Prices for PET, HDPE and PP bales saw significant drops again this month, with paper grades, plastic film and UBCs also marginally lower. Continue Reading

Continue Reading

Prices for PET, HDPE and PP bales saw significant drops again this month, with paper grades, plastic film and UBCs also marginally lower. Continue Reading

Continue Reading

A warm welcome back to “Women in Circularity,” where we shine a light on women moving us toward a circular economy. This month, I was pleased to connect with a regenerative system builder: Charlotte Boesch. Charlotte is a Senior Program Manager for the Billion Oyster Project, a nonprofit dedicated to restoring oyster reefs to New York Harbor through public private partnerships and education initiatives. Charlotte has over a decade of experience in stakeholder engagement and circular systems development. Continue Reading

A warm welcome back to “Women in Circularity,” where we shine a light on women moving us toward a circular economy. This month, I was pleased to connect with a regenerative system builder: Charlotte Boesch. Charlotte is a Senior Program Manager for the Billion Oyster Project, a nonprofit dedicated to restoring oyster reefs to New York Harbor through public private partnerships and education initiatives. Charlotte has over a decade of experience in stakeholder engagement and circular systems development. Continue Reading

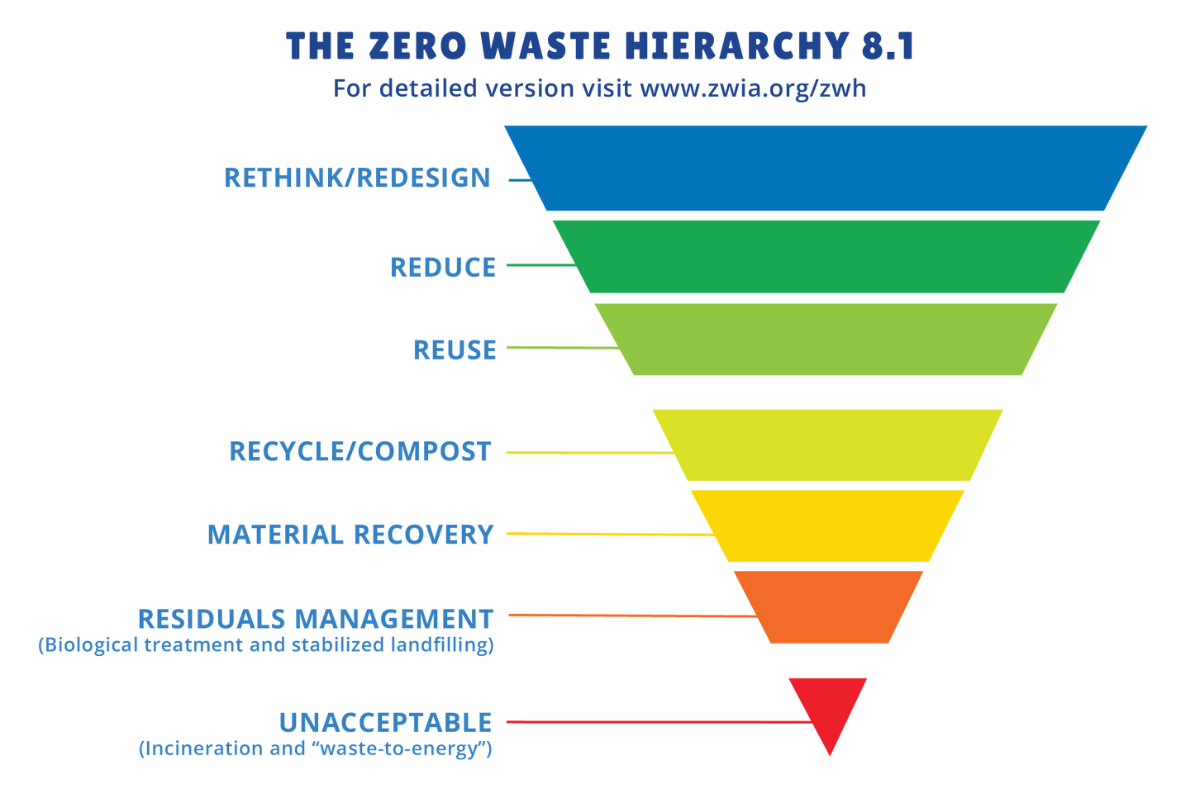

The Zero Waste Hierarchy was recently updated with refined definitions, a new guiding principle and more. | Photo courtesy Zero Waste International Alliance

Waste hierarchies have become essential tools for setting policy direction at every level of government. By clearly communicating which strategies are most environmentally and socially preferable, they help guide decisions on infrastructure investment, program design, and regulatory priorities. Continue Reading

AMP started out producing robotics but now supplies entire sorting facilities with advanced sorting equipment. | Photo courtesy AMP

Emerging extended producer responsibility programs for packaging are creating demand for more accurate data, higher diversion rates and a flexible infrastructure to handle changing material streams. An equipment supplier recently laid out how its artificial intelligence-equipped sorting systems can meet this need. Continue Reading

PET container prices fell 30% from June to July, part of an across-the-board price decline for curbside plastics bales. Fiber grades remained firm month over month. Continue Reading

PET container prices fell 30% from June to July, part of an across-the-board price decline for curbside plastics bales. Fiber grades remained firm month over month. Continue Reading

A warm welcome back to “Women in Circularity,” where we shine a light on women moving us toward a circular economy. This month, I was pleased to connect with a leader in community-based circular solutions: Teresa Bradley. Teresa is the CEO of Race to Zero Waste. Race to Zero Waste is a nonprofit dedicated to advancing zero waste principles and an equitable circular economy through education, action and advocacy to reduce single-use plastics and address the urgent challenges of our changing climate. Teresa has over 20 years of experience in zero waste operations and advocacy. Continue Reading

A warm welcome back to “Women in Circularity,” where we shine a light on women moving us toward a circular economy. This month, I was pleased to connect with a leader in community-based circular solutions: Teresa Bradley. Teresa is the CEO of Race to Zero Waste. Race to Zero Waste is a nonprofit dedicated to advancing zero waste principles and an equitable circular economy through education, action and advocacy to reduce single-use plastics and address the urgent challenges of our changing climate. Teresa has over 20 years of experience in zero waste operations and advocacy. Continue Reading

Recyclables saw an across-the-board price slump for June, with key fiber, plastic and metal grades notching slight or moderate decreases in value. Continue Reading

Recyclables saw an across-the-board price slump for June, with key fiber, plastic and metal grades notching slight or moderate decreases in value. Continue Reading

Sue Beets-Atkinson, global vice president of sustainability at SBM Management Services.

A warm welcome back to “Women in Circularity,” where we shine a light on women moving us toward a circular economy. This month, I was pleased to connect with a leader in zero waste facilities: Sue Beets-Atkinson. Sue is the global vice president of sustainability at SBM Management Services. SBM is a leading global services provider that helps corporations meet their operations-related sustainability goals. Sue has 32 years of experience in business waste minimization. Continue Reading

After a long runup, natural and colored HDPE grades saw sharp decreases in value once again in May, joined by drops in PET and PP prices. Mixed paper also declined slightly, while OCC remained steady.

WM, Republic and a city in Virginia announced upgrades and plans for new MRFs. | Ken Wolter/Shutterstock

The mayor of Portsmouth, Virginia, announced a new MRF with artificial intelligence-powered sorting. Meanwhile, Republic Services announced a new facility near St. Louis, Missouri, and WM completed improvements to an MRF in Colorado Springs, Colorado.