Courtesy of Stina Inc.

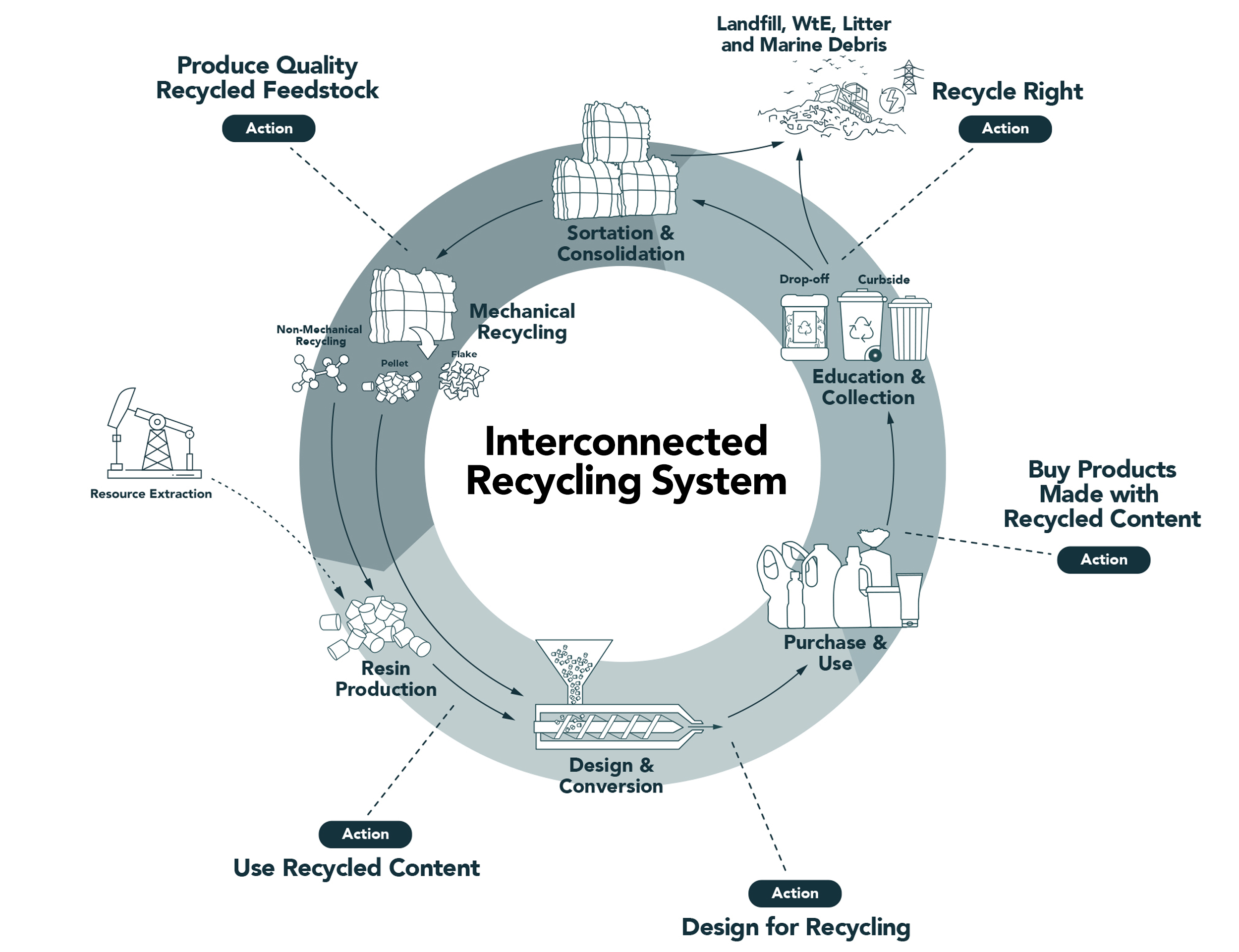

Stina Inc. collects data at a critical step in the plastic recycling value chain—from recyclers. These are companies that purchase and process scrap plastic into feedstock for remanufacturing. They are the engines of the recycling economy. While not the whole story, the data collected at this point in the value chains gives us an aggregated assessment of the total volumes of material recovered for recycling and acquired by markets for processing.

Measuring plastics relative to other materials and actions, along with benchmarking data throughout the value chain, is needed to deliver the insights for businesses and people to make continuous improvement and better choices to protect resources. Measuring where we are is essential if we are to implement strategies that support the recycling economy and ultimately the emergence of a circular economy.

