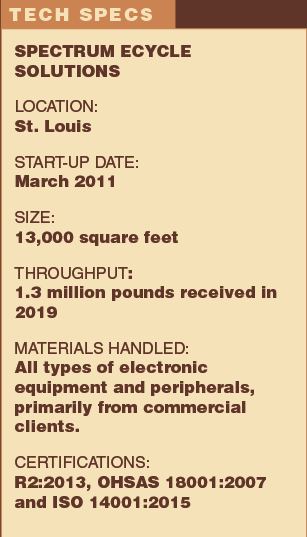

Spectrum Ecycle has 13 employees working out of a 13,000-square-foot facility in St. Louis.

With a drumbeat of mainstream media headlines emphasizing the importance of recycling electronics to recover valuable metals, consumers and businesses may question the need to pay fees to recycle their used devices.

Spectrum Ecycle Solutions tackles the issue head-on.

The St. Louis refurbishing and recycling company explains on its website that fees for some items are necessary to pay costs associated with ensuring data destruction, removing and properly disposing of hazardous materials, and maintaining voluntary certifications. The company also clearly explains that decreased quantities of valuable metals in devices challenge the economics of relying solely on commodity sales to support recycling.

“We love what we do and we’re happy to be part of the e-waste solution, that’s why we feel explaining why the process comes with costs that need to be offset may encourage you to recycle electronics and batteries more often,” according to the company.

Spectrum Ecycle has 13 employees working out of a 13,000-square-foot facility in St. Louis. The company primarily processes materials generated by local businesses, nonprofit groups and government agencies, although it does accept residential electronics from the St. Louis area, as well, said Dave Candelario, the company’s president.

Candelario said the company considers itself primarily a refurbisher. Last year, the company received about 1.3 million pounds of equipment; of that, Spectrum Ecycle was able to reuse about 30%. That reusable equipment generated about 80% of total company revenue.

When devices come in the door, staff members log the devices and evaluate them for reuse potential. Equipment deemed suitable for reuse moves through the refurbishing division, where it undergoes further evaluation, testing, repairs and listing for sale, either via wholesale or retail channels, Candelario said.

The company sells wholesale through a network of domestic wholesale buyers, and retail sales are primarily through Spectrum Ecycle’s eBay store. Resold devices are primarily IT equipment, but they also include medical/lab equipment, consumer electronics and collectible/vintage equipment, he said.

Equipment that isn’t reusable moves through the scrap processing division, where hazardous materials-containing components such as lamps and batteries are removed and devices are sorted by type. Removing the hazardous components allows the devices to safely enter downstream shredding and separation systems.

Equipment that isn’t reusable moves through the scrap processing division, where hazardous materials-containing components such as lamps and batteries are removed and devices are sorted by type. Removing the hazardous components allows the devices to safely enter downstream shredding and separation systems.

“Some demanufacturing is done manually at our facility, but most scrap devices and components are sent whole to downstream processors,” he said.

Candelario did note the company partially demanufactures devices with high-value components, such as telecom circuit boards, CPUs and reusable memory modules.

“We essentially base our level of demanufacturing on the scrap value of the internal components or if the devices contain valuable reusable components,” he said. “When scrap values were much higher five or so years ago, we were doing more demanufacturing.”

He emphasized that all data is destroyed, regardless of the value of the equipment. Spectrum Ecycle uses an Ameri-Shred model 150HD, which complies with NIST 800-88 for data destruction, to shred hard drives, DVD/CDs, VHS tapes, data tapes, floppy drives, audio tapes, and cell phones (if requested by clients).

Candelario, who worked for 25 years in corporate technology management before founding Spectrum Ecycle, said his company’s business model is rooted in its ability to adapt services to the unique requirements of clients while working within the rigorous framework of certification standards.

“We attract and retain a diverse set of clients with widely varying types of equipment. Our clients appreciate the ‘one-stop’ approach to our services,” he said. “We don’t restrict the types of equipment we process and we often customize our services to ensure our clients are compliant with their standards while also reducing their overall costs for equipment disposition.”

This article originally appeared in the Spring 2020 issue of E-Scrap News. Subscribe today for access to all print content.

Do you know of a processing company that should be featured in this column? Email [email protected]