Living Green handles a variety of devices, but mostly focuses on office IT assets.

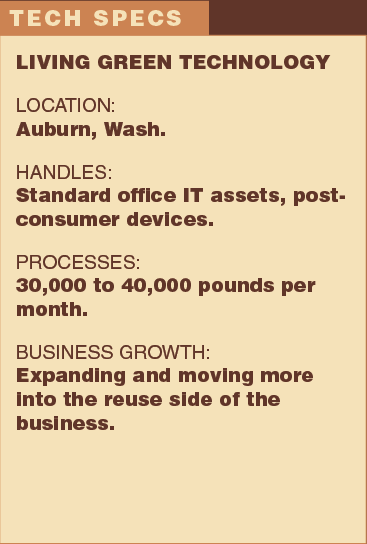

Over the course of three years, Seattle-area processor Living Green Technology has grown from a one-man show to a small business that’s well-positioned to serve the asset disposition needs of the Pacific Northwest’s tech sector.

Living Green handles a variety of devices, but mostly focuses on office IT assets, including computers, servers, monitors, networking equipment and voIP phones.

The company operates a 3,500-square-foot facility, located about 30 minutes south of Seattle in Auburn, Wash. Operating in a small space, Living Green doesn’t have its own shredder, so for devices that no longer have much reuse value, the company disassembles them by hand. Components are sent to downstream R2-certified recycling operations, such as Far West Metals in Oregon.

The company works in both the post-consumer and post-commercial electronics recovery sectors. On the commercial side, Living Green brings in used equipment from companies that are upgrading, moving, going out of business or in other situations that cause them to retire electronics.

The company determines whether a device will be recycled or reused based on a number of factors, particularly age. For instance, computers with Intel Core i3 and newer are being refurbished.

“The purest form of recycling is reuse, so anything we can put back into use, we want to put back into use,” explained Paul Weeks, business development and marketing specialist for Living Green.

Living Green processes between 30,000 and 40,000 pounds per month and is growing, Weeks said.

Living Green processes between 30,000 and 40,000 pounds per month and is growing, Weeks said.

Company owner Tyler Rivers started the business while working at a UPS Store in college. Rivers set up a drop-bin on the counter at work, collecting cell phones, iPods and other devices, repairing them and reselling them on eBay.

After initially repairing phones for some extra cash in college, Rivers began receiving calls about providing electronics recycling services for commercial clients. Rivers was renting a U-Haul and a storage unit and was performing ITAD services on his own.

Three years later, the company has six employees and hires contract workers as needed for bigger jobs. Weeks explained that the recycling operation is able to capitalize on the business boom in Seattle that is tied to the region’s growing tech footprint.

Living Green also looks for ways to get its name out into the community. It hosts public drop-off events and provides drop-off bins at businesses and community spaces, allowing residents to bring in post-consumer devices.

Although Weeks emphasized that both the drop-off collection side and the commercial asset recovery component of the business are important, he noted Living Green is delving deeper into asset recovery.

The company plans to expand further south into the Portland, Ore. market in the near future, either with a facility or by increasing its shipping activity between Seattle and Portland, which are located about 180 miles apart.

Right now, the company sends a truck to Portland from time to time to deliver e-scrap to its downstream processor, and also to collect devices through drop-off collection events.

Living Green has not yet sought certification but follows the R2 guidelines, Weeks explained.

This article originally appeared in the Winter 2019-2020 issue of E-Scrap News. Subscribe today for access to all print content.

Do you know of a processing company that should be featured in this column? Email [email protected]