alybaba/Shutterstock

This article appeared in the August 2024 issue of Resource Recycling. Subscribe today for access to all print content.

Editor’s note: This is the first of a two-part series exploring the concept of circularity. Part 2 is expected to be published in September’s issue.

Circularity has become the predominant but still vague goal for reducing packaging’s impact on the environment, without any direct conversation on what the word means or its limitations. The vagueness actually acts like a protective shield that prevents acknowledging the reality of material utilization and loss, including the unavoidable and overwhelming dependence on virgin feedstocks to make new packaging and its environmental implications. Let’s take a deeper look at circularity and related, overused metaphors in the recycling industry.

Our respective careers allowed us to gain a wide view of the recycling supply chain — the processes from material manufacturer to package manufacturer to brands and finally to retail channels; then to consuming and discarding containers by the public; to separating and prepping those materials at households for collection; then at MRFs and deposit centers for purification into raw materials; and finally to re-manufacturing into products or disposal at landfills. Material captured and cycled back in this process is a complicated journey rarely seen in its totality but is often idealized using the term circularity.

The targeted materials for residential commingled recycling have fundamentally changed with time. For the first time since modern, municipally-funded residential recycling programs began nearly 60 years ago, in a trend starting and accelerating in this century, more packaging than free fiber is now present in commingled materials. Newspapers, mail, printed and mixed writing papers have all declined to a minor fraction of the stream and are still receding from the dual impacts of computer and smartphone technologies. Some outcomes of this change were unexpected and expensive, and mostly borne by local taxpayers.

Until the last 15 or so years, MRFs were still being built around paper processing because that was the primary recycling output. Now they are going through massive re-tooling to capture more packaging and smaller-format materials. China’s market disruptions were caused in part because of an unacceptable amount of post-consumer packaging in bales, creating challenges for processing and price volatility. At the same time, paper packaging such as OCC, boxboard, fiberboard and paperboard became a universal addition to single stream for their value. Recently three-dimensional small- and medium-format fiber packaging, which is gaining prevalence in the stream, is demanding a processing response for proper capture. Sophisticated optical sorters and air-density separators, rather than the older and larger cascading screens, now focus on all sizes of paper packaging. In the current round of the estimated $2 billion to $3 billion in investments in new and retrofitted MRFs that started in the last three years, some facilities have eliminated paper screens altogether. This proves again that owning and operating MRFs is not for the faint of heart.

Similarly, plastic packaging proliferated in the marketplace due to its lower weight, high utility and usually lower cost. Though the pandemic temporarily slowed the amount of plastic in weight consumed by households, and despite some stiff regulations to reduce its use, plastic packaging is returning to pre-pandemic growth levels. The massive availability of cheap virgin petro-feedstocks certainly is an enabler of this process. In addition, this

increasing fraction of potentially recyclable material has become more customized in its various applications. And the fastest growing elements of this stream, film and flexible packaging, pose massive challenges to a recycling system that has not yet finished its last round of transformation. Will that force yet another mass transformation in MRF processing, and how will that be financed?

Plastics especially enjoy a flexibility (pun intended) that makes them more attractive than other more uniform and energy-trapping materials that are ideal for recycling and perhaps more naturally circular. The time from initial design of a new plastic package until it hits the retail environment can be as short as 16 weeks, as Polytainers reported earlier this year, for instance. Additionally, modern household plastic and multi-material packaging are made with an amazing array of increasing chemical, color and shape combinations, regularly achieving reductions in weight per unit. Today, each package’s physical characteristics are curated to provide the lowest cost, be attractive to buyers and provide specific functions, from food preservation to superior display capabilities in retail environments to ease of use.

