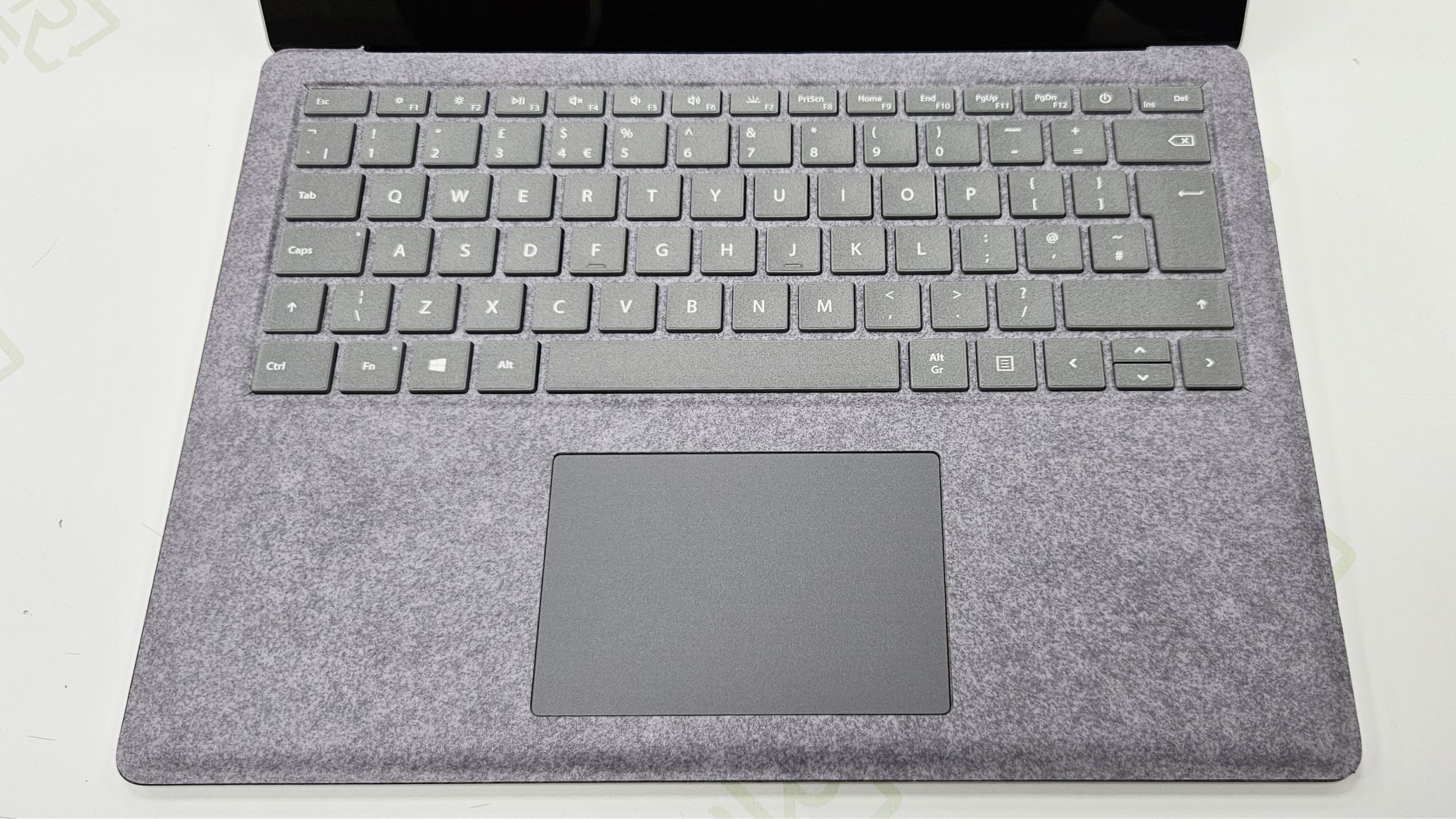

The Refurb Company provides a variety of stick-on products that can be applied during the refurbishment process to upgrade the cosmetics of a well-worn device. | Photo courtesy The Refurb Company

A company providing parts to refurbishers that increase used device value and marketability has opened a U.S. location in partnership with a domestic IT asset disposition firm, representing what company leaders say is a push to localize all aspects of the refurbishment process.

The Refurb Company USA started up this month, operating at the Farmingdale, New York, campus of ITAD firm IT Asset Management Group. The new operation is a collaboration between the ITAD company and U.K.-based The Refurb Company, which was founded in 2022 to provide repair and refurbishment products for ITAD and other repair businesses. Company leaders shared their goals for the project in an interview with E-Scrap News.

The Refurb Company’s products include stick-on keyboard keys made from plastic film, allowing refurbishers to create a clean keyboard appearance or even change the keyboard language, as well as phone and laptop skins made from plastic film that improve used device aesthetics and a line of “screen savers” that are pressed onto used device screens and improve their appearance and durability.

Before the partnership, those products were produced at The Refurb Company’s Poole, U.K., headquarters, and shipped to U.S. ITAD firms. But with the new collaboration, they’ll be produced in New York and be available for domestic sale across North America.

Leon Lindblad, founder of the U.K. firm and developer of the refurbishment products, said the idea behind providing in-country production is reflected in the company’s motto, “think global, refurbish local.”

“The philosophy is to produce locally for American refurbishers to be able to refurbish themselves,” rather than having to import the parts or export the devices for refurbishment elsewhere, he said.

Prior to founding The Refurb Company, Lindblad ran a refurbishment company called CFA Trading, which was acquired by a U.S. company in 2020. He developed some of the skin and sticky product technology while running the refurbishment operation, but honed it further with The Refurb Company.

“What we’ve developed over the last three years is a different world,” he said, noting the company is now providing device model-specific skins and color matching options.

Richy George, chief revenue officer for ITAMG, said his company began selling refurbished devices into e-commerce channels several years ago, seeing the opportunity for higher value recovery from direct-to-consumer sales. That meant paying more attention to the cosmetics of used devices, because used device marketplaces like Amazon or Back Market have stringent requirements for how used devices should look.

ITAMG experimented with painting devices, pivoted to using skins and eventually began using The Refurb Company’s products, which ITAMG chief operating officer Frank Milia said were “leaps and bounds ahead of any other product we’ve been able to find in the market.”

ITAMG leaders noted that using products like the screen savers can raise the value of the refurbished device significantly. For instance, Milia has seen the value of some assets triple, just from taking five minutes to apply a low-cost vinyl stick-on.

“Leon, over the last year or so, has created this product that you can apply on a Grade B screen, that can potentially convert it into a Grade A screen,” George added. From an ITAD perspective, it means potentially converting 10-20% of laptops that have Grade B screens into Grade A devices.

“The impact of that is huge,” George said.

Seeing the utility first-hand, ITAMG was interested in becoming a domestic supplier for other ITAD firms. Through the arrangement, The Refurb Company USA is now a separate entity that shares ownership with ITAMG and is a licensed producer of the U.K. company’s products.

“The company is loosely vertically integrated with our other refurbishing business, but it’s a standalone business to supply refurbishers across North America,” Milia said.

The domestic production allows the company to supply North American customers faster, and although the U.S. operation has been in development for over a year, it comes at a time of increasing tariffs, further disincentivizing global shipping.

Enabling ITAD firms to refurbish more products domestically rather than exporting those devices also provides a way to differentiate themselves in a crowded market, Milia said.