24K-Production/Shutterstock

This article appeared in the November 2024 issue of Resource Recycling. Subscribe today for access to all print content.

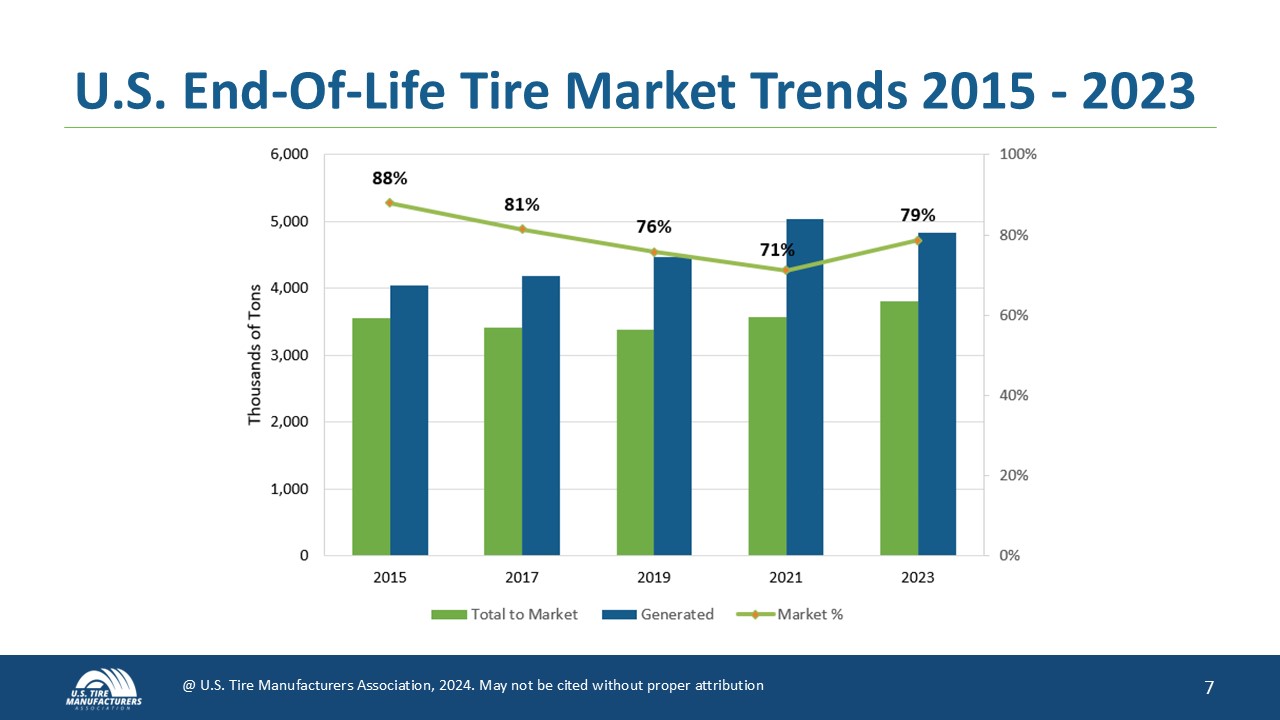

Tire recycling, by and large, means chopping up tires and doing one of two things with the pieces: using them as-is, such as in mulch or artificial turf pellets, or burning them for fuel. But these traditional markets haven’t been keeping pace with new tire generation, according to the latest data from the U.S. Tire Manufacturers Association, an industry advocacy group. And researchers, public officials and others across the country are working to push tire recycling in new directions, including into the same roads those tires once traveled.