The relationship between packages and consumers has continued to evolve as well. From a brand and packaging manufacturer point of view, it is easy to see the attractiveness of plastic packaging. Trending industry research has found techniques now common in modern package design that drive new purchases and repurchases at high levels. For instance, super lightweight packages, sometimes twice to three times the size of the delivered material, can extend the field of vision reception for better notice by passing eyes. In this and many other examples, packages catch the eye and present a retentive positive image. Consumer preferences to buy based on these types of packaging may hold sway, regardless of factors like brand loyalty or product satisfaction and overwhelming the rationality of caveat emptor. Packages have now become almost as important as the products they hold and are held up as part of the experience of buying goods or brand names. This increasingly important influence of home product package design has led to rapid shelf turnover and further customization as packages compete for demand.

These trends put more pressure on the entire material supply chain to respond, all the way to residential recycling programs and MRFs, who feel constant pressure to expand material acceptance, typically without any funding to facilitate acceptance or cover marginal costs for new packages. The most important implication is that packaging design innovates at a pace that outstrips the pace of recycling innovation and leaves little room or time to adequately explore trade-offs like package durability, such as for reuse, or like recyclability and yield — thus leaving open massive questions around how to get to circularity.

A brief history of circularity

The aspirations of circularity and the circular economy seem deployed in an uncountable number of published documents throughout most business ventures, often using complex language, ardent claims and untenable goals and focusing on recycled content and recycling levels. For simplicity, we use the terms circularity and circular economy interchangeably, noting the first is an encompassing principle and the second is an applied principle leading to a yet-to-be-realized economic system.

Circularity is metaphor for the endless cycling of the physical materials in packages after primary use with small to zero waste, by either reducing the need, reusing or recycling the material, or any combination, while conserving the most energy possible, with the fewest emissions, then bringing the material back to its cardinal intended use in packaging. Complete circularity is venerated as “closing the loop” — a closed system of material containment in a cycle.

The circular economy is a proposed economic system model, touted as regenerative and restorative and designed after stable natural systems, that uses circularity as its principle. The economic model provides wider umbrella strategies, inputs, outputs, feedback loops and methods to reduce, reuse and recycle materials endlessly to zero waste while conserving as much energy as possible. It’s meant to replace the still dominant and growing world linear take-make-waste model of extracting resources, producing virgin packages and disposing discarded package resources after use. It finally portends a perfect utility with the platonic justice of the multiple cycles used, each functioning as intended.

Circles, cycles and circularity have deep metaphorical attractions. Scholars have noted that cycles “are among the oldest ways of grasping human existence,” as a University of Cambridge Alumni Magazine article by Victoria James put it in 2022. To illustrate, in most major religions, the circle of life concept helps navigate emotional and perplexing processes in a closed cycle metaphor; human life and death are presented as part of a comforting cycle ending in either spiritual or physical rebirth, instead of the linear progression of birth to a physical death. For popular culture, a popular myth shared is that everything happens in cycles, which helps build hope or anxiety that the next point in time is predictably better or worse than the last. Sometimes a cycle concept is fully virtuous, where each point or condition along the circumference is a good result that gives rise to another that builds upon the first and so forth. Other times it is the opposite, or vicious.

These metaphorical cycles are what sociologists call umbrella concepts, used to enhance understanding of overarching concepts, feedback loops and actors relative to their impact on each other in a system over time. Psychologists have shown that this cycle thinking is valuable for assessing complex environmental, social, emotional and economic outcomes, and using them helps increase predictability when a predicate condition occurs. Cycles are useful in the sciences as well — for example, in the carbon cycle, the chemical process that was the gateway to higher life forms on Earth. In his classic “From Circular Economy to Circular Society,” M. Friant summarizes some of science’s most used cycle metaphors:

- Biogeochemical cycles of Earth.

- Ecosystem cycles.

- Resource cycles of materials and energy.

- Political cycles of power.

- Economic cycles of money and wealth.

- Knowledge cycles of technology, information, and education.

- Social cycles of care.

The concept of circularity for materials is a virtuous cycle. Like all beguiling metaphors, circularity can gloss over nuances and stark realities, including the powerful force of entropy, which is rampant in waste materials management, and external but ignored inputs (Is the carbon cycle possible without the sun?). In the world of materials, tools like life cycle assessments can help us pick apart nuances and apply analytics to the question, but they don’t change the overarching realities and their profound implications.

