This article originally appeared in the Summer 2019 issue of E-Scrap News. Subscribe today for access to all print content.

Savvy electronics recyclers, ITADs and computer refurbishers have long harvested device components as a way to maximize the value of their incoming streams.

Recovered parts can be used in a number of downstream markets. System rebuilders and refurbishers may use the parts in the manufacture of refurbished computers. Users may purchase components to upgrade existing systems and extend product life cycles.

Many components are easily interchangeable, and shrewd end users and equipment manufacturers leverage the cost, quality and availability of these items to meet their needs.

In short, parts harvesting can lead to reliable business opportunities. However, as the market and composition of electronic devices evolve, new strategies and techniques must be developed to make sure parts-focused processing remains efficient and profitable.

Evolution of the material stream

It’s been well-documented that the design of electronics has shifted, with lower precious-metal content and different constructions seen in seemingly every new line of devices.

The design shifts have also made parts reuse more complicated.

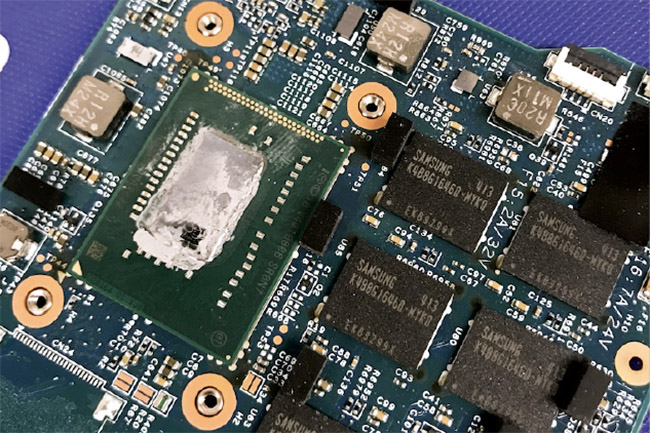

To achieve the lightness, thinness and durability expected by today’s consumers, items are often glued together, making disassembly and materials recovery much more difficult. Items such as memory, processors and persistent storage (hard drives), which once could be removed and upgraded by an educated user, are now soldered directly onto circuit boards, putting at-home upgrading out of the reach of all but the most sophisticated consumers.

Even if the consumer is willing to attempt to de-solder and re-solder these devices, there is significant risk that they may damage and render their device non-functional. This is due, in part, to placement of varying heat-sensitive components on the board.

In addition, many components, once easily removed, now require new capabilities to recover them for reuse. There is also significant risk of improperly performed processes damaging the recovered components, rendering them non-functional and worth nothing more than scrap value.

Those factors have all led to an environment in which expertise in device design and parts-harvesting techniques is more valuable than ever.

Know your numbers

Beyond CPUs, memory and hard drives, there are other opportunities to generate yield with parts. However, there is a very careful balancing act that must be applied. A smart operator will be guided by “tech cut lines” when deciding whether or not to harvest different components.

The tech cut line for a given stream defines which items are economically feasible to recover for reuse markets, compared with scrap valuations. Basically, the cut line is the point at which it makes sense to pursue a given part, taking into consideration testing, processing costs, costs of sales, packaging, freight, RMA management, and any other conceivable cost that could come into play when handling and selling the components.

The market of downstream buyers and expected recovery prices should be understood before pursuing any part. Other opportunities for value recovery are as diverse as the components found in the electronics stream themselves, and the quantity of goods being generated should be considered when trying to develop downstream component markets.

It’s important to remember the concept of “more is more.” That is to say, if you have one or two of a particular class of component, it can be very difficult to get a downstream buyer’s attention. However, if you have hundreds, or even thousands, of a particular type of item, the seller is in a much better position to drive strong value for the goods.

Selling isn’t always simple

When marketing your parts, there are several factors to keep in mind.

