This article originally appeared in the August 2019 issue of Resource Recycling. Subscribe today for access to all print content.

Since 2012, the state of Oregon has steadily expanded the conversation about the impacts of materials to include the whole life cycle. This means that impact assessment starts with resource extraction and includes manufacturing, distributing, usage and managing discards. Oregon’s 2050 vision for sustainable materials management places solid waste and recovery activities in this larger life cycle context in order to pursue higher-order goals of conserving resources and reducing pollution.

The need to better serve broader environmental and social goals, such as achieving a stable climate, led the Oregon Department of Environmental Quality (DEQ) to recently commission research that opens a new question in the evolving discourse about packaging: Do bio-based, compostable, recycled-content and recyclable materials consistently result in lower impacts to the environment when impacts are measured across the full life cycle of those materials?

This article lays out how we sought an answer to that question and what the findings entail.

Attributes versus impacts

Many individuals, institutional purchasers and policymakers wish to lower the environmental impacts associated with their choices. In addition, many of those impacts – for example, greenhouse gas emissions, resource depletion and the emissions of toxic chemicals – can be estimated quantitatively using a life cycle assessment (LCA). An LCA does not address all impacts (such as impacts from marine debris), and the results can be context-dependent.

Many individuals, institutional purchasers and policymakers wish to lower the environmental impacts associated with their choices. In addition, many of those impacts – for example, greenhouse gas emissions, resource depletion and the emissions of toxic chemicals – can be estimated quantitatively using a life cycle assessment (LCA). An LCA does not address all impacts (such as impacts from marine debris), and the results can be context-dependent.

Because of the inherent complexity of the LCA approach, most people instead use descriptive attributes such as “recyclable” as a shorthand way to communicate environmental “goodness.” It is widely believed that attributes such as recyclable indicate that a material is inherently better for the environment. But is this a valid assumption?

Working with Franklin Associates, an LCA consultant, DEQ conducted a meta-analysis of existing literature. The process drew upon existing LCA studies, rather than commissioning original analyses. This allowed the researchers to understand the overall trends based on a large body of published research. Franklin Associates reviewed existing LCA studies from across the globe that were published between 2000 and 2017.

The scope of the study encompassed two groups of materials (packaging and foodservice ware) and four attributes (recycled content, recyclable, bio-based and compostable). This article covers only recycled-content and recyclable attributes for packaging. Reports on all four attributes are available at tinyurl.com/DEQresearch.

Because LCA studies can rely on different accounting frameworks and background data, only “paired comparisons” within the same study were used. For example, a container with recycled content could be compared against another with no or lower recycled content, but the containers would also need to serve the same function and be modeled for impacts using the same accounting framework and data sources.

Results from such a paired comparison for any one type of impact (such as ecotoxicity potential) counted as one “comparison.” The available research produced several thousand of these examples.

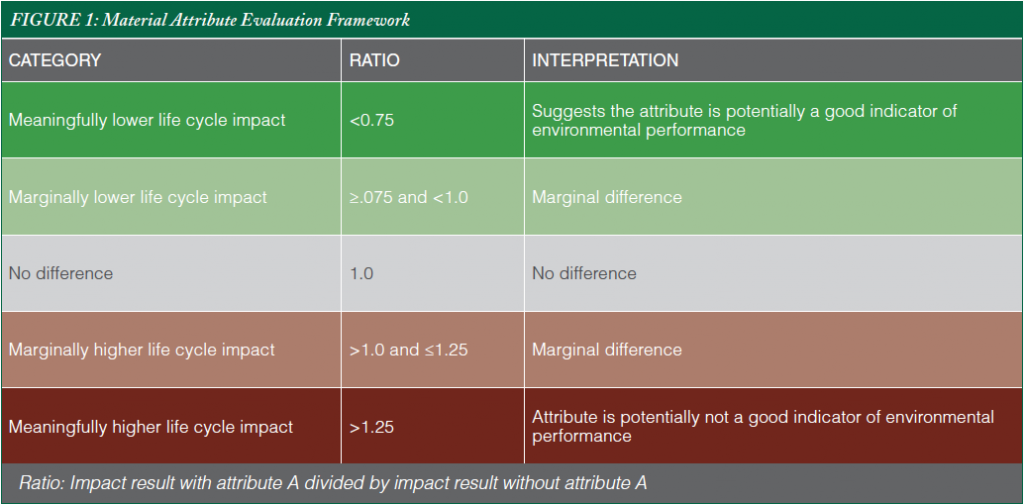

To aid in visualization of results, an algorithm was created to categorize findings. This system involved the calculation of a simple ratio. For each paired comparison, the ratio is the impact category result for the package with the attribute of interest, divided by the same impact category result for a functionally equivalent package without or with less of the same attribute.