We could not leave this section without also addressing the word recycle, summarized by Merriam-Webster as to process materials or substances in order to regain material for human use. Unlike circularity, this definition conveys no inherent aspiration, and it does not promise endless cycling; rather, it is just the harvesting of some materials from waste to be used again. One can sense that inevitable material loss is just an accepted fact — we’ll grab what we can and plug it back into productive use. Luckily for us recyclers, though in circularity purgatory, recycling does provide a carbon-positive pathway away from current waste models.

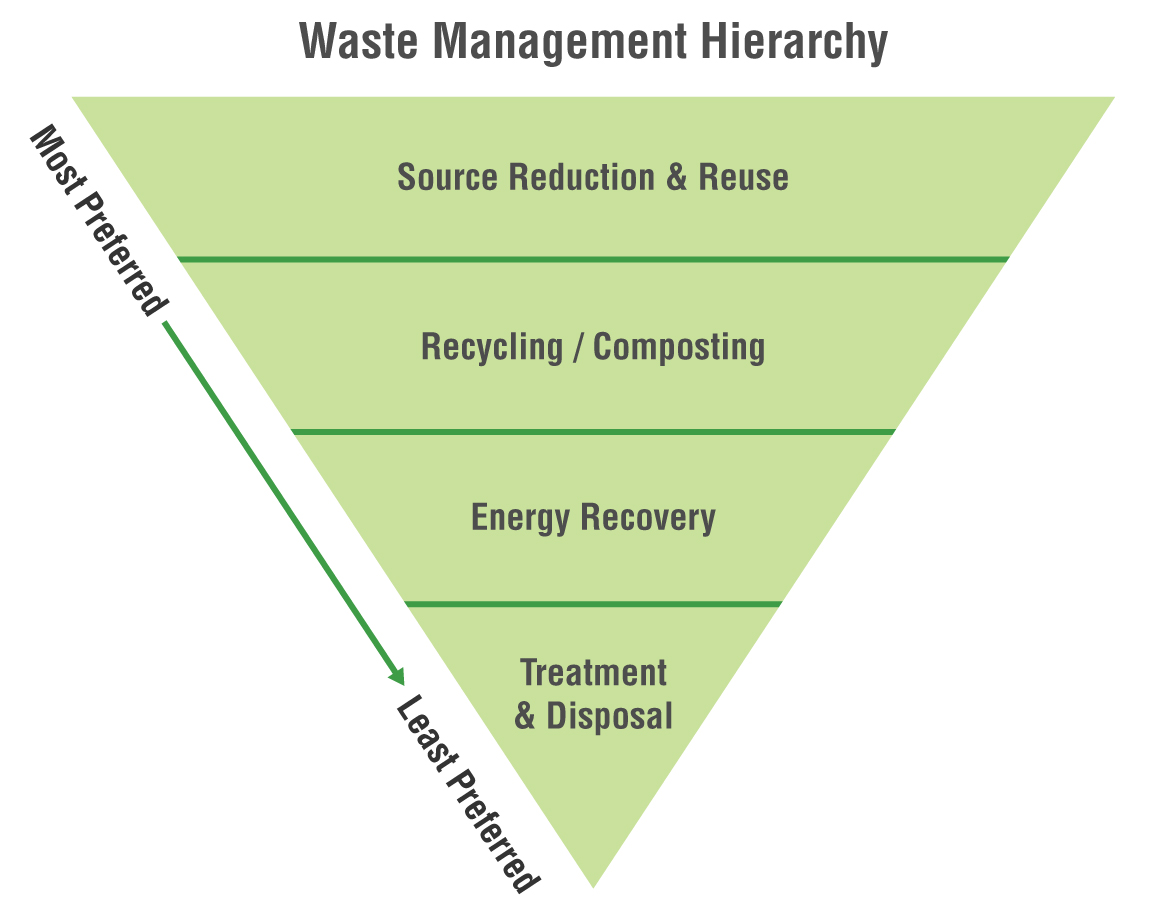

U.S. Environmental Protection Agency

From the waste hierarchy to circularity for packages

Last century, both the European Union and the U.S. EPA formalized policies around a waste hierarchy, the conceptual predecessor to circularity. This linear hierarchy aspired to minimize energy use and emissions, reduce landfilling and combustion and maximize resource conservation. This model has been productive, allowing waste planners to envision a world where the prioritization takes place and steadily moves materials waste management to preferred methods through policy, programs and investment. It has also been effective for communicating the most virtuous set of choices, and it allows a quick summary of current choices using the common strategies of modern waste management.

