When municipalities, manufacturers, and procurement teams talk about recycled plastics, the conversation often centers on meeting sustainability targets. Increasing recycled content, reducing environmental impact, and complying with extended producer responsibility regulations are all vital goals in the drive toward a circular economy. Yet there is another imperative that is less frequently discussed and potentially just as consequential: performance risk.

Understanding recycled plastics solely through a sustainability lens is no longer sufficient. Today’s marketplace demands that recycled materials not only carry a positive environmental story but also deliver reliable, predictable performance. This is where testing comes in, not just as a compliance checkbox, but as a strategic budget protection tool.

Unlike virgin resins, which are produced under tightly controlled feedstock chemistry and melt conditions, recycled streams can vary widely based on their source, collection method, and preprocessing history. Variability in feedstock, thermal degradation during previous life cycles, contamination from paints or adhesives, and inconsistent additive profiles can all influence mechanical performance, processing behavior, and long-term durability.

In real-world procurement, these factors translate into budget risk, from increased scrap rates and production downtime to premature product failures and costly warranty claims.

Testing data provide support for decision-making

Testing is not limited to pass-or-fail decisions. When used strategically, it becomes a decision support system across procurement, design, and manufacturing.

Procurement teams can compare suppliers using quantifiable performance data rather than price alone. Specifications can be written around functional requirements that align with real use conditions. Qualification loops can track the performance of recycled material over time. Pricing and risk sharing can be negotiated based on verified metrics rather than assumptions.

Benchmarking is a key element in this approach. Establishing baseline performance requirements for each application and repeatedly testing against those benchmarks transforms materials selection into a disciplined, evidence-based process.

Testing can guard against hidden costs

Reducing production losses is one of the most immediate benefits of testing. Testing melt flow rate, tensile strength, and environmental stress cracking resistance helps predict whether recycled batches will remain within acceptable processing windows, and help avoid unexpected softness or stiffness in blow-molded recycled HDPE, for example. This information allows operations teams to adjust machine settings or reject problematic material before costly downtime occurs.

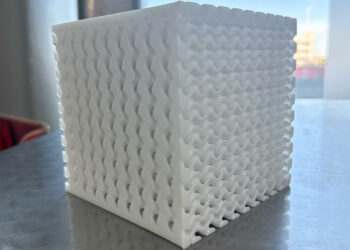

Avoiding premature failures is equally important. A municipality specifying recycled-plastic benches for public parks may focus on the recycled content percentage, but cracking under thermal cycling or prolonged loading can quickly drive up replacement costs. Mechanical testing, combined with accelerated aging simulations, helps ensure that materials will support long-term service without frequent replacement.

Testing also helps lower warranty and aftermarket costs. In applications such as consumer packaging or automotive interiors, recycled plastics must meet dimensional and stress requirements over time. Properties such as moisture uptake or thermal expansion can cause warping or part rejection. Comprehensive testing protocols provide early warnings, protecting future warranty obligations.

Real-world examples: When testing prevented losses

The following examples illustrate how testing links material performance directly to cost control and public accountability.

In one packaging application, early mechanical and thermal degradation testing revealed that recycled polypropylene lost tensile strength after a regrind cycle. Adjustments to blend ratios and stabilizer use restored performance and prevented downstream failures.

In another case, a transit authority evaluating recycled plastic traffic posts introduced impact testing and accelerated ultraviolet exposure. Materials that met recycled-content targets but failed durability requirements were eliminated before deployment to avoid repeated replacement costs.

Testing standards provide a common language for quality

Testing delivers the greatest value when anchored to recognized standards. Methods such as ASTM D638 for tensile properties, ASTM D790 for flexural behavior, and ISO 527 for plastics testing provide consistent frameworks for supplier comparisons and batch qualification.

Supplementing baseline testing with accelerated aging, environmental stress cracking, and thermal evaluation creates a more complete picture of material risk. When testing data supports sustainability claims, organizations gain both regulatory confidence and market credibility.

A future where performance supports sustainability

As recycled content mandates expand, organizations must ensure that sustainability goals do not introduce hidden costs. Recycled plastics should be treated as engineered materials with defined performance requirements, not simply as environmentally preferred options.

Testing enables recycled materials to compete with virgin resins on reliability, durability, and consistency. When performance is validated, sustainability becomes economically viable rather than financially risky.

The future of recycling depends on trust. Trust that recycled materials will perform as expected. Trust that sustainability initiatives will not compromise safety or durability. Trust that budgets will remain protected.

That trust is built through testing. By translating variability into measurable data and linking performance to real-world use, testing allows recycled plastics to meet both environmental and economic expectations. In this way, testing becomes the quiet force that enables circularity to scale responsibly.