Nine robots and seven optical sorters will operate at a mixed-waste processing facility coming to South Carolina. Meanwhile, a separate large mixed-waste MRF is progressing in Maine.

RePower South project

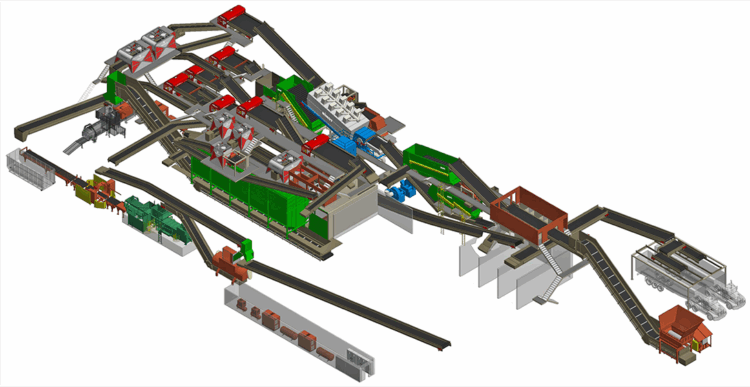

Eugene, Ore.-based recycling equipment company Bulk Handling Systems (BHS) announced it will provide equipment for the Berkeley County Recycling and Recovery Facility, under construction in Moncks Corner, S.C.

When it opens early next year, the facility will process 50 tons per hour of mixed waste from Berkeley County. It will separate recyclables for marketing and prepare non-recyclable materials for use as energy generation. The project is being undertaken by North Charleston, S.C.-based RePower South (RPS), which describes itself as “an advanced recycling, recovery and reuse company.”

“China’s National Sword policy has left many communities contemplating how to best manage recycling with some areas in the US currently landfilling papers, plastics and valuable commodities that had previously been recycled,” according to a BHS press release. “The RPS facility is designed to maximize value from the county’s mixed-waste stream by recovering all recyclables rather than only those placed in a recycling bin.”

It will also recover non-recyclable papers and plastics for production of what’s called “ReEngineers Feedstock,” which is sold to multiple industries that burn coal.

The facility will use NRT optical sorters and Max-AI Autonomous QCs, robots with artificial intelligence. They’ll help clean the fiber stream of contaminants without the need for manual sorters. The robots will also be utilized in each sorting position on the container line.

Fiberight facility

In a separate project, a 180,000-ton-per-year mixed-waste facility is coming to Hampden, Maine. The initiative is spearheaded by Maryland-based Fiberight LLC.

Financed by $45 million in tax-exempt bonds and $25 million in private equity, the facility will serve 83 municipalities and other public entities in eastern and northern Maine, according to a press release from SCS Engineers, which was hired to work on the project.

The facility will separate recyclable commodities for sale and generate clean cellulose, engineered fuels and biogas from non-recyclable materials.

It is expected to start accepting mixed waste from municipal customers during the second quarter of this year.