However, after over 35 years, the hierarchy has proved inadequate to move actors or address system complexities for inverting the triangle in the U.S. Its limited success, and perhaps its linearity, drove us to consider other conceptualizations and to try to accommodate a dynamic, expanding economy and the compelling urge for profitability and return on investment. The hierarchy in its simplest form seems to unquestionably accept unrestrained material extraction and consumption. The hierarchy then presents no answer to environmental crises in our aquatic and terrestrial systems, including the plastic waste crisis, atmospheric heating and its consequences, extreme losses in biodiversity, issues like PFAS and landfills as methane super-emitters.

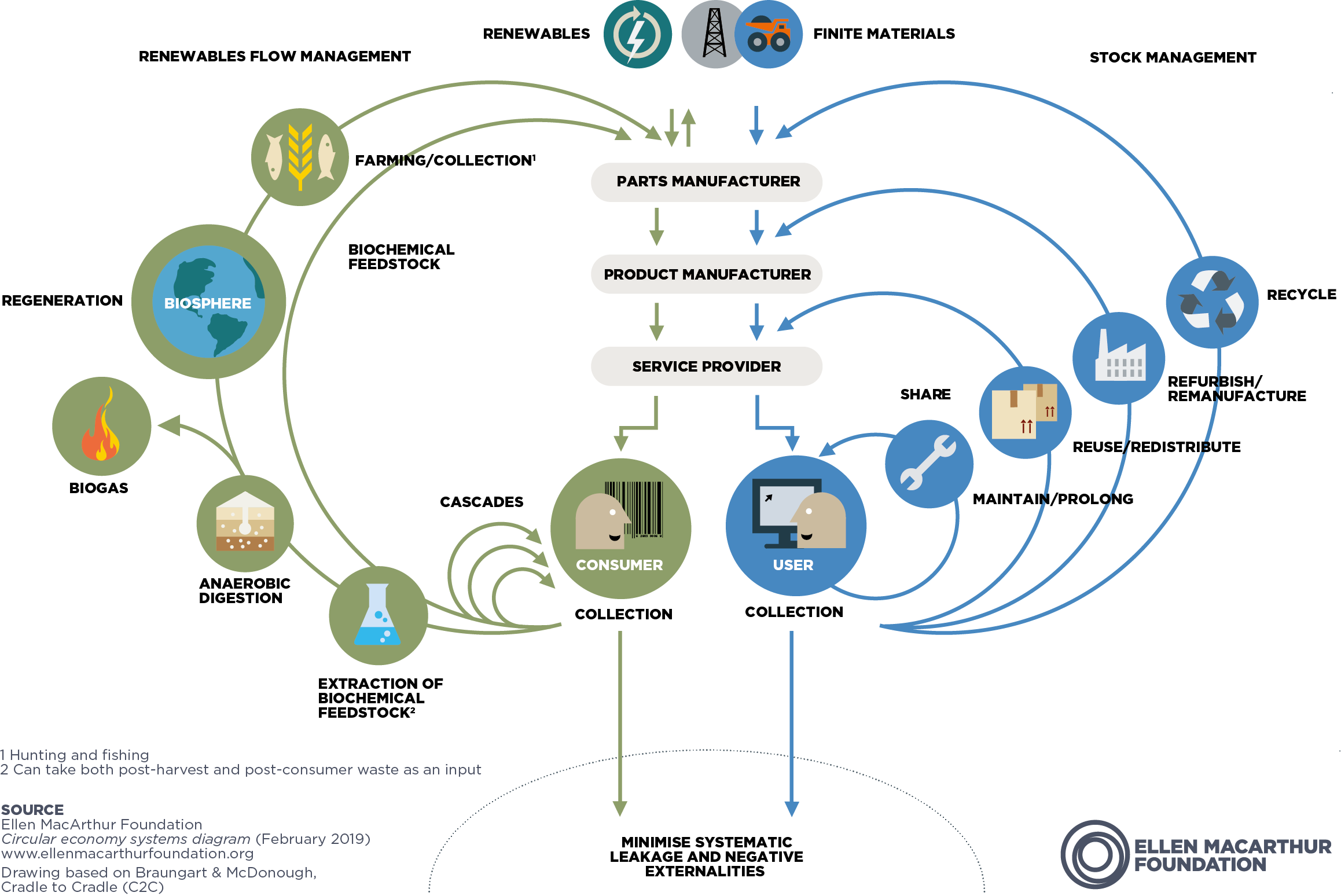

Inevitably, this led waste practitioners to search for a more inspirational model that almost by its very nature would mitigate the damage of material consumption — hence, circularity. Famous studies by Will McDonough in 2002 and McKinsey & Company for the Ellen MacArthur Foundation in 2013 were examples of the evolution of a new conceptual approach, introducing a paradigm for stakeholders along the entire value chain to consider. They argued compellingly that the cradle-to-grave model of human consumption is unsustainable. The linear take-make-waste system must give way to an alternative model where resource use is carefully designed, energy is conserved, and materials are endlessly cycled through an economy by reuse or recycling. McKinsey proposed a new economic model that mimics natural models of circularity, which is restorative and regenerative, rather than net-consumptive and hyper-productive. It is summarized neatly in the Palladian symmetry of the famous Butterfly Diagram. McKinsey and the foundation gave us the inspiring view that circularity would bring greater resiliency and security in an economy that will continue to grow because of the cycling of materials, much like natural forest grows and regenerates through natural cycles. It begs the question, though, whether economic expansion that humans value so much is possible under such a seemingly closed system.

