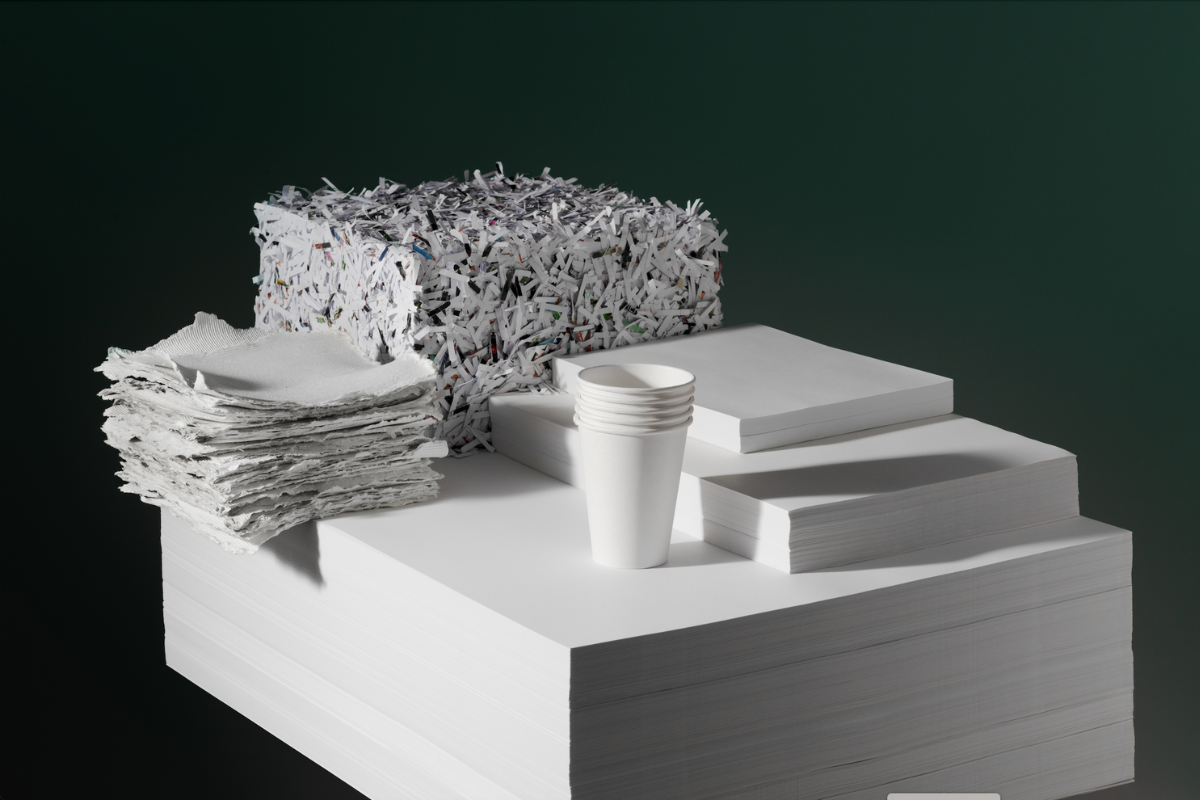

Three separate but connected companies – Sustana Fiber, Rolland Paper and Hanna Paper – rebranded as Sustana in mid-January. | Courtesy of Sustana

Sustana, a 100% recycled fiber mill operator and end user of recovered office paper and cartons, has consolidated its three business segments into the same entity. The move comes shortly after an acquisition that brought the Wisconsin-headquartered company into the fiber collection sector.

Previously three separate but connected companies, mill operator Sustana Fiber, paper manufacturer Rolland Paper and recovered fiber collector Hanna Paper are now different arms of one company: Sustana.

“We can pick it up, we can turn it into fiber, we make the paper and we can pick it up again,” said Renée Yardley, senior vice president of sales and marketing at Sustana, in an interview with Resource Recycling.

The rebranding, announced Jan. 16, is the latest in a series of moves toward vertical integration – a process influenced by the fiber market turmoil of the past few years.

Supply shift spurs acquisition

Sustana acquired Hanna Paper in August 2023, marking its first move into collecting fiber in-house. Previously, Sustana purchased all of its feedstock from brokers and other recovery operations. Hanna, which is now called Sustana Recovery, has eight locations in the U.S. and Canada. It collects 331,000 short tons of recovered fiber per year, primarily sorted office paper, including printer waste paper, the main grades Sustana uses.

“The acquisition there was for us to step back into the supply chain and make sure that our source of recovered paper for our two fiber mills was secure,” Yardley said.

Supply of Sustana’s main feedstock was upended in 2020 when the COVID-19 pandemic shuttered offices, schools and government buildings – all major generators of high-grade recycled office paper.

“All of a sudden, a lot of our sources of recovered fiber were gone,” Yardley said.

The company pivoted to take in alternative fiber streams, notably increasing its consumption of aseptic and gable-top cartons. Those remain a significant portion of Sustana’s feedstock today, Yardley said. But the disruption also spurred strategic planning around future fiber sourcing for the company’s two de-inked fiber mills, ultimately leading to the Hanna acquisition.

Yardley said Sustana is still buying fiber from other suppliers, but that acquiring the recovery operation “certainly secures a large portion of it.” The recovery division also collects fiber that Sustana does not use in-house and sells it on the market to other mills and end users, so it is a revenue generator as well.

Increasing recycled end product output

Sustana’s two 100% recycled fiber mills, located in De Pere, Wis. and Lévis, Quebec, process the recovered paper into about 255,000 short tons of recycled pulp per year. Some of that is fed to a paper facility previously known as Rolland Paper.

Located just outside of Montreal, Rolland (now renamed under the Sustana brand) produces 170,000 short tons of recycled paper products per year. It produces papers with 30% up to 100% post-consumer recovered fiber.

The company primarily produces uncoated freesheet, which covers a variety of office paper products, like copy and printing papers. Those are the same grades it collects for recycling.

Yardley said Sustana is “working on increasing the number of tons that we produce that are 100% recycled,” particularly because the more recycled content that’s included, the more Sustana can supply itself from its recycled fiber mills.

This story has been updated to note that Sustana primarily produces uncoated freesheet at its paper mills, rather than coated.