A significant retrofit at the GreenWaste materials recovery facility will feature heavy use of artificial intelligence sorting equipment and other technology.

A significant retrofit at the GreenWaste materials recovery facility will feature heavy use of artificial intelligence sorting equipment and other technology.

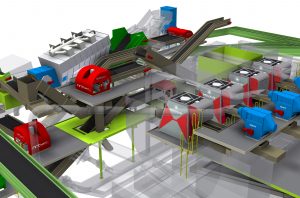

GreenWaste will install an assortment of new equipment from Bulk Handling Systems at its Santa Clara County facility, a mixed-waste processing plant that opened 10 years ago. The upgrade and expansion will double GreenWaste’s capacity from 40 to 80 tons per hour, according to a company release.

The new two-line system will include five BHS Max-AI Autonomous Quality Control robotic sortation units. Four of those units will work alongside three SpydIR optical sorters from NRT, to create what BHS describes as “a completely autonomous container line.”

The fifth Max unit includes dual robotic sorters and will be located at the end of the line as a final residue guard, aiming to recover plastics, metal and paper.

In a release, GreenWaste CEO Frank Weigel said the robotic sortation equipment will allow the company to accept more material while also boosting its diversion rate.

BHS is also supplying Tri-Disc screens to replace the existing trommel screen at GreenWaste, which the release described as antiquated. The new line further includes BHS bag breakers and polishing screens, Nihot single drum separators and a NRT FiberPure optical sorter that can sort out fiber and film.

GreenWaste, which was founded in 1991, collects and processes curbside recyclables, residential and commercial trash, organics and C&D debris. The company services San Jose and other communities in Santa Clara County, as well as Santa Cruz County.

More stories about MRFs

- AMP enters facility operations via RDS deal

- Recycling facility fires expected to reach new high

- Haulers feel effects of lower recycled commodity prices