The quality and condition of your items must be accurately represented. Offering a warranty is a best practice, but it is important to understand how this will impact your bottom line in the event materials are returned. Terms must be clearly stated on invoices and when communicating to buyers to prevent any confusion after the deal is completed.

Also you and your buyer need to be on the same page about all of the factors of a transaction, before any product has shipped or money has changed hands.

Keep in mind that if an offer seems too good to be true, it probably is. In my experience, the deals that seem to have the most problems are those when we’re working with a new vendor. It’s tempting to try to squeeze out a few extra points of yield over an existing buyer. Of course, there are times when this can work out, but often, hiccups in the sale will arise. Extra sensitivity and attention to detail must be taken any time when working with a new partner.

Proper handling of material is another critical area. To maximize the value of components, parts should be properly handled from harvesting and through shipment to the buyer. Purpose-built containers – for example, RAM or CPU trays designed to hold the individual components – are well worth the added expense.

In particular, high-value components can have their worth seriously degraded by the presence of something as small as a single scratch. There are still markets for damaged or cosmetically imperfect items, but in general, improperly handling goods destroys value. Processes should be designed with maintaining the quality of cosmetics throughout.

CPU and RAM soldered onto a motherboard. Such moves by electronics manufacturers have made parts harvesting more challenging in recent years.

Put to the test

In order to ensure your harvest components have the market value you are expecting, an operator needs reliable processes of testing the items.

Some parts, like memory, have off-the-shelf solutions that can be purchased to assess the equipment, with a variety of tools available for different scales of processes.

Bench testers exist for lower-volume operations, and these require the individual plugging in of components for each part that is being tested. For operations handling a greater number of units, automated robotic handlers can help boost efficiency.

At the same time, some categories of components require recyclers or refurbishers to develop solutions themselves, due to OEM controls or the specialization required of the process. These scenarios require intimate knowledge of the component that is being tested, as well as an understanding of the downstream capabilities of your buyers. The goal is to match and meet your downstream quality requirements.

International intricacies

In addition to the complexity that can come with identifying, testing and inventorying parts, there are a number of global factors that have impacts on the business of parts resale.

Many countries have been increasing the scrutiny on the electronics scrap that crosses their borders – an example is Hong Kong’s Product Eco-Responsibility Ordinance.

Although the parts we refer to in this article are meant for reuse, and are not scrap, laws such as these create elevated burdens for recyclers and refurbishers in documenting their processes and packing their goods. The exporter must have systems of proving that items are bound for reuse markets, and are not end of life.

In addition, instability with the global norms of free trade have direct results on the market values of many components. Even if the trade of components does not have a direct tariff applied to it, tariffs have hurt the demand for the products manufactured by system rebuilders in some countries. That fact, coupled with a lack of confidence by rebuilders, has depressed the value of components in the secondary market.

Finally, weakening foreign currencies compared with the U.S. dollar means that the purchase of goods in dollars is more expensive for international buyers, which places downward pressure on pricing.

These factors have created headwinds for those trying to sell used electronic components.

Emerging opportunities

As the device stream evolves, the challenges and opportunities in components will continue to change over time.

Chip-on-board units, whether processors, memory, storage or embedded chips, will create new opportunities for savvy recyclers and refurbishers. Identifying these items in the material stream will require the training of employees so they know what to look for. A company’s traditional component buyers may not have the capabilities to service these new types of components.

At the same time, downstreams will need to adapt, and different processes are necessary compared with those that existed before.

What’s more, engineering and technical expertise required in harvesting embedded and soldered-on-board components is orders of magnitude more complex than previous iterations.

Nonetheless, businesses are stepping up to fill these gaps, and it will be exciting to see how these evolutions play out over the next several years.

Matthew Young is founder of Baltimore-based Electronics Value Recovery. He is the chairman of the Institute of Scrap Recycling Industry’s Functional Reuse Specifications Committee, defining industry-wide standards for the trade of reusable electronics. He can be contacted at [email protected].