A new partnership between rare earth processor HyProMag USA and electronics recovery firm Intelligent Lifecycle Solutions aims to secure and sustain domestic access to rare earth magnets used in everything from electric vehicles to smartphones to missile systems.

The agreement, finalized earlier this year, positions HyProMag USA to receive a consistent supply of neodymium iron boron (NdFeB) magnets and components from ILS facilities in South Carolina and Nevada. These feedstock materials, sourced from end-of-life hard disk drives and other equipment, will be preprocessed using automated extraction technology before being sent to HyProMag USA’s advanced recycling facility, planned for construction in the Dallas–Fort Worth region.

That facility, expected to come online in 2027, is projected to process 750 metric tons of neodymium-iron-boron (NdFeB) magnets and more than 800 metric tons of related co-products each year within five years of operation. The company anticipates creating around 90 to 100 skilled manufacturing jobs and producing enough recycled rare earth material annually to significantly offset U.S. reliance on foreign imports.

The joint venture, a 50–50 split between CoTec Holdings and HyProMag Ltd, aims to commercially utilize a hydrogen-based short-loop magnet recycling process originally developed at the University of Birmingham in the United Kingdom. HyProMag Ltd is a spin-off of the university and is now fully owned by Maginito Ltd, in which Mkango Resources holds a controlling interest.

Jon Godfrey, director of Intelligent Lifecycle Solutions and a longtime advisor to HyProMag, said the new partnership is the result of nearly a decade of collaboration across the Atlantic.

“Our business is in the e-waste stream. We’re an R2-accredited recycler and our job is to go out and acquire material to feed the various HyProMag businesses,” Godfrey said. “The announcement that’s just been made is by far the most significant, but we’re also operating with HyProMag in the UK and hopefully soon within Europe as well.”

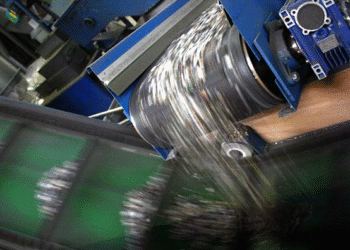

The recycling method HyProMag is advancing uses hydrogen gas to break down magnets into powder form while simultaneously demagnetizing them. Godfrey said the process is both efficient and environmentally sound.

“It uses hydrogen to get into the grain boundaries of the magnet and it can break the magnet down. It also demagnetizes the magnet in the process,” he said. “It’s beautifully simple, elegant and sustainable.”

“In the past, every time a rare earth magnet hit one of our shredders, it would turn into horrible magnetic dust that would get into every gearbox and piece of electrical switchgear. It was causing huge challenges to the recycling industry,” he said.

The hydrogen process avoids these issues and allows for clean separation and reuse of magnetic material, reducing embedded carbon by more than 88% compared to conventional chemical recycling methods, such as solvent extraction or high-temperature metallurgical processes, according to company estimates.

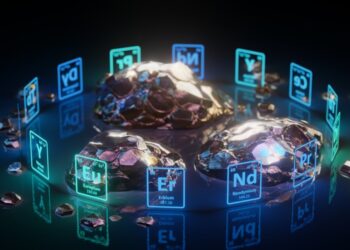

Crucial materials, but rarely recovered

For the average consumer, rare earth magnets are nearly invisible yet ever-present. These small, powerful magnets are essential components in power steering systems, generators, hard disk drives, smartphones, electric toothbrushes and virtually every electric motor found in modern appliances and vehicles.

“Every electric vehicle, every generator, every valve and pump actuator relies on these magnets. Even internal combustion vehicles depend on high-performance motors and pumps,” Godfrey said. “There are up to 70 rare earth motors in a modern vehicle. Every power steering module these days is a rare earth motor.”

Despite their importance, these components are rarely recovered. Godfrey pointed out that the virgin raw materials are often cheaper than the cost of recycling, which has discouraged investment in recovery infrastructure. He said that dynamic is not sustainable.

“We throw away a huge proportion of these materials. It’s ludicrous. They’re challenging and difficult to recycle, so we discard them because it’s not cost-effective. But the value is there. We just haven’t been pricing it properly,” he said.

HyProMag’s short-loop model (not breaking magnets down into their raw elements) is designed to intercept rare earth magnets before they go through destructive processes like shredding. This approach allows the company to preserve material integrity and manufacture new magnets from recovered powder, something most recyclers cannot do.

“We’re not just a recycler. We’re actually able to produce magnets,” Godfrey said. “If you look at HyProMag’s website, you’ll see case studies where magnets have been made and put into various vehicles using this exact process.”

Intelligent Lifecycle Solutions is playing a central role in sourcing the raw materials for the new facility. The company owns and operates electronic recycling sites in Williston, South Carolina and Sparks, Nevada. It is certified to ISO 14001:2015 and ISO 45001:2018 standards and holds R2v3 accreditation.

A feasibility study released in March 2025 estimates that the Dallas–Fort Worth facility could eventually process over 1,500 metric tons of NdFeB annually over a 40-year lifespan. An ISO-compliant carbon footprint assessment found that the process produces just 2.35 kilograms of CO2 equivalent per kilogram of NdFeB block, well below the emissions associated with virgin material production.

Geopolitical backdrop

The potential implications extend beyond environmental metrics. China dominates global refined rare earth supply and rare earth magnet production, accounting for roughly 90% of refined output and about 90% of magnet production, according to both the International Energy Agency and industry analysts. That level of concentration has triggered concern in both Washington and Brussels as demand for rare earths in clean energy, defense and digital technologies continues to surge. Additionally, China has restricted access to its rare earth supply at times, including recent restrictions enacted amid heightened global trade tensions.

“There’s a huge sensitivity to strategic materials and mineral supply,” Godfrey said. “When the President of the United States is talking about magnets in public discussions, you realize this has gone right to the top.”

Godfrey said HyProMag’s efforts to build domestic capacity in the U.S., UK and Germany are part of a broader attempt to reclaim control over a critical supply chain that was once dominated by Western innovation.

“These magnets were invented in the mid-1970s. A lot of the original research took place in the UK and the U.S. Over time, we allowed that to go abroad, and now we’re dependent on other geopolitical forces. That’s a very uncomfortable position to be in,” he said.

Looking ahead, Godfrey said HyProMag’s model could be applied well beyond magnets, influencing how society handles other critical materials such as batteries and plastics. “It took 40 years to develop the aluminum recycling process,” he said. “We’re trying to do that with rare earths in half the time.”