Electronics and appliances present an attractive source for reclaimed plastics, but technical challenges can often inhibit recovery. Many of the e-plastics are black, which can make separation by polymer difficult.

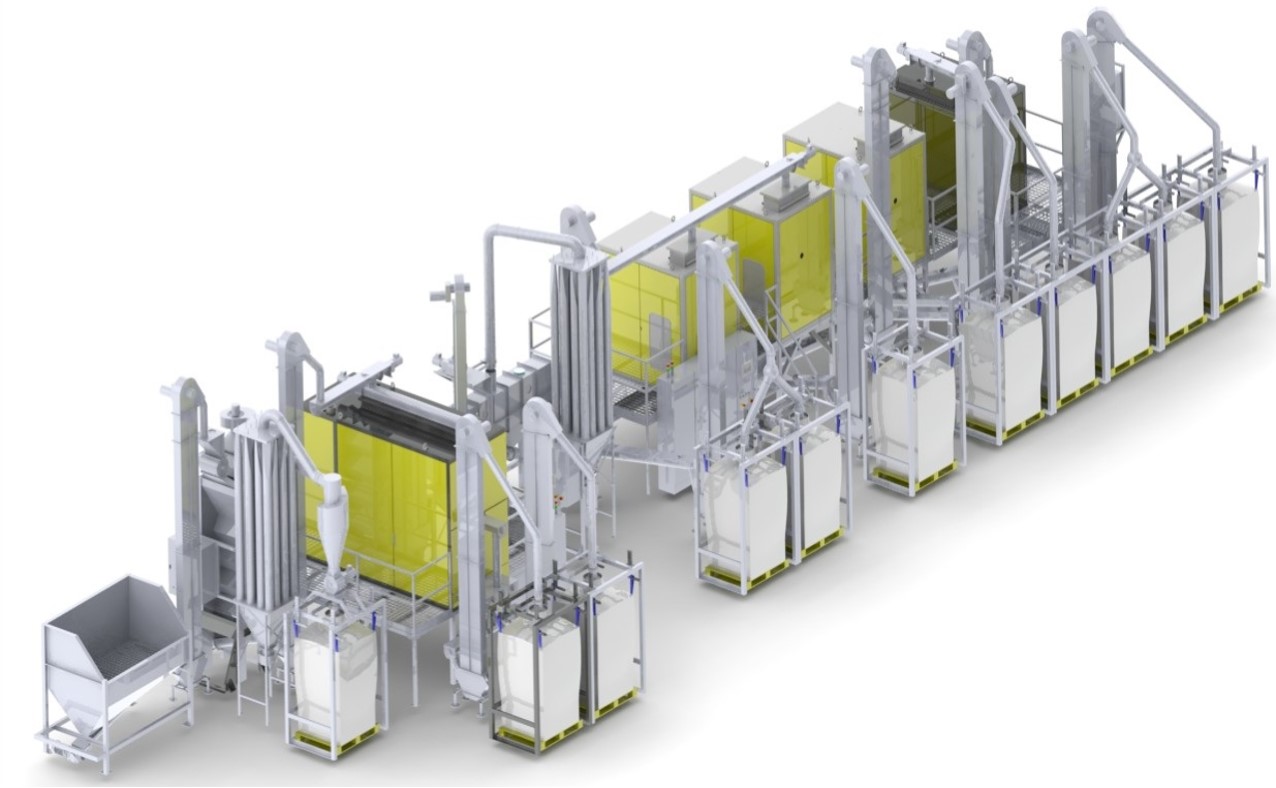

Germany-based company Hamos supplies a sorting line for plastics reclaimers looking to sort black plastics from other black plastics in those end-of-life devices.

The system is capable of removing a variety of contaminants, including rubber, wood, silicone, dirt and more, while also recovering separate black PS and black ABS stream, according to Hamos.

“Even completely black-colored fractions can be separated at the lowest sorting costs with purities of PS and ABS of better (than) 98.5 percent, something that other separation systems cannot do,” said Rainer Koehnlechner, managing director of Hamos.

The first step in Hamos’ full separation line involves pretreatment of the material, which includes screening by size, de-dusting, removal of heavy materials and the elimination of metals.

After that, float-sink techniques are used. Using a salt solution, the tank is able to sink plastics containing flame retardants to the bottom for removal, while allowing non-flame retardant PE, PS, ABS and PP/PP20 (polypropylene 20 percent talc-filled) to float. Then, using the float-sink process with freshwater, PE and PP float while PS, ABS and PP20 sink to the bottom.

The final pre-treatment step involves granulation, reducing plastics to less than 10 millimeters in size, and drying of material. The equipment will dry plastics but leave wood wet, which aids in removal of wood in the next step: electrostatic separation targeted at plastics.

Each of the company’s EKS electrostatic separators can sort up to 1,650 pound per hour of material, separating black plastics from other black plastics. Via the use of triboelectric charging, the equipment can separate PS from ABS and PP20. According to Hamos, it can achieve purities of 98.5 percent in the resulting PS stream and 99 percent in ABS stream.

The company says the sorting technologies can be used to recover plastics from a printer or a toner cartridge, for example. The e-plastics would go through the line, generating streams of PS and ABS regrind that can then be extruded and compounded and sold back to an electronics manufacturer for use in new products. The use of recycled content helps the manufacturer qualify for EPEAT ratings, a recognition of a product’s comparably lighter environmental impact. That, in turn, helps them sell products.

The company is using its technology in a demonstration plant in Germany. That plant is run by Hamos’ sister company, Wersag, which reclaims and sells PS, ABS and PP regrind from end-of-life electronics and appliances streams.

“Our know-how in WEEE (waste electrical and electronic equipment) plastic separation is based upon the experience with our own plant,” Koehnlechner said.

“Our know-how in WEEE (waste electrical and electronic equipment) plastic separation is based upon the experience with our own plant,” Koehnlechner said.

He noted other potential separation applications for the EKS electrostatic separators. For example, he said it would be used to eliminate PVC from PET flakes in post-consumer bottle recycling, or it can separate polyolefin mixtures into clean streams of HDPE and PP.

Koehnlechner said Hamos can provide full e-plastics lines or single EKS electrostatic separators.