Ratios less than 1.0 suggest that the attribute points in the direction of environmental preference (fewer toxics, less energy use and so on). Meanwhile, ratios greater than 1.0 show a higher impact. Given uncertainty in many LCA studies, we also drew a distinction between “meaningful” and “marginal” differences. The conclusions and recommendations of this study are based on the “meaningful” differences.

The categorization system is shown below in Figure 1.

Results for recycled content (same materials)

Recycled content is material that has previously been used, is recovered after usage, and is then utilized again to make new products.

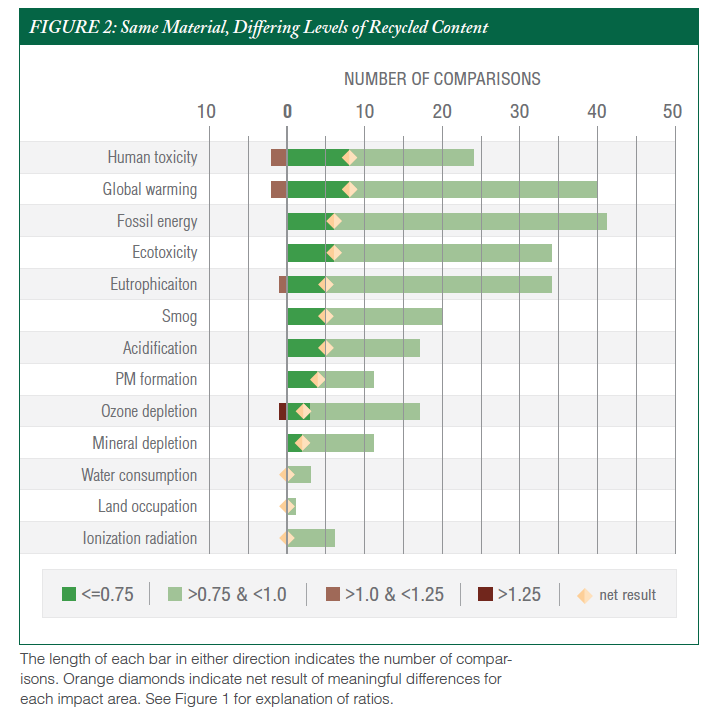

Figure 2 below contains the results of comparisons for packages made of the same materials, but with varying degrees of recycled content. An example of this would be comparing impacts of a 30% recycled content PET bottle with impacts of a virgin PET bottle. In this case, the research is investigating different products using the same material and serving the same function, but with different levels of recycled content.

The length of each of the bars in Figure 2 indicates the number of comparisons found in the literature. Green shows that the attribute is associated in the literature with lower impacts (good); red shows the opposite (bad). The orange diamonds indicate the net result of meaningful differences for each impact area – the further the diamond is to the right of zero, the more the literature suggests lower net environmental impact; the further to the left, the more the literature suggests higher net impact.

Figure 2 shows that when we increase the recycled content of a material, we almost always improve its environmental profile. This finding demonstrates that recycling can be part of a strategy to reduce environmental impacts. (In this case, “recycling” refers not to collection and processing, but rather the use of previously used materials by industry. Of course, the benefits of recycling also depend on proper infrastructure for material collection and processing.)

Results for recycled content (different materials)

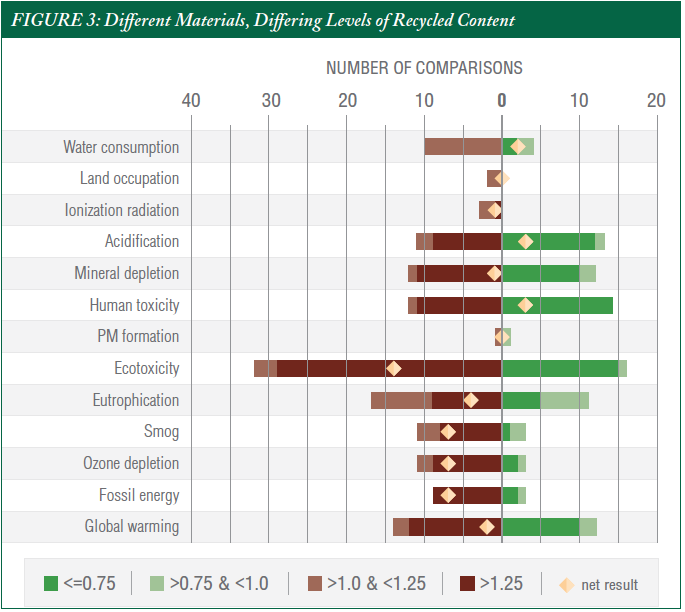

Figure 3 shows the results of comparisons for packaging made of different materials – a package with recycled content compared with a functionally equivalent package with less or no recycled content made from different materials.