Materials like paper, metal, glass and plastics have vastly different methods to measure what’s generated and what’s recycled. All materials face gaps in information available to fully capture how much gets generated and is available for recycling. In addition to production of goods in the United States, there is a significant amount of material entering and exiting the country on trucks, ships and planes carrying unfinished and finished goods and not everything produced and imported is used and discarded in that given year.

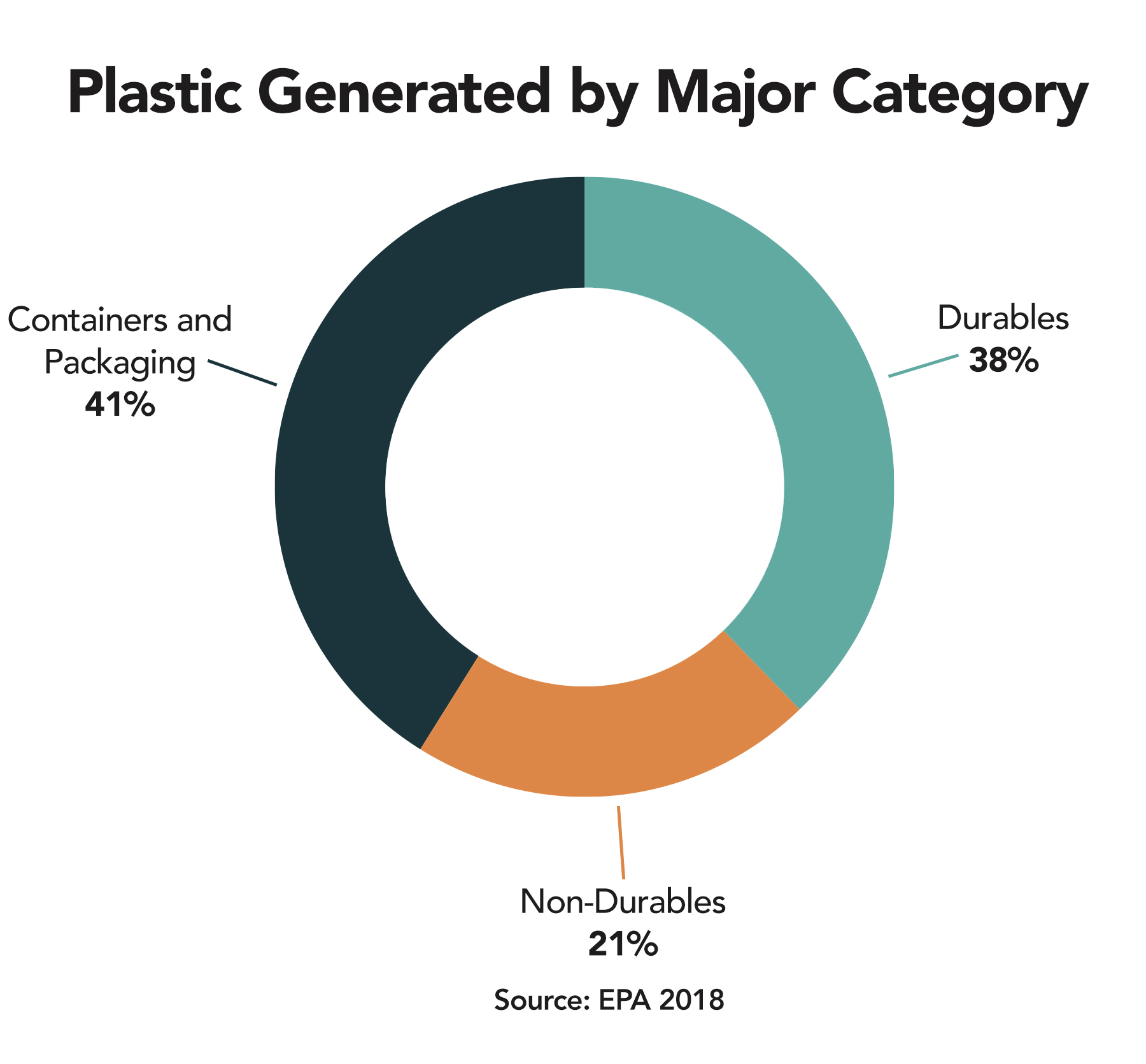

Based on the 2018 Advancing Sustainable Materials: Facts and Figures Report (Facts and Figures), EPA reported generation of plastic materials in three main categories: Durable Goods (38%), Non-Durable Goods (21%), and Containers and Packaging (41%), which are important distinctions for deployment of solutions. Another important distinction, and a challenge related to available data, is a clear understanding of the amount of material generated from residential (or individual use) versus commercial use.