Now, like the hierarchy, it’s time to question circularity before it becomes a hollow simplification that leads us to further inaction in the face of environmental crises. How exactly does this idealized view allow us to grapple with the physical nature of packaging and its rapid pace of innovation? How does it address, plan for and recognize the actual physical barriers for package capture from waste generation to MRF, loss in yield after capture from MRF to secondary processor to end market, and the inherent costs for providing enough of the stuff needed to fully cycle a package back to its original intended use?

Now, like the hierarchy, it’s time to question circularity before it becomes a hollow simplification that leads us to further inaction in the face of environmental crises. How exactly does this idealized view allow us to grapple with the physical nature of packaging and its rapid pace of innovation? How does it address, plan for and recognize the actual physical barriers for package capture from waste generation to MRF, loss in yield after capture from MRF to secondary processor to end market, and the inherent costs for providing enough of the stuff needed to fully cycle a package back to its original intended use?

In short, let’s really dig into packaging circularity’s limitations and the implications therein. Also, practical recycling might just be a long-term answer for some packages short of perfect circularity. Circularity promises big things, but to paraphrase Jimmy Buffet, God’s honest truth is it’s not that simple. If there are limits to packaging circularity, what are our options for addressing them? In Part 2, we will discuss how packaging is transformed in the recycling system, lay out some best practices to mitigate barriers and unstick recovery rates, and explore complementary strategies that could push beyond the boundaries of circularity. Circularity is a hopeful, essential and deeply inspiring concept. Let’s not make it a seat of self-congratulatory laurels to sit on while true growth in material recovery requires urgent action.

Michael Timpane has been a partner and vice president with RRS since 2015 and specializes in the recycling supply chain. He has worked for each of the largest post-consumer recycling companies in their time – Reynolds Aluminum, BFI, and WM – for over a decade each in his half-century career.

Scott Mouw is senior advisor for strategy and research with The Recycling Partnership. He comes from a background of public recycling, including directing the state of North Carolina’s recycling program.