An example of this is juice delivered in a glass bottle with recycled content and the same juice delivered in a plastic bottle without recycled content. Figure 3 only includes results from life cycle assessments that provide full credit for using the recycled material in order to show the best case scenario for the recycled content attribute

The results suggest a mixed pattern – making decisions solely on the presence of recycled content does not consistently point to lower-impact solutions when different materials are available that serve the same function.

In other words, if the material to be used is known, increasing the recycled content reduces environmental impacts across most impact categories (as shown in Figure 2). But when multiple materials can serve the same function, recycled content alone is an unreliable indicator of reduced environmental impacts.

This is because materials are inherently different in terms of their production and have very different environmental profiles before consumer use. The impacts of acquiring and transforming the feedstock as well as manufacturing are significant contributors to impacts. These impacts are reduced to an extent by using recycled materials, but the offset credit (for example, energy savings) does not always equate to lower environmental impacts overall when compared with different materials.

Results for recyclable packaging

Recyclable packages are those that have reasonable potential to be transformed into feedstock for use in the manufacture of a new product. “Recyclable” is not the same as “recycling” but rather is an attribute of design and purchasing that describes the potential of something to be recycled.

The DEQ-Franklin study did not evaluate recycling as a supply-side strategy (comparing managing discards via recycling versus disposal) because it is well established that proper recycling at the community scale is a beneficial activity to both society and industry.

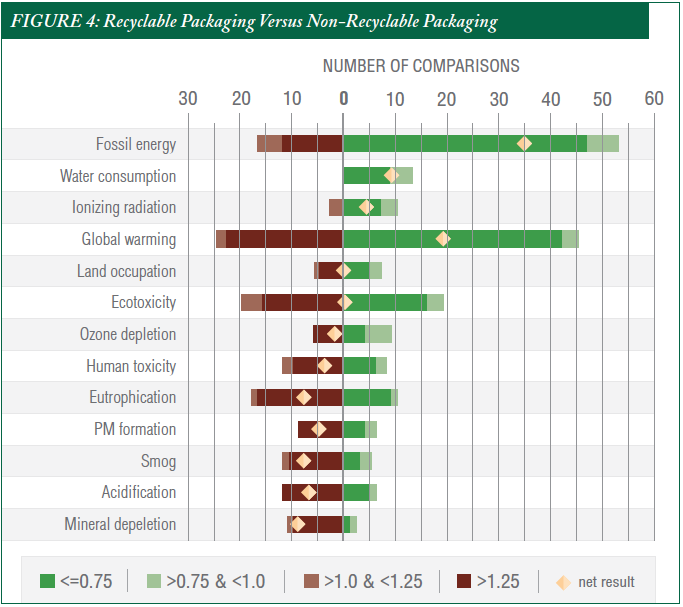

The question asked by the research team was: How well does the recyclability of a package predict reduced environmental impacts? Figure 4 below shows the results of comparisons of recyclable packaging with different packaging that is either not recyclable or is recycled at a lower rate.

Here again, the results are mixed. Solely using recyclability as the basis of a design or purchasing choice does not guarantee a reduction of environmental impacts. For example, delivering coffee beans in a steel container that is fully recyclable in local programs across the country has higher impacts than delivering the same product in a non-recyclable flexible laminated bag (more on this example below).

Future recycling versus current recycling?

One limitation of the DEQ-Franklin approach is that it relies on studies that typically used recycling rates current at the time the original studies were published. But future recycling rates could be higher. Does that make a difference?