Consistent, Transparent Data Reporting

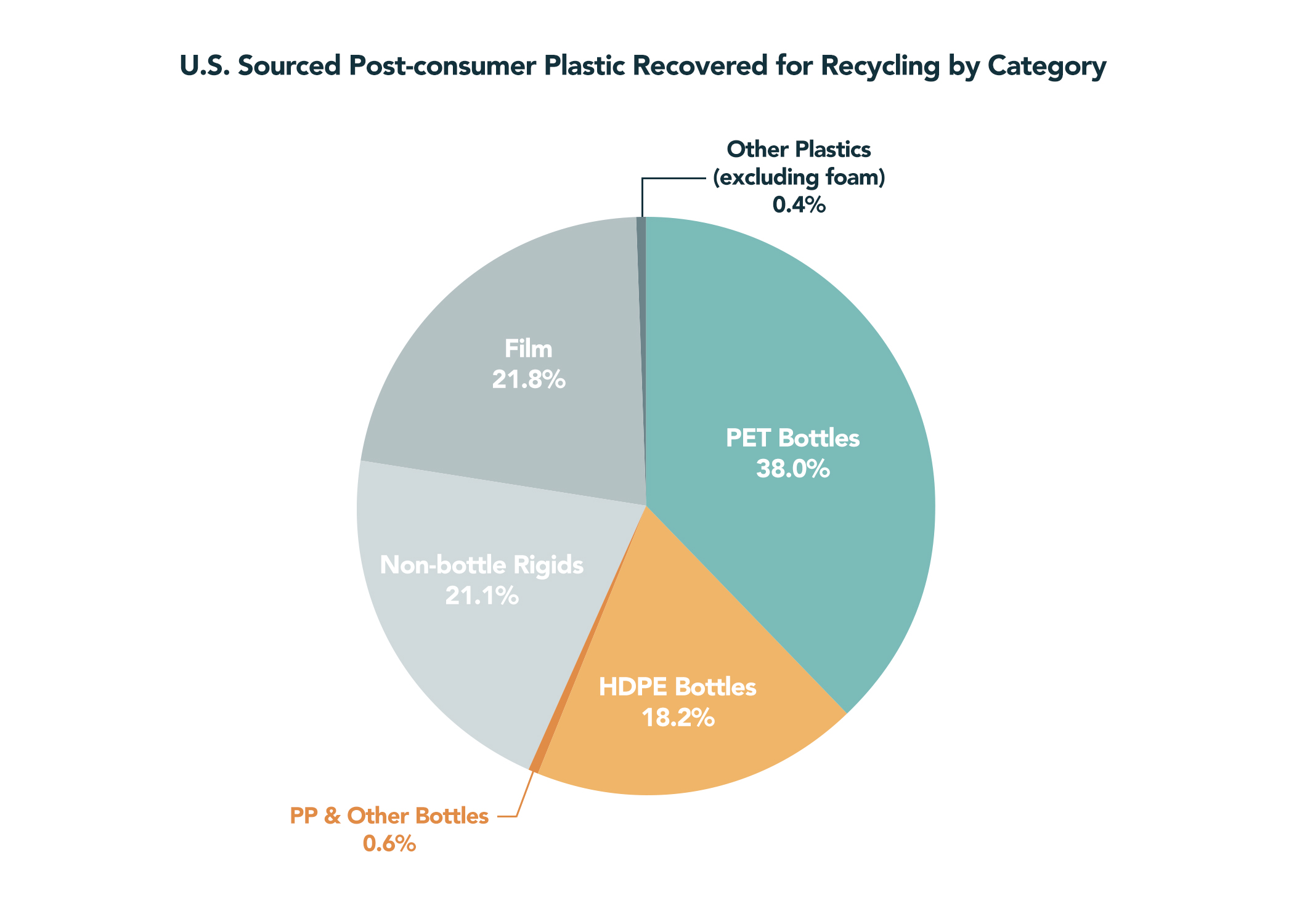

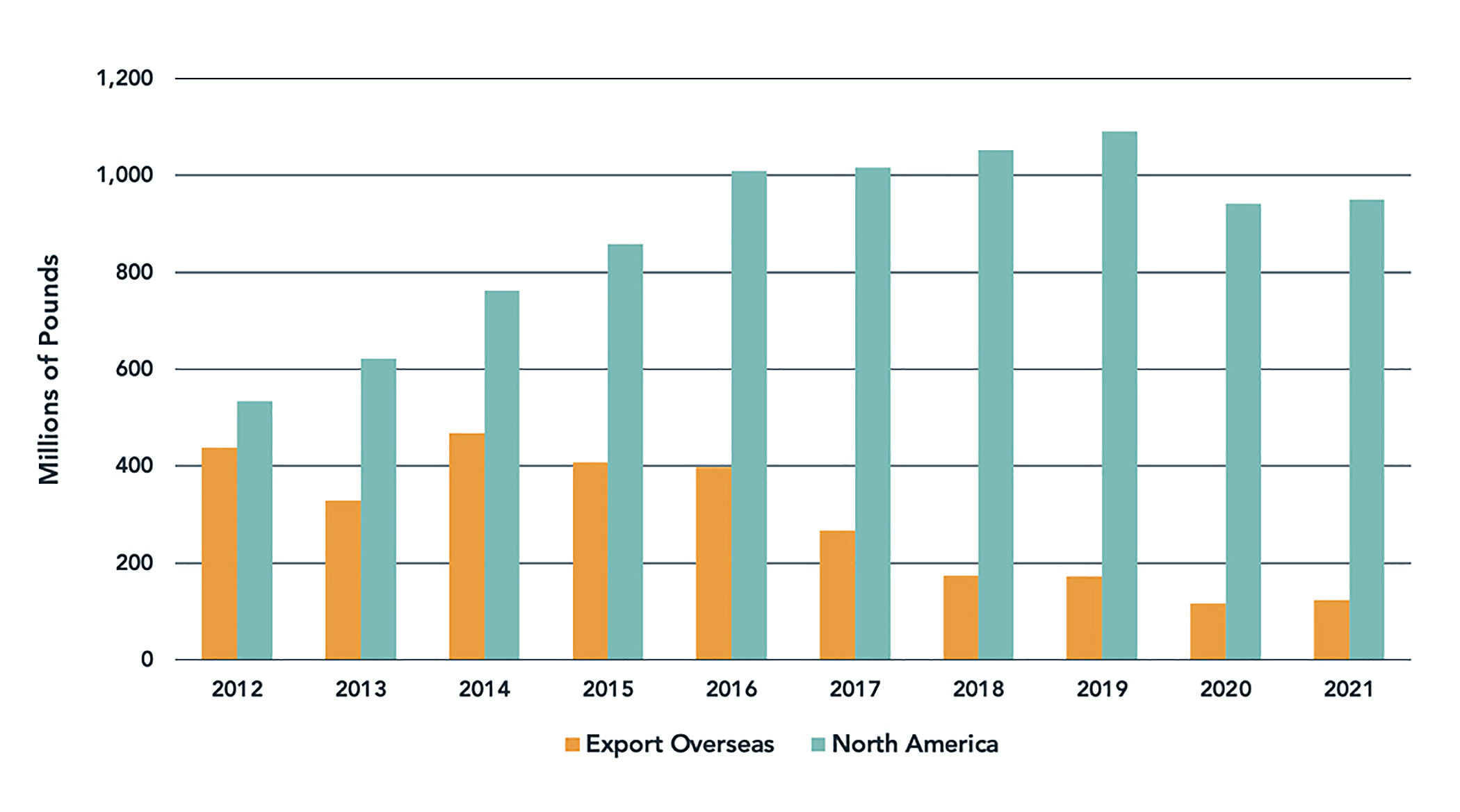

Stina Inc. surveys recyclers (plastic reclaimers), exporters and other key players in the value chain to gather data on the pounds recovered for recycling. Once various items are collected (e.g., through curbside programs, drop off or sourced-separated by businesses) and consolidated for market, reclaimers or exporters (who sell to reclaimers overseas) acquire scrap plastic to process mostly into post-consumer resin, flake or other forms of feedstock to sell to manufacturers or for use directly in new products.

The data Stina Inc. gathers and reports has provided the consistent source of information for the pounds of post-consumer (and post-commercial) plastic recovered for recycling in the United States (and Canada). For nearly two decades this data contributed to the EPA’s determination of the recycling figure for the plastic recycling rate in their annual Facts and Figures reports on waste, recycling and composting. Unfortunately, there hasn’t been an update to that report since the 2018 data was published. Since then, various organizations have generated their own estimates, which will vary depending on methodology used.

