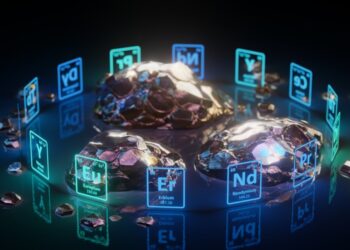

Domestic rare earth company MP Materials and major OEM Apple this week announced a collaboration in which Apple has committed to buy $500 million in magnets from MP. The project will involve the companies harvesting rare earth minerals from recycled electronics.

The agreement, announced July 15, involves a commitment from Apple to purchase rare earth magnets produced at an MP facility in Fort Worth, Texas. But most strikingly from an electronics recycling perspective, MP and Apple have agreed to collaborate on a rare earth recycling facility in Mountain Pass, California, where e-scrap magnets will be recovered.

“When complete, the new recycling facility in Mountain Pass, California will enable MP Materials to take in recycled rare earth feedstock — including material from used electronics and post-industrial scrap — and reprocess it for use in Apple products,” Apple wrote in a release.

Mountain Pass is also home to MP’s rare earth mine – the only such mine in the U.S. – where it extracts and refines rare earth elements.

The latest partnership with Apple comes after the companies have worked together for five years on technology that “enables recycled rare earth magnets to be processed into material that meets Apple’s exacting standards for performance and design. The companies will continue to innovate together to improve magnet production, as well as end-of-life recovery.”

The Apple agreement comes during a pivotal month for MP, which just last week announced it has formed a public-private partnership with the U.S. Department of Defense. That partnership, involving a “multibillion-dollar package of investments and long-term commitments” from the Defense department, will facilitate MP building another magnet manufacturing plant, bringing its total magnet production capacity to more than 11,000 short tons per year by 2028.

Amid global trade tensions that have affected the rare earth supply chain, the potential to recycle minerals from end-of-life electronics has drawn a renewed interest as one domestic supply line for the materials. Electronics recycling companies are experimenting with rare earth recovery in several ways, either through manually dismantling hard drives and separating the magnet for downstream processing, or even through recovering rare earths from a shredded e-scrap fraction.

Even before its MP investment, the Department of Defense has shown strong interest in rare earth recovery, which the agency views as part of a priority to expand support for domestic critical mineral production. Rare earths are used in a multitude of equipment that’s part of the country’s national defense system. To that end, early this year the department awarded funds to rare earth recycling company REEcycle, which disassembles hard drives from e-scrap facilities and data centers and harvests the magnets.