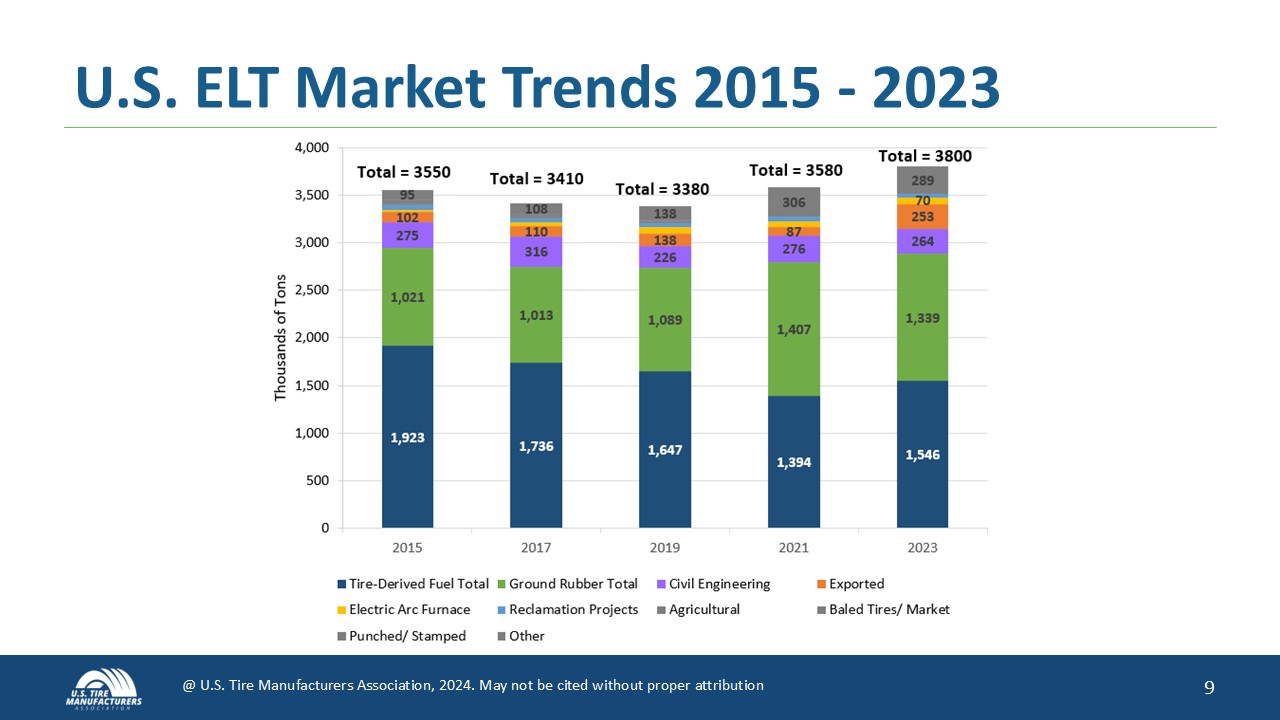

More than 3.8 million tons of used tires were processed into usable products in the U.S. in 2023, a 79% diversion rate, according to the association’s biennial End-of-Life Tire Management Report, the newest version of which was released in October. The figure was an uptick from 71% two years prior but was also the exception topping off a decade of decline from the peak of 96% in 2013, according to the association’s previous data.

John Sheerin, the organization’s senior director of end-of-life tire programs, said the bump was likely from temporary factors. The dip in miles driven at the height of the COVID-19 pandemic, for instance, meant a dip in used-up tires to manage, and higher natural gas prices resulting from Russia’s war on Ukraine made tire-derived fuel more appealing for furnaces, paper mills and similar facilities.

Barring these blips, U.S. tire consumption rises ever upward, Sheerin said, and the tide is against carbon-emitting fuels like TDF and the coal it often supplements. The problem requires development of end markets like rubber-modified asphalt, an association priority that has been gradually drawing more support at the state and federal level.

“We have a ways to go,” Sheerin said. Still, “a lot of things are going in the right direction, and there’s a lot of energy in the field right now.”

Street-level work

Street-level work

Used tires are of course a universal issue, often the biggest class of material collected by weight for the local programs that accept them. States from Alabama to California devote millions of dollars to grants and other programs for tire management, like the $2 million awarded by West Virginia to 22 businesses and local governments early this year. Connecticut in 2023 passed the country’s first statewide extended producer responsibility law for tires, which state officials expect to go into practice next year.

In Tennessee, state officials have taken deliberate steps to grow the used-tire supply chain, said Chris Pianta, an environmental program manager for the Department of Environment and Conservation’s Office of Sustainable Practices.

Since 2015, a small fee on new vehicles has gone into the Tire Environmental Act Program, which awards yearly grants for a mixture of private and public organizations. To build options and lower transportation costs, the first several years’ grants focused on increasing the number of local tire processors, Pianta said. The state has since gone from just one processor to half a dozen.

“I think we’re definitely in a better spot than we were nine years ago,” he said, noting that the grants over their history have contributed more than $10 million to 30-plus projects that diverted 7.6 million tires. “Hopefully we’re starting to make a dent.”