How Data on Plastic Recycling is Available to the Public

Stina Inc. continues to track many key data sets and thanks to study sponsors, the pounds of post-consumer plastic recovered for recycling are made publicly available. The U.S. Post-consumer Plastic Recycling Data Report (2022) can be accessed through the Plastic Recycling Data Dashboard on CircularityInAction.com. This data is used in policy development and business planning by analysts, educators, and many other stakeholders.

The data gathering for the U.S. Post-consumer Plastic Recycling Data Report takes the better part of a year. Trust developed through years of relationship-building, neutrality in the marketplace, and strict confidentiality standards enable Stina Inc. to achieve the high participation rate from companies in a voluntary survey.

Stina Inc. developed and utilizes a secure internal information management system to track the marketplace. To ensure accuracy of the data provided and to prevent double- counting, Stina Inc. conducts follow-up calls with respondents. More details on the Methodology, Gaps and Assumptions are detailed in the public report, available through the Plastic Recycling Data Dashboard on CircularityInAction.com.

Getting Granular

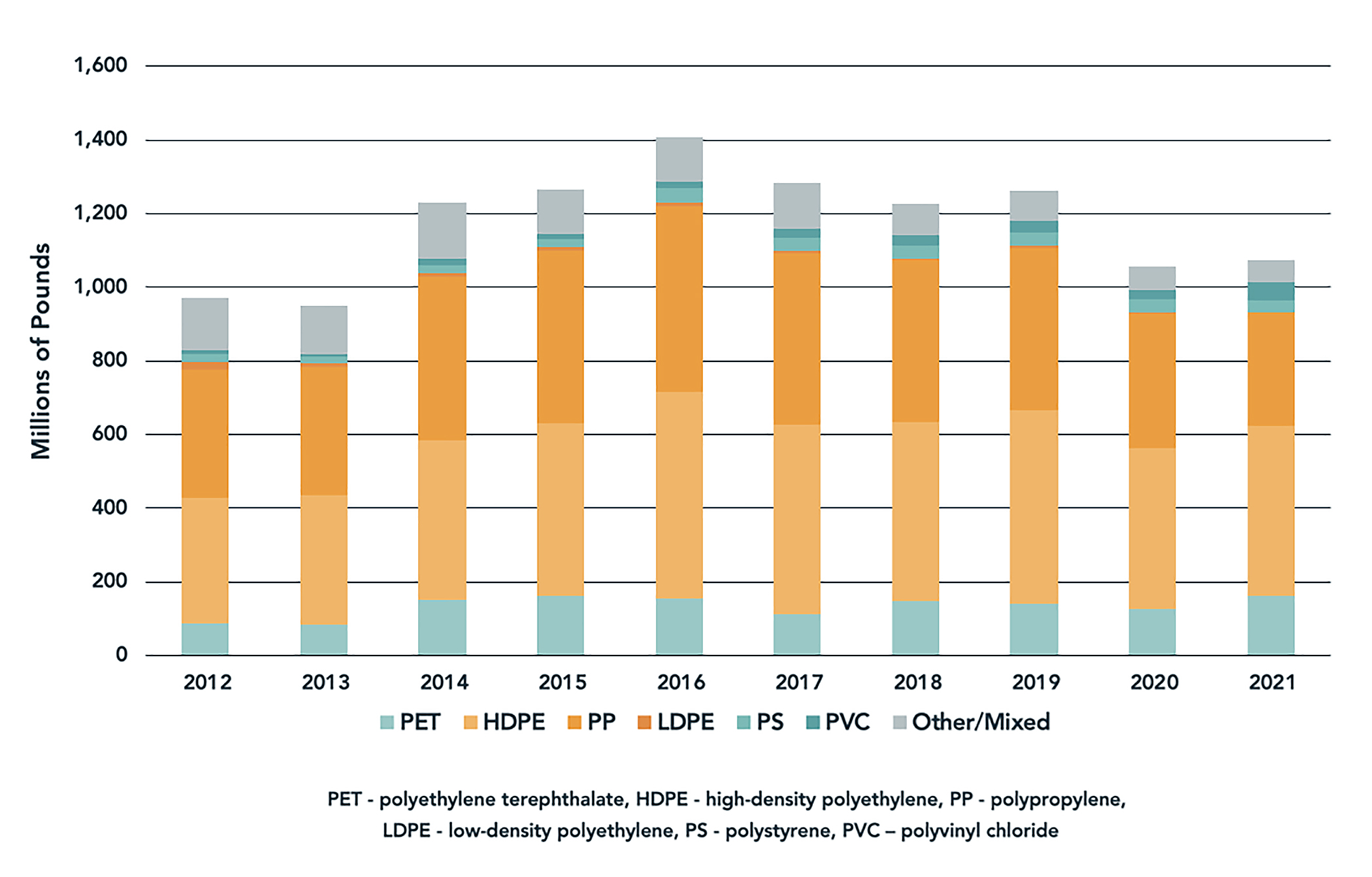

Beyond gathering data on the commodities recovered for recycling, it’s important to have more granular segmentation of the data by resin and product type, particularly where traded commodities are a mix of product types and resin. Stina Inc. completed a National Bale Composition Study in 2022, as an update and expansion of previous studies. The data from the audit enables us to break out the commodities acquired by resin and product type (e.g., PP bottles versus PP non-bottle rigids) and to track the changes in the material stream over time. The primary purpose of the Bale Composition Study is to apply it to the annual study, but it also serves as important insight for industry. Beyond the insight conveyed through the annual plastic recycling report, bale audit details are available through Stina’s Insight Services (StinaInc.com). A new bale audit study is slated to kick off soon.

Collaboration and Good Data Are Essential for Progress

Collaboration and Good Data Are Essential for Progress

Collaboration among industry, government and others as well as long-term planning are essential in the management of resources for future generations. Good data hinges on transparent methodologies and standard (or complementary) use of categories across studies. One example is utilizing the APR Guide for Plastic Sorting—Best Management Practices to support harmonization in waste composition studies or other data collection for plastic, which could help yield a much clearer picture on the national level.

Organizations like the National Renewable Energy Lab (NREL) recently published a report focused on the lost value of landfilled plastic (2022) as well as a report on losses from landfilled cardboard and paper (2023). And there are many other organizations working to fill data gaps to aid in better decision-making from upstream material choices to recycling solutions.

