development and customer growth across the solar value chain. “Fundamentally, my role is to help scale the technology and operation, but through an external focus,” he told E-Scrap News. “I’m laser focused on both growing the market for solar panel recycling and positioning our company as the leader in that space.”

The company is building out its River City project in Green Cove Springs, with commissioning targeted for 2027. “We are planning to start construction on the new facility next year and put it into operation in the first half of 2027,” Arbitman said. “We currently have the capability to process half a million panels per year. The new plant will be four to five times that capacity.” According to OnePlanet, the plant is designed to process more than 2 million modules annually by 2027, with expansion to 6 million by 2030.

In remarks made on the sidelines of the RE+ conference this week, Arbitman described the industry mood as realistic, but positive amid shifting incentives and demand. “There’s a kind of tempered optimism, where everybody here still knows that solar energy is the cheapest and fastest-to-deploy source of electricity in the world,” he said.

OnePlanet frames its expansion as a response to multiple demand drivers that are largely independent of policy swings, including repowering projects, weather damage and construction or shipping breakage. “All of those things are fully unaffected by the regulatory environment,” Arbitman said. “There’s lots of panels coming offline,” he added, citing retirements from installations that went into service 10 to 15 years ago.

In describing process consistency across generations of modules, Arbitman said the teardown steps are similar. “Whether a panel was manufactured 15 years ago or last week, each panel at the end of the day has an aluminum frame and a junction box that needs to be removed, glass that needs to be removed and recycled,” he said. “There are metals in there that can be reclaimed and put back into new value chains.” He added that OnePlanet has “designed a recycling technology that is especially made for the recovery of silicon, copper, aluminum, silver and plastic.”

Traceability and compliance are central to the pitch. OnePlanet provides legally binding Certificates of Recycling tied to service orders and maintains ISO 45001:2018, 14001:2015 and 9001:2015 certifications, while operating under federal rules such as RCRA and CERCLA.

Arbitman said customers increasingly expect documentation that follows assets from pickup through processing. “We should be able to provide a certificate of recycling along with a report to those customers that say, ‘this is what we received in and these are the materials that we were able to reclaim.’”

Arbitman most recently served as president and CEO of Endurans Solar, where he led an onshoring push, and previously held senior commercial roles at DuPont Photovoltaic Solutions and DSM Advanced Solar. OnePlanet CEO and co-founder André Pujadas said the hire aligns with the company’s next phase.

“Nathan’s deep understanding of the solar value chain, combined with his proven ability to scale clean technologies from pilot to commercial operations, makes him the ideal leader to establish OnePlanet as the solar industry’s go-to recycling solution,” Pujadas said in a press release. “His track record of building strategic partnerships and driving growth will be instrumental as we scale our operations toward our planned River City Project.”

Founded in 2023, OnePlanet says its goal is to keep millions of panels out of landfills while feeding recovered materials back into domestic manufacturing. The company’s River City project also received a $14.5 million Section 48C investment tax credit this spring in support of US advanced manufacturing.