One such processor was Memphis Tire Recyclers, which started in late 2021 after its founders saw an opportunity in addressing hoarded and illegally dumped tires around the city, said Corteney Mack, its chief business officer and co-owner.

Memphis Tire received more than $460,000 from the state grant program in 2022 to buy equipment and facility upgrades, in some cases years earlier than the owners originally planned. The business now has three locations and customers buying all of the crumb rubber, tire-derived aggregate and tire-derived fuel it can make.

“It definitely helped take our business to new heights quicker than we anticipated,” Mack said.

Now Tennessee’s grant program has diversified into more, smaller recipients with projects that directly use scrap tire products, Pianta said. The bulk of this year’s $1.6 million in grants went to tire-rubber trails at state parks and other public areas, for example. Another $147,000 went to a Memphis nonprofit called the Binghampton Development Corporation to install bicycle lane barriers along 6 miles of city streets.

The BDC works to build job skills and work experience for communities in need, such as those with histories of substance abuse or with the criminal justice system, said Andy Kizzee, director of the BDC business hub. The organization has been around for two decades, but over just the past few years it has partnered with the city of Memphis, local professionals and others to recycle a variety of challenging materials. The push all began about three years ago with the confluence of two community problems.

“Memphis has the second-most pedestrian and bicycle deaths in the country, and we’ve got a huge illegal dumping problem,” Kizzee said. So a local urban planner, Laura Murray, partnered with a local industrial artist, Tad Pierson, and with the BDC to try to help both problems at once by converting dumped tires into barriers shaped like camelbacks, upright panels or three-leafed clovers. The barriers are bolted directly to the pavement and alert drivers if they start crossing the line.

Courtesy of Binghampton Development Corporation

Grants from the state tire program, the nonprofit People for Bikes and elsewhere funded a 1-mile pilot in 2022, and now the project is ready for another leap that’ll start in January, Kizzee said. And it will reach beyond dumped tires to make a bigger dent in the tire issue.

“We’ll be sourcing those from tire shops — small mom-and-pop tire shops that wouldn’t necessarily have a contract with a hauler or tire processor,” he said.

Into the asphalt recipe

Tennessee’s approach has also touched on a relatively small but growing trend toward rubber-modified asphalt, a type of pavement that incorporates finely ground tire rubber as an ingredient. The resulting mixture can extend road lifespans, reduce repair costs over time and bring other benefits, according to a state-of-knowledge report released in 2021 by the tire manufacturers association, the University of Missouri and The Ray, a nonprofit pushing for more sustainable transportation.

The technology has been the subject of testing in multiple states, including on several hundred miles of roads in Alabama, Georgia and Michigan. The University of Tennessee-Knoxville received a state grant of about $350,000 in 2023 for similar research.

A small sliver of old tires, about 3%, was used for asphalt applications in 2023, according to the manufacturers association report released in October. But the nation’s highways and roads represent a massive possible end market for the hundreds of millions of used tires generated every year, said Baoshan Huang, a professor in UTK’s Department of Civil and Environmental Engineering who’s overseeing the tire research project.

“The biggest potential application is to put it into asphalt pavement,” he said. “Our society, our community, does have a need to utilize this waste tire rubber, and also there are technologies that can use it more effectively.”

UTK is partnering with the state Department of Transportation to test the asphalt on sections of roads, developing mixtures and experimenting with such details as how much to de-vulcanize, or essentially cook, the rubber to get the best results.

It’s a common topic of research across the country, since every state sets its own pavement specifications and has its own climates and other concerns, said Sheerin with the manufacturers association.

“You can’t just throw some rubber in there and say it’s good,” he said. “They want to see work on the ground in their state that has lasted for some time.”

Sheerin reiterated the many potential benefits to rubber-modified asphalt, including its durability and its ability to be recycled multiple times as roads are resurfaced. The Tire Recycling Foundation, which works in concert with the association, received $3.8 million from the U.S. EPA in July as part of a round of grants supporting low-carbon manufacturing. The money is meant to help develop robust environmental product declarations that show environmental impacts across the life of a product, which could help spur more widespread adoption of the technology.

“At present it’s a relatively small market,” Sheerin said, “and it needs to grow substantially.”

Street-level work

Street-level work