Shed Light on Misinformation

Shed Light on Misinformation

There has been a heavy focus on recyclability in recent years, which is essential for recycling. However, we also need to direct attention and resources to other critical parts of the recycling chain, including the use of post-consumer recycled content and increased collection of recyclable items. Greenwashing, or misleading customers about the environmental benefits of a product, is harmful, and it is also harmful to discourage the recovery of resources by casting doubt about recyclable materials. Misinformation in any form is damaging to the collective goal: managing resources sustainably so we may sustain life on Earth.

Recycling is Part of the Solution & We Need Greater Measurement

Recycling is Part of the Solution & We Need Greater Measurement

The year over year trends vary, but this much is clear: The gap between the amount of plastic produced and the amount recycled continues to grow. We can’t just recycle our way out of the current plastic waste problem. We need to reduce the amount of plastic and all materials we produce that become waste. That said, we also must recycle what we produce to create circularity. If the true cost of production and waste were accounted for, recyclers could have positive returns on investment for the new capacity needed to close the massive delta between virgin resin production and reclamation capacity. In the absence of new and critical economic policies to support this, brands and consumers alike can support more plastic recycling by supporting the companies producing post-consumer resin and using recycled content in products like those listed in the Buy Recycled Products Directory on RecyledProductsDirectory.org.

We will continue to work for better collaboration, more recycling data and more consistency in measurement points for recycled plastics and other commodities as a core underpinning of the actions needed to elevate recycling rates. With more use of recycled content and participation in recycling of recyclable items, we look forward to being able to report how recyclers are closing the delta between virgin resin and post-consumer resin production.

Nina Bellucci Butler is the CEO and Stacey Luddy is the COO of Stina Inc., which is a mission-based research and technology company providing unbiased guidance to governments, industry and NGOs in the movement toward circularity, navigating choices to preserve and recover the resources we use. The reality of plastics and plastic recycling has been a key focus of Stina’s work.

This article appeared in the Spring 2024 issue of Plastics Recycling Update. Subscribe today for access to all print content.

Collaboration and Good Data Are Essential for Progress

Collaboration and Good Data Are Essential for Progress

Shed Light on Misinformation

Shed Light on Misinformation Recycling is Part of the Solution & We Need Greater Measurement

Recycling is Part of the Solution & We Need Greater Measurement