This article appeared in the May 2023 issue of Resource Recycling. Subscribe today for access to all print content.

Following the passage of industry-supported recycling laws in California, Connecticut and Rhode Island, the mattress industry created the Mattress Recycling Council (MRC), a nonprofit organization designed to operate statewide mattress recycling programs.

Since 2015, these programs have recycled more than 12 million mattresses and diverted 450 million pounds of valuable commodities from landfills and incinerators. Today, MRC is a mature product stewardship program. Its focus has evolved to include supporting the mattress industry in sustainability initiatives, including the Sleep Products Sustainability Program, and initiating various research programs that prepare MRC for the future.

One such research endeavor is a life cycle analysis, conducted by an independent party, that recently found MRC’s California operations significantly reduce water consumption, energy consumption and greenhouse gas emissions. These environmental benefits reflect the savings achieved from recycled mattress materials displacing the raw materials and energy needed to manufacture new foam and steel springs.

Setting the stage

As part of a 2008 legislative mandate, California’s Department of Resources Recycling and Recovery (CalRecycle) contracted with UC Berkeley and UC Santa Barbara to study the full production and end-of-life management of carpets, carryout food clamshells, batteries and mattresses in terms of energy and greenhouse gas emissions. That study, conducted in 2012, concluded that significant energy and greenhouse gas reductions were possible if California encouraged mattress recycling.

California in the MRC era

MRC launched its California program on Dec. 30, 2015, and quickly grew its operations to allow for the capture and recycling of discarded mattresses from a variety of sources, including consumers, solid waste facilities and large-volume sources such as hotels and universities.

By 2020, MRC’s California program was a mature and highly functional recycling system with quality data being collected from all aspects of the value chain. Conducting a life cycle analysis of a post-consumer collection program was unusual, but it was also a logical project for MRC to undertake to measure the baseline environmental footprint of its program.

In that same year, MRC commissioned the aforementioned life cycle analysis to study, quantify and evaluate the environmental impacts and benefits of each component of its California program. The results of the study document the environmental benefits MRC provides and will guide the trajectory of our research projects and operational focus to achieve other goals.

The analysis

After a competitive review process, MRC selected Scope 3 Consulting from Santa Barbara, Calif. to conduct the life cycle analysis, based on their work with other consumer products and the involvement of one of Scope 3’s principals, Brandon Kuczenski, in the state’s 2012 baseline mattress study. This was a complicated multi-year project that MRC hoped would provide valuable information for stakeholders and the mattress industry.

The scope of the study included all environmental impacts and benefits associated with each component of the program, which include:

Collection: MRC aggregates discarded mattresses through a variety of collection channels, including collection events, drop-off at public collection sites and direct pick-up from large-volume sources such as hotels and universities. The starting point for the study began at the point of collection for each of these possible channels.

Transportation: The study quantified the environmental impacts of transporting over 15,000 loads of mattresses throughout California by measuring the distance of every haul from each collection point to one of nine recycling/deconstruction facilities. Most of these transporters used diesel fleets to move common 53-foot trailers.

Recycling: In 2021, MRC’s contracted recycling facilities dismantled 1.6 million mattresses and box springs. The study measured the environmental impacts of each operation’s use of labor, equipment, energy, water and supplies to quantify the environmental impacts of the deconstruction process.

End markets: By weight, 76% of the mattresses and box springs received by MRC’s recycling facilities were reused or recycled into new products or, in the case of box springs, wood that can be burned as biomass fuel. The primary materials extracted from discarded mattresses are steel and foam. The recovery and recycling of those two components drives most of the environmental benefit for the program by displacing the production of virgin foam and steel products. Non-recyclable materials constituted 23%, by weight, of the mattresses and box springs processed. The study quantified the environmental impacts of disposal alternatives, including landfilling, incineration, pyrolysis and gasification.

Scope 3’s process required a deep dive into a variety of environmental indicators, including greenhouse gasses, energy demand, water use, particulate matter and smog emissions from each part of MRC’s program to quantify these environmental impacts. For more details on the study’s methods and findings, read the full report at www.mattressrecyclingcouncil.org/lca-report.

The findings

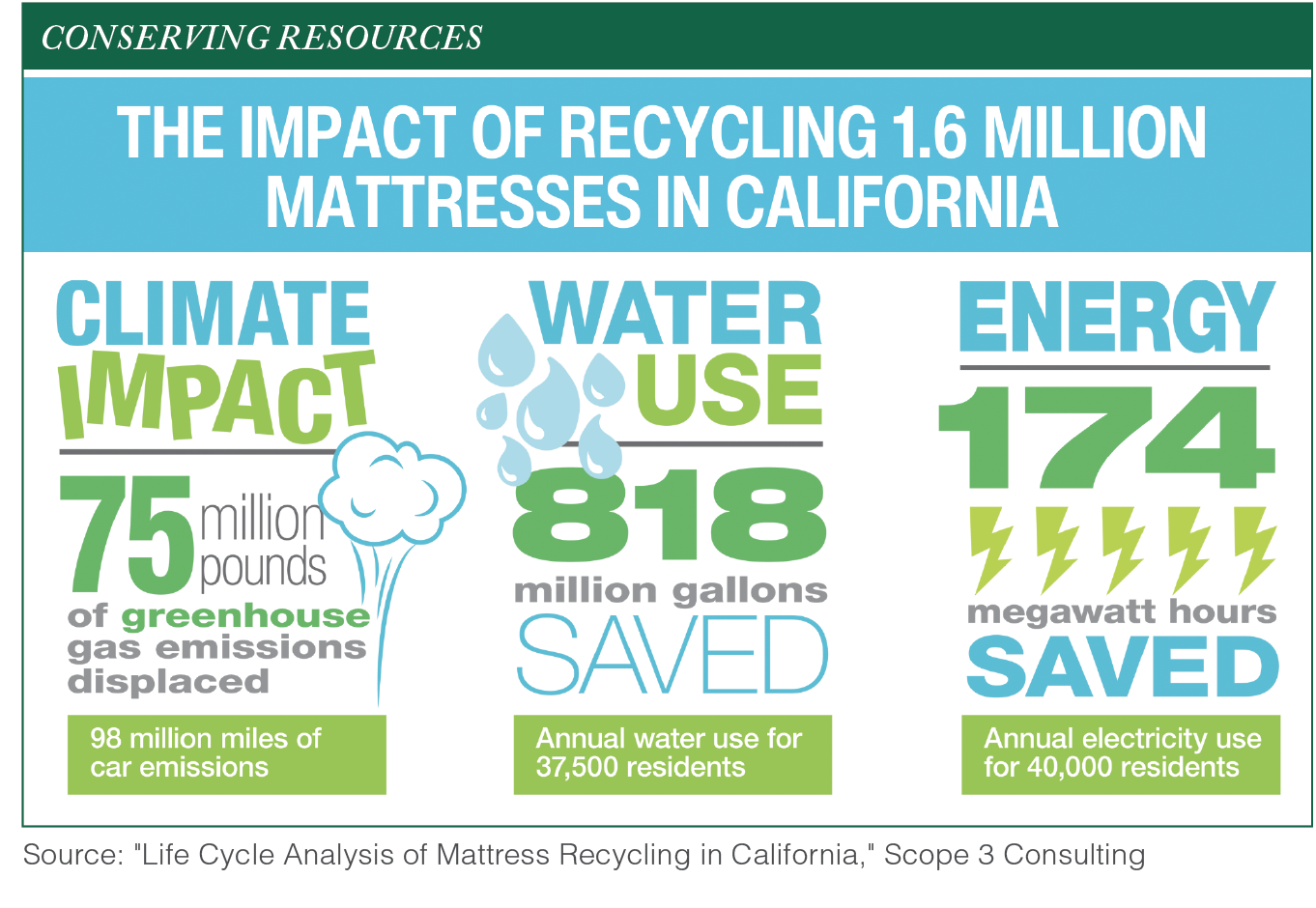

The study found that recycling 1.6 million mattresses per year generated the following environmental benefits:

- 75 million fewer pounds of greenhouse gasses emitted, equivalent to the emission savings from driving a gas-fueled vehicle nearly 100 million fewer miles.

- 818 million gallons of water saved, equivalent to the annual consumption by a city of 37,500 residents in one year.

- 174,000 kilowatt hours of power saved, equivalent to the amount of power a city of 40,000 residents would use in one year.

Stated differently, the materials reclaimed from every mattress recycled save 500 gallons of water, enough energy to power the average household for three days, and reduce greenhouse gas emissions by the equivalent of driving 60 fewer miles.

Turning research into action

MRC did not wait for the study’s results to start making changes. Knowing that transportation would be a significant contributor to its greenhouse gas emissions, MRC has begun actively managing its transportation network to reduce hauls and miles driven, thereby reducing associated carbon emissions.

Likewise, MRC can further displace carbon emissions and other environmental impacts by increasing the recycling of mattress components that are otherwise landfilled.

This study documented that mattress recycling provides an impressive number of benefits across a broad spectrum of environmental indicators. For MRC, the assessment will help guide investment and research decisions, inform policy discussions and allow the organization to evaluate its programs with an eye on its environmental footprint.

Mike O’Donnell is MRC’s chief operating officer, with oversight of all aspects of the program, including the research team. He has over 30 years of experience managing solid and hazardous waste collection programs for public and private entities, including product stewardship programs for mattresses, paint and mercury-containing lamps. He can be reached at [email protected].

This article appeared in the May 2023 issue of Resource Recycling. Subscribe today for access to all print content.