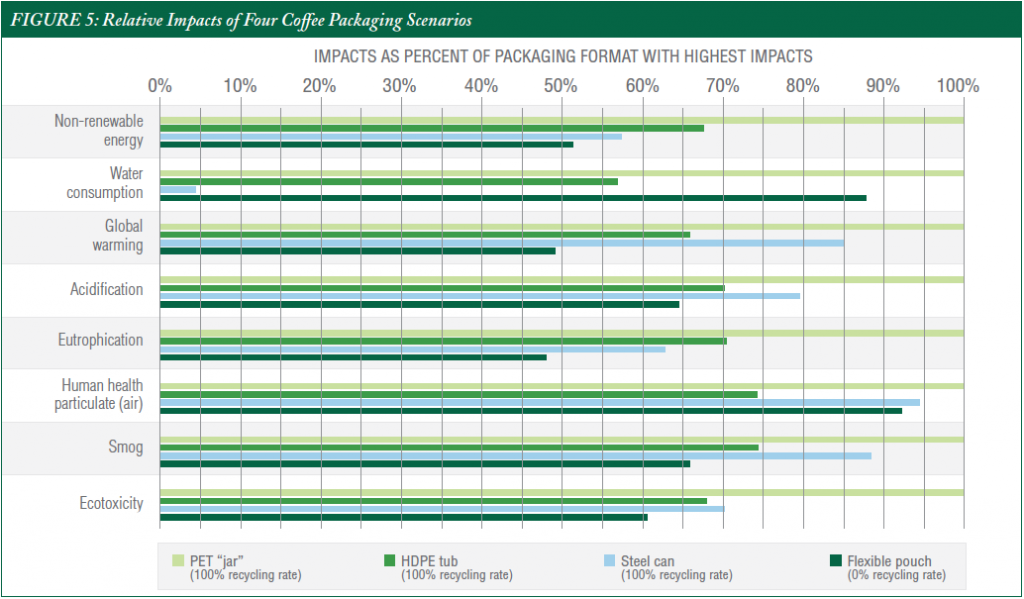

To assess that dynamic, DEQ conducted original modeling of life cycle impacts for four commonly used packaging formats for coffee: a steel can, HDPE tub, PET “jar” and flexible bag. The first three containers are currently accepted in many curbside programs and in theory could be recovered at high rates. The flexible pouch is not currently recycled.

DEQ modeled impacts for a future in which 100 percent of the recyclable containers are recycled. To further bias the results in favor of recyclable packaging, we also assumed that all lids, closures and labels would be recycled at 100%, that all recycled materials displace virgin feedstock at a ratio of one-to-one, and that achieving “total recycling” can be done with no higher pollution or per-unit inputs (fuel, for example) than what is attributable to recycling today.

In contrast, we assumed no future improvements or impact reductions for the non-recyclable flexible pouch. We did assume that non-recyclable materials are properly landfilled or incinerated. This represents a close approximation of U.S. conditions, but it is not representative of conditions in all other countries.

Results are shown in Figure 5 below. Even under the most optimistic (and arguably unrealistic) recycling assumptions for rigid containers, the non-recyclable flexible pouch results in the lowest impacts for six of the eight impact categories considered, including global warming.

A few factors lead to the results in Figure 5. First, the ratio of packaging to product was the key contributor leading to differences in the overall environmental impact of each scenario. The PET option had the lowest product-to-packaging ratio (3.8 to 1) of any of the packages analyzed. Conversely, the plastic pouch ratio was 20.0 to 1. This means that to deliver the same amount of coffee, the PET jar requires five times as much material as the plastic pouch.

Some secondary factors influencing the results are the inherent differences in production and recycling of the specific packaging materials – for example, the rate of material losses during the recycling process.

Sustainability and circularity

As momentum grows for increasingly ambitious “zero waste” and “circular economy” commitments, this research provides three important reminders.

First, municipal solid waste is only one small part of the life cycle of materials. In the pursuit of higher-order goals, such as reducing pollution and minimizing overall resource use, end-of-life treatments such as recycling done well are beneficial, but by themselves are insufficient.

Second, making decisions that optimize the end of life of engineered materials without considering impacts across the full life cycle can lead to unintended and potentially negative environmental outcomes. Simply requiring materials to be recyclable (and recycling them) does not guarantee that such materials will result in the lowest overall impacts to the environment. Similarly, not all recyclable materials are the same – some have lower life cycle impacts while others have higher impacts. Concepts such as the circular economy can be interpreted very broadly, but narrow interpretations that focus only on landfill diversion and material looping can result in trade-offs.

Finally, “circular looping” is not a guarantee of sustainability. While recycling and composting may reduce the environmental impacts of materials, the net impacts may still exceed science-based limits for sustainable withdrawals of resources and emissions of pollutants. The literature reviewed in this study showed that when evaluated using the quantitative approach of LCA, recyclable and recycled materials can be better than alternatives, but they can also be worse. Simply requesting these attributes is not the same as assessing environmental impacts.

To achieve higher-order goals of environmental protection, packaging options need to be evaluated for impacts across their full life cycle. This will allow designers, buyers and policymakers to better select options that truly reduce environmental impacts.

The authors all work in the Materials Management program at the Oregon Department of Environmental Quality (DEQ). They are engaged on a variety of projects that advance Oregon toward achieving its 2050 vision for materials management.

Minal Mistry focuses on business (producer) engagement projects and led DEQ’s attributes research with Franklin Associates. David Allaway is a senior policy analyst. Peter Canepa primarily leads life cycle assessment projects. Jonathan Rivin is a materials evaluation specialist focused on public procurement.

For questions